On-the-go soil sensors and control methods for agricultural machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

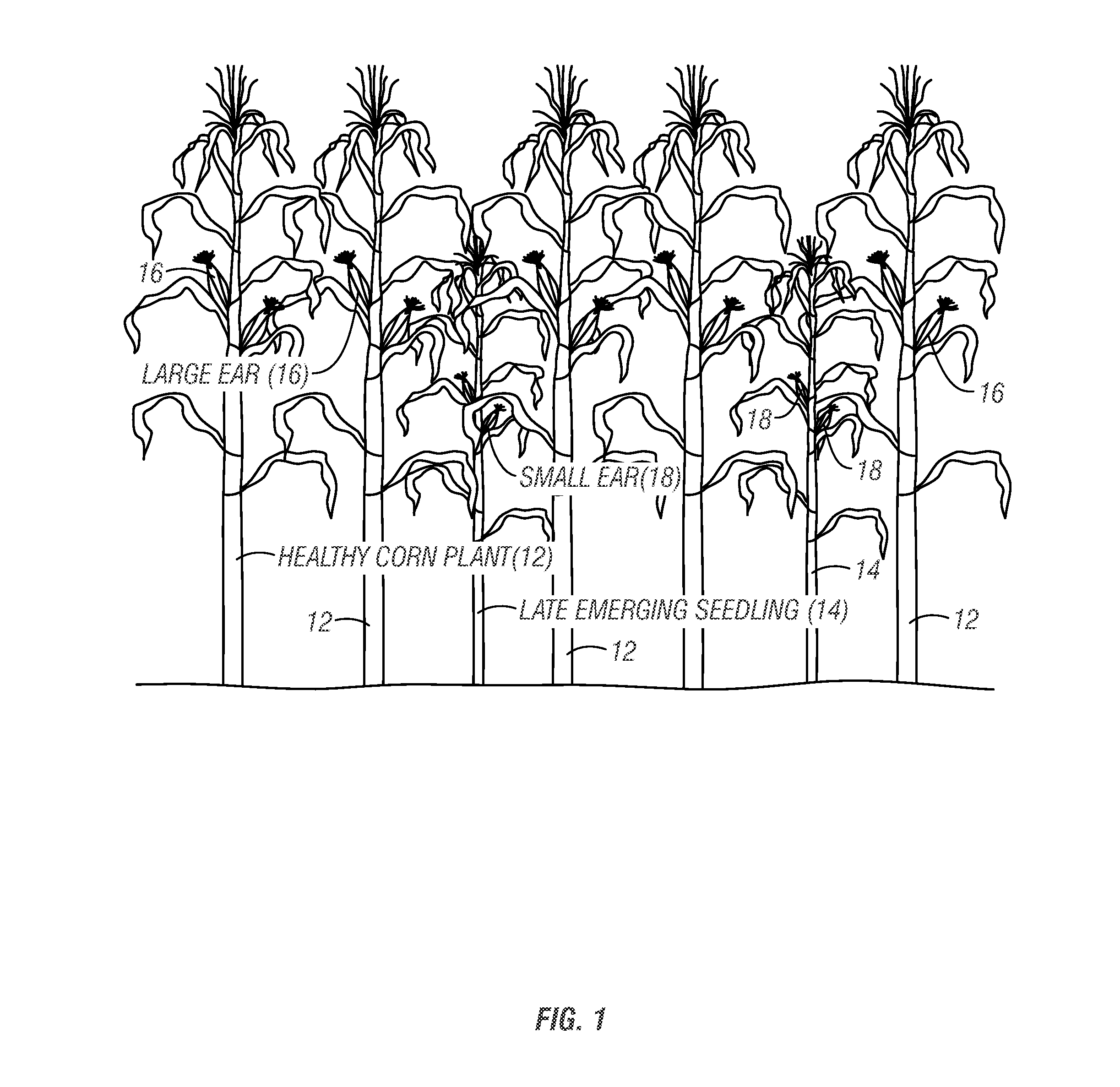

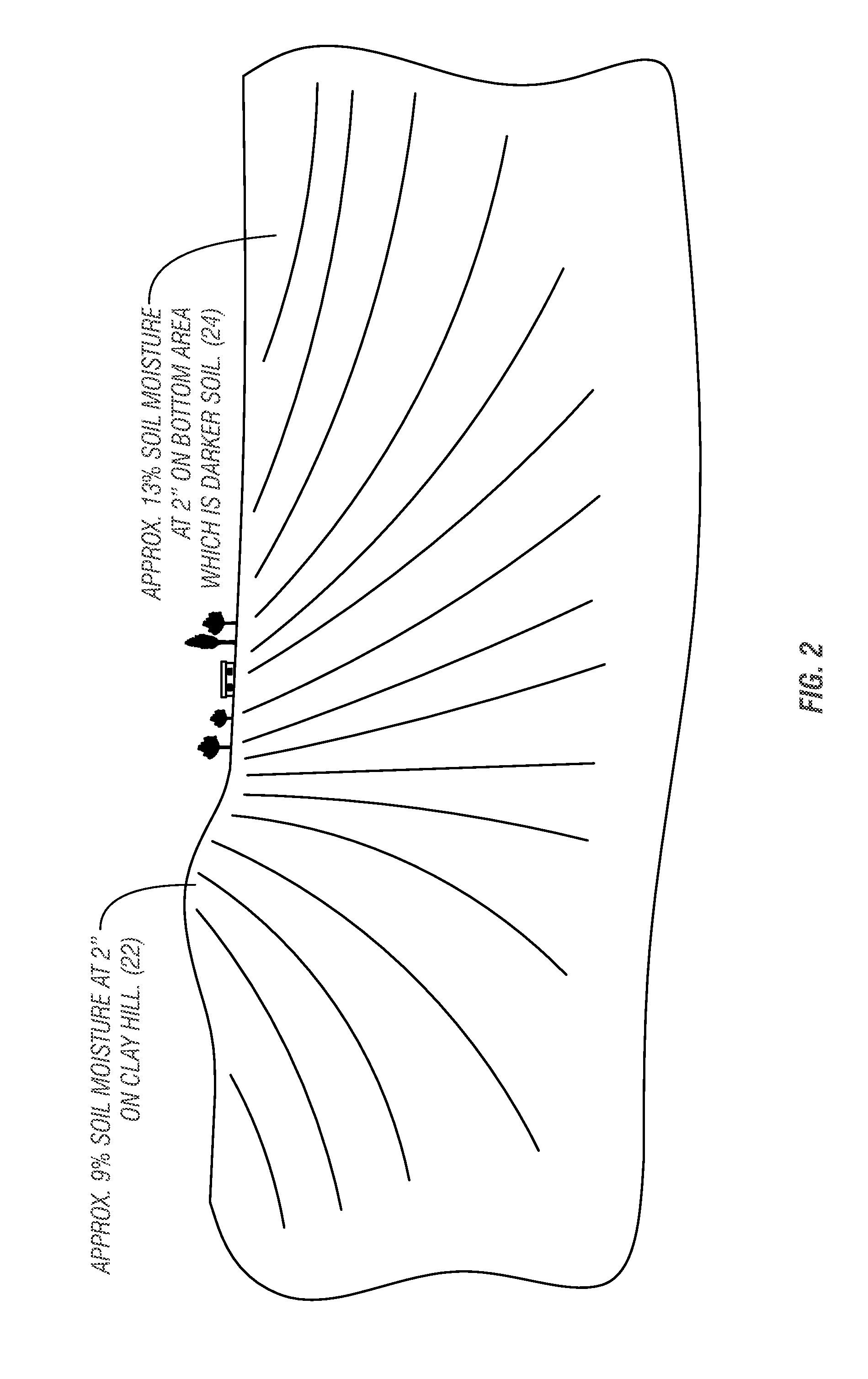

[0052]The present invention includes systems and methods for use in adjusting seed planting depth and row unit down pressure to account for varying levels of soil moisture in a field when planting to minimize occurrences of late emerging corn seedlings.

[0053]FIG. 3 illustrates one example of a system which includes a planter 4 having a control system 5. The control system 5 may include an intelligent control 11 operatively connected to a monitor 2. There may be a plurality of row units 6. For each row unit 6, there is an actuator 8 and sensors 7, 9. The sensors 7, 9 may include a soil moisture sensor, a seed to soil contact sensor, soil temperature sensor and seed trench depth sensor for adjusting seed planting depth and row unit down pressure on-the-go while planting.

