Bio-degradable compositions and use thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

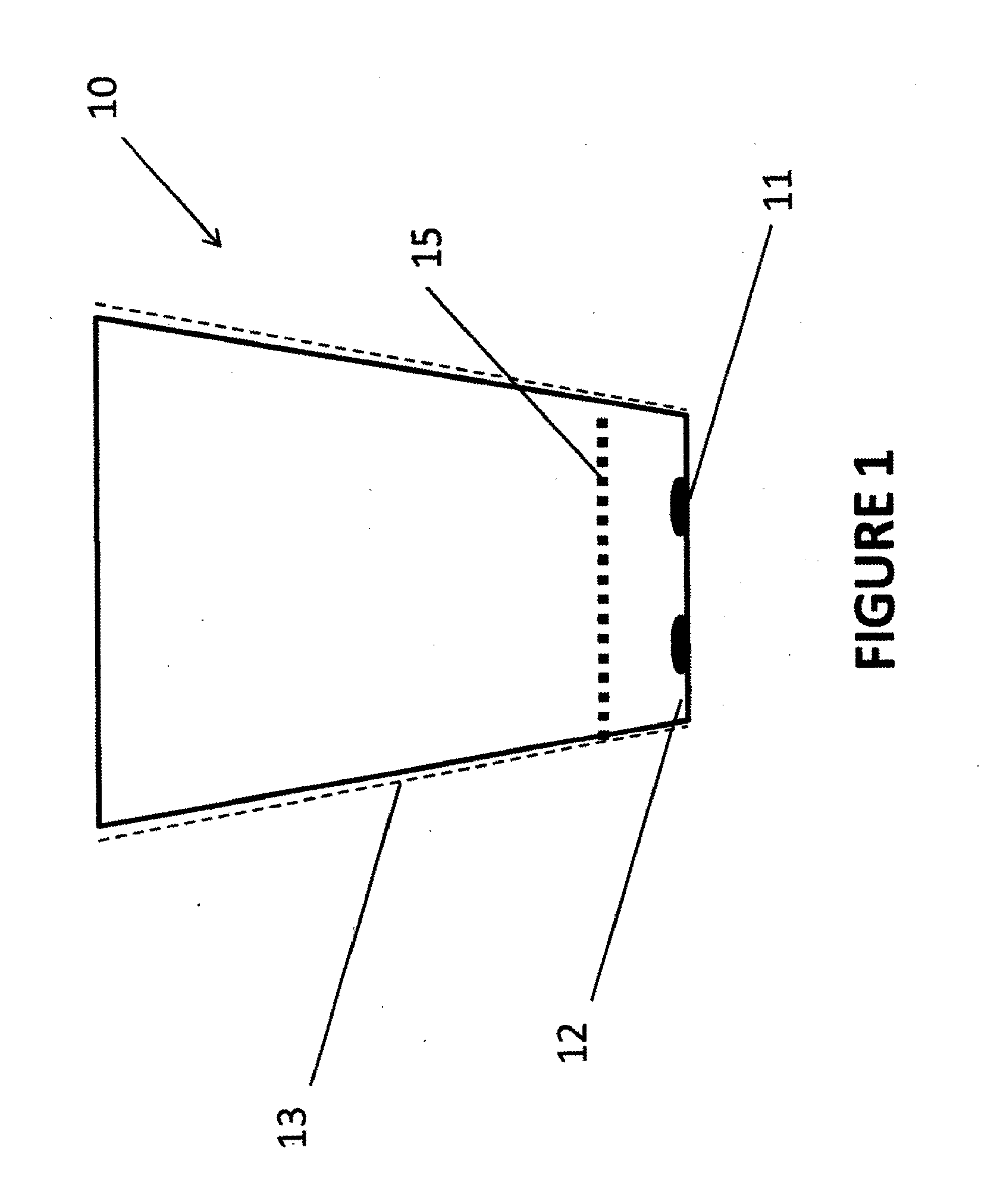

Rooting Plugs

[0068]

Composition I:1 gr PLA40 ml EtOAc10 ml DCM

[0069]Rooting plugs of 2×3 cm were prepared using an Ellegaard system. A finger sized hollow was made in the center of each plug. Each hollow was sprayed with 0.5 cc of composition I using a syringe. Control plugs were left untreated. The plugs were dried in RT over night and a Gypsophila (Baby's Breath) shoot was placed in each of the plugs' hollows. Plugs were irrigated for one month with irrigation from on top.

[0070]Plant Development—Plant development was better in treated plugs. Plants grown in treated plugs had more root mass than the plants grown in control plugs, possibly due to better water retention in the treated plugs.

[0071]Composition stability—Treated plugs were stable after one month in trays. Degradation of treated plugs was observed upon planting in soil (within days of planting).

