All-protein implantable, resorbable reflectors

a reflector and all-protein technology, applied in the field of biophotonic and biomedical devices, can solve the problems of curbing image resolution and depth of observation, and imaging techniques are also limited by amount and type, and achieve the effect of slow degradability and no adverse biological effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Silk Fibroin Solution

[0136]Production of silk fibroin solutions has been described previously. Perry et al., 2008; McCarthy et al., 54 J. Biomed. Mats. Res. 139 (2001). Briefly, sericin, a water-soluble glycoprotein bound to raw fibroin filaments, was removed from the silk strands by boiling B. mori cocoons in a 0.02 M aqueous solution of NaCO3 for 60 min. Thereafter, the remaining silk fibroin bundle was rinsed thoroughly in purified water and allowed to dry overnight. The dry fibroin bundle was then dissolved in a 9.3 M aqueous solution of LiBr at 60° C. for 4 hr. The LiBr salt was then extracted from the solution over the course of three days, through a water-based dialysis process using Slide-A-Lyzer® 3.5K MWCO dialysis cassettes (Pierce, Rockford, Ill.). Any remaining particulates were removed through centrifugation and syringe-based micro-filtration (5 μm pore size, Millipore Inc., Bedford, Mass.). This process can yield 8%-10% (w / v) silk fibroin solution with m...

example 2

Fabrication of Silk Reflector Films

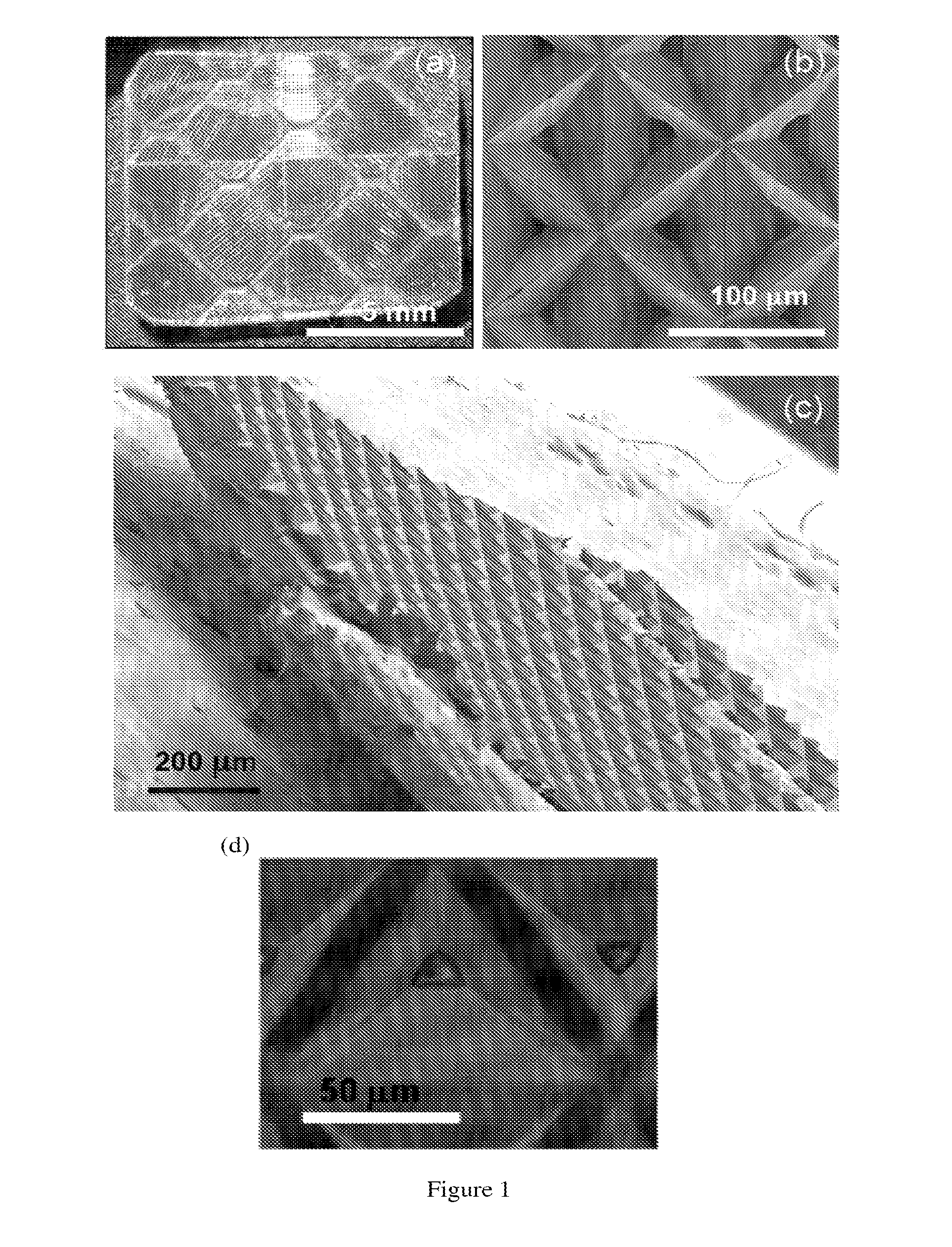