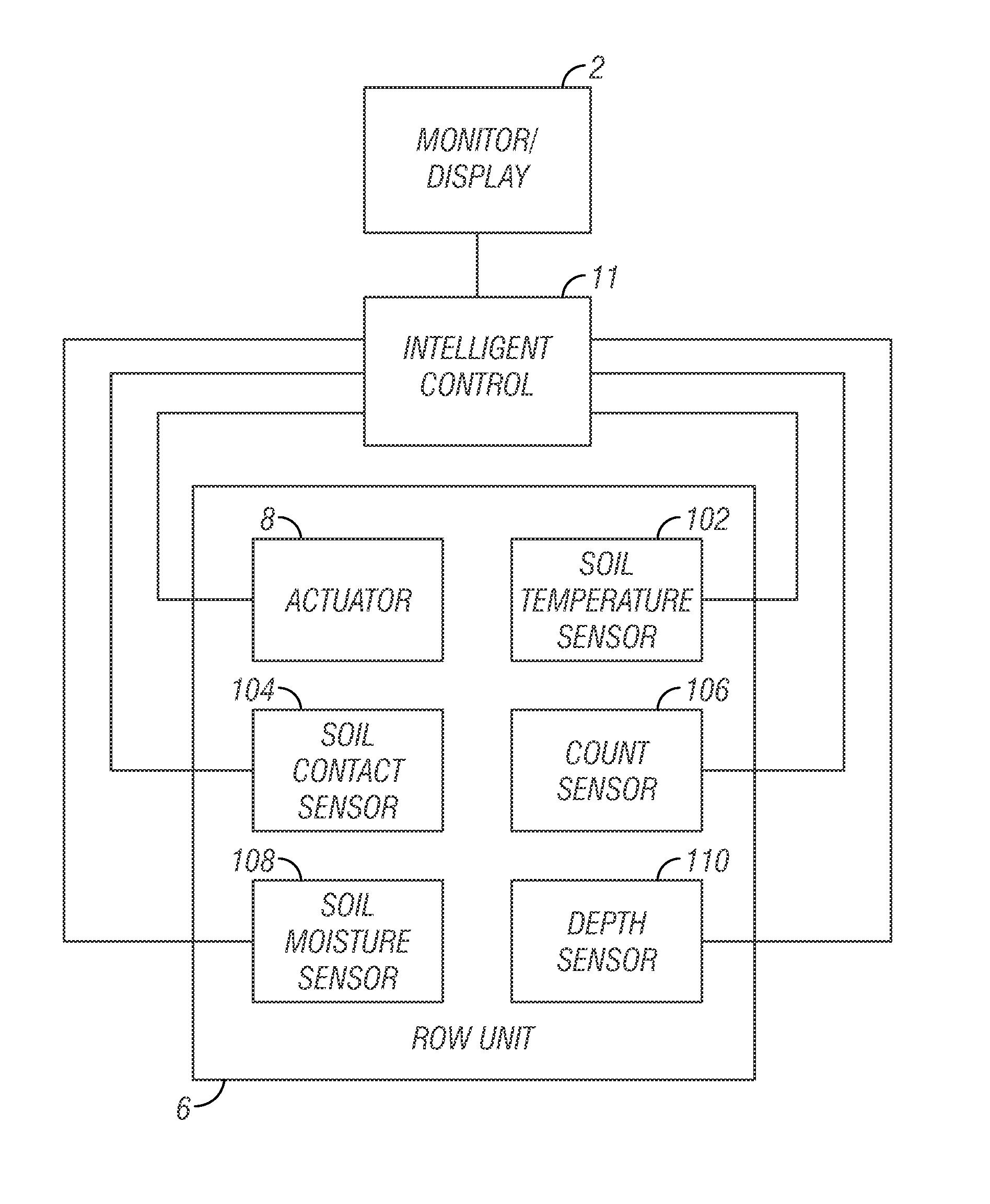

[0054]FIG. 4 illustrates another example of the invention. As shown in FIG. 4, an intelligent control 11 is operatively connected to a monitor or display 2. The intelligent control unit 11 is also operatively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com