Composition II0.5 gr PLA35 ml EtOAc10 ml DCM5 ml acetone

[0072]Rooting plugs of 2×3 cm were prepared using an Ellegaard™ system. A...

example 2

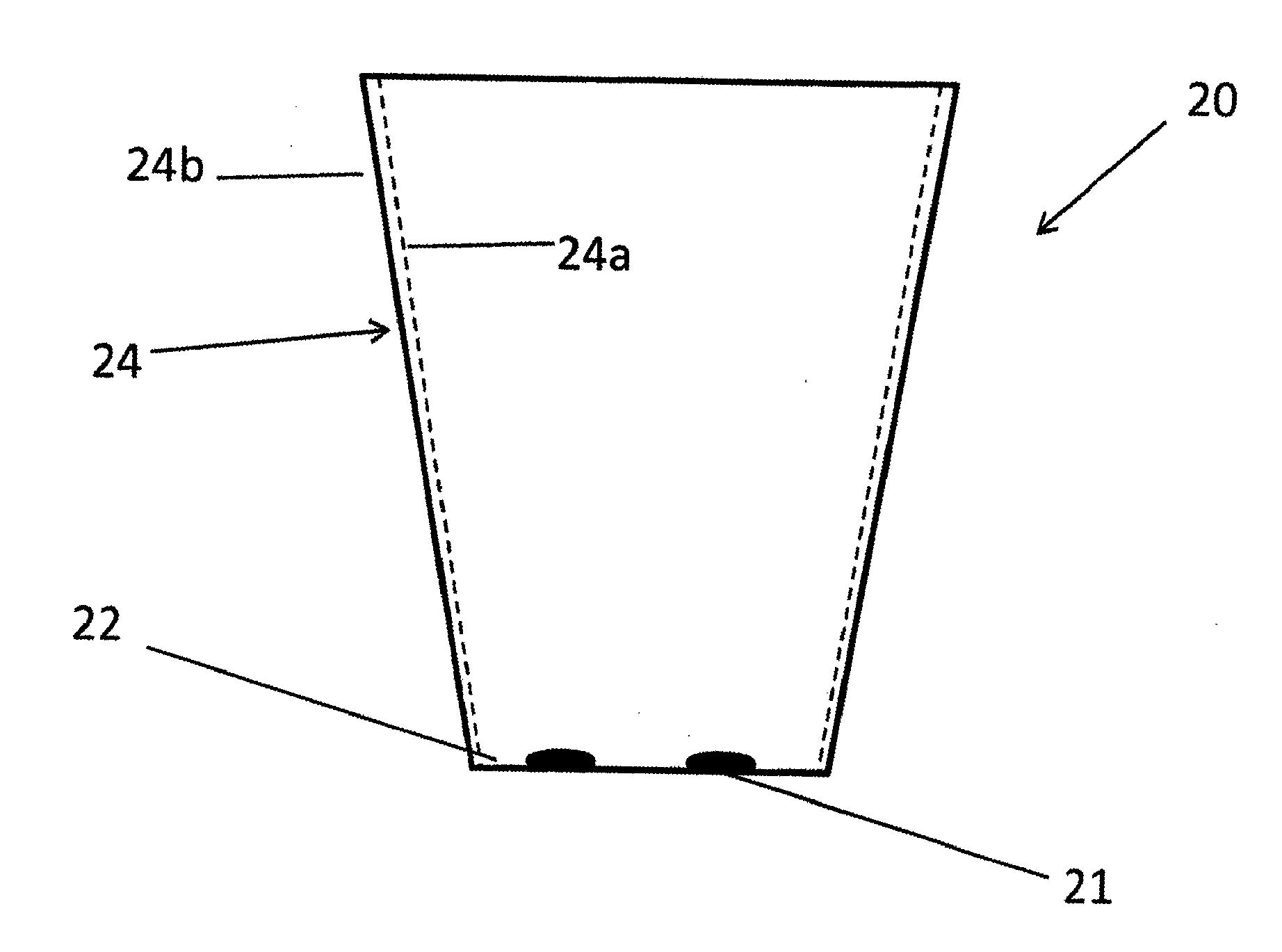

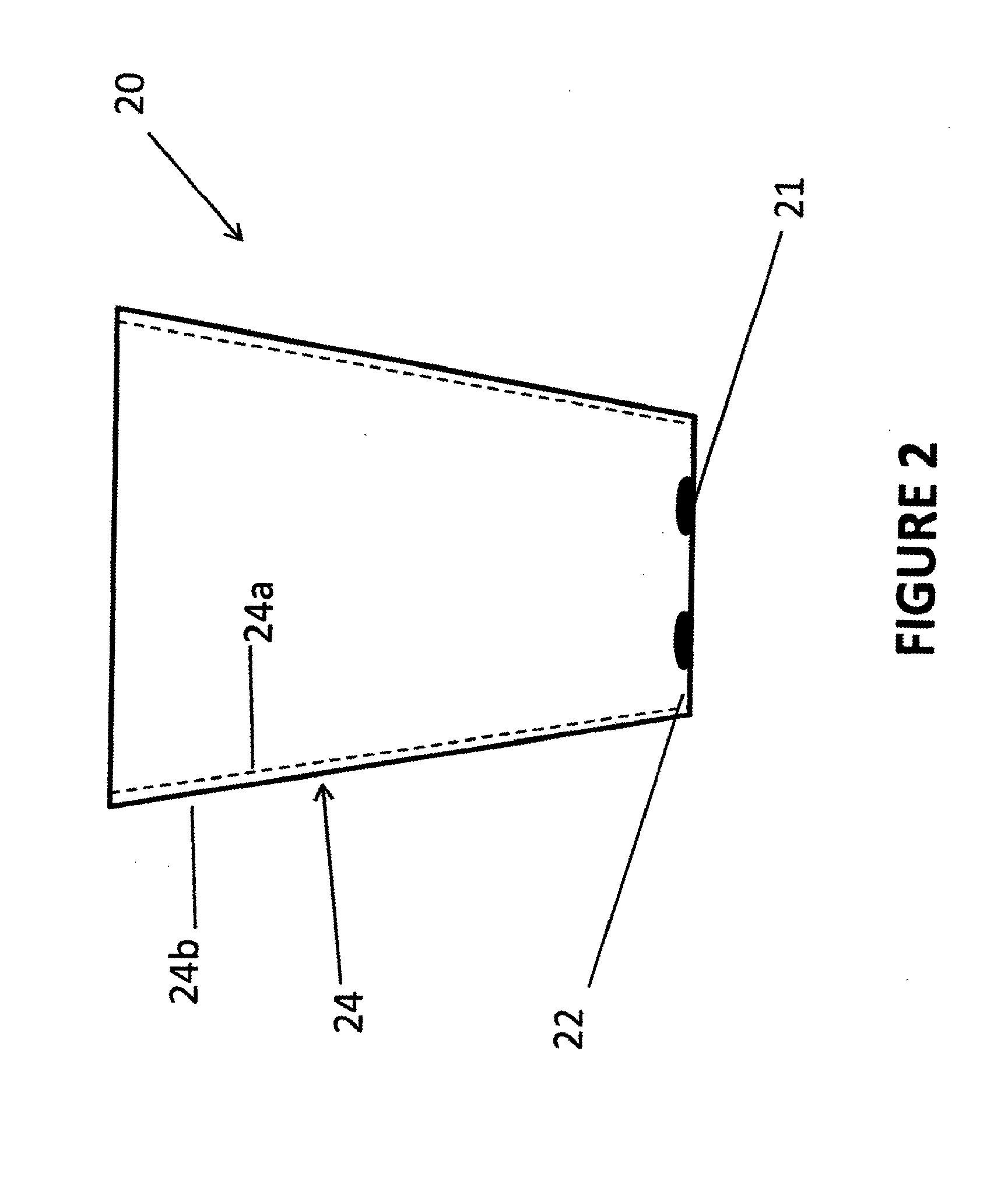

Bio-Degradable Plant Pots

[0076]

Composition III:4 gr PLA160 ml EtOAc40 ml DCMComposition IV:4 gr PLA180 ml EtOAc20 ml DCMComposition V:4 gr PLA160 ml EtOAc20 ml DCM20 ml acetone

[0077]Plant pots (7 cm diameter, made of packed saw dust (50%) and starch (50%)) were immersed in compositions III-V until totally coated. The pots were let to air dry at RT for 30-45 minutes. Coated pots were filled with soil (mostly peat). A shoot of mint plant was planted in the soil filled pots. Pots were irrigated once a day such that the soil was always moist, for three months. The pots were buried in soil after three months.

[0078]In addition to using the compositions to coat the pots, compositions were also left to dry in the beaker to examine their different characteristics when dried films

[0079]Plant Development—no negative effect was demonstrated on growth of the mint plants.

[0080]Composition stability—composition IV dried to form a more elastic film than composition III. Composition V could be dilut...

example 3

Bio-Degradable Plates

[0085]

Composition VIII:0.1 gr PLA45 ml EtOAc5 ml DCM

[0086]Paper plates coated with composition VIII are expected to have a long shelf life and to disintegrate a few days after being continuously exposed to moisture (e.g., the environment in a garbage dump).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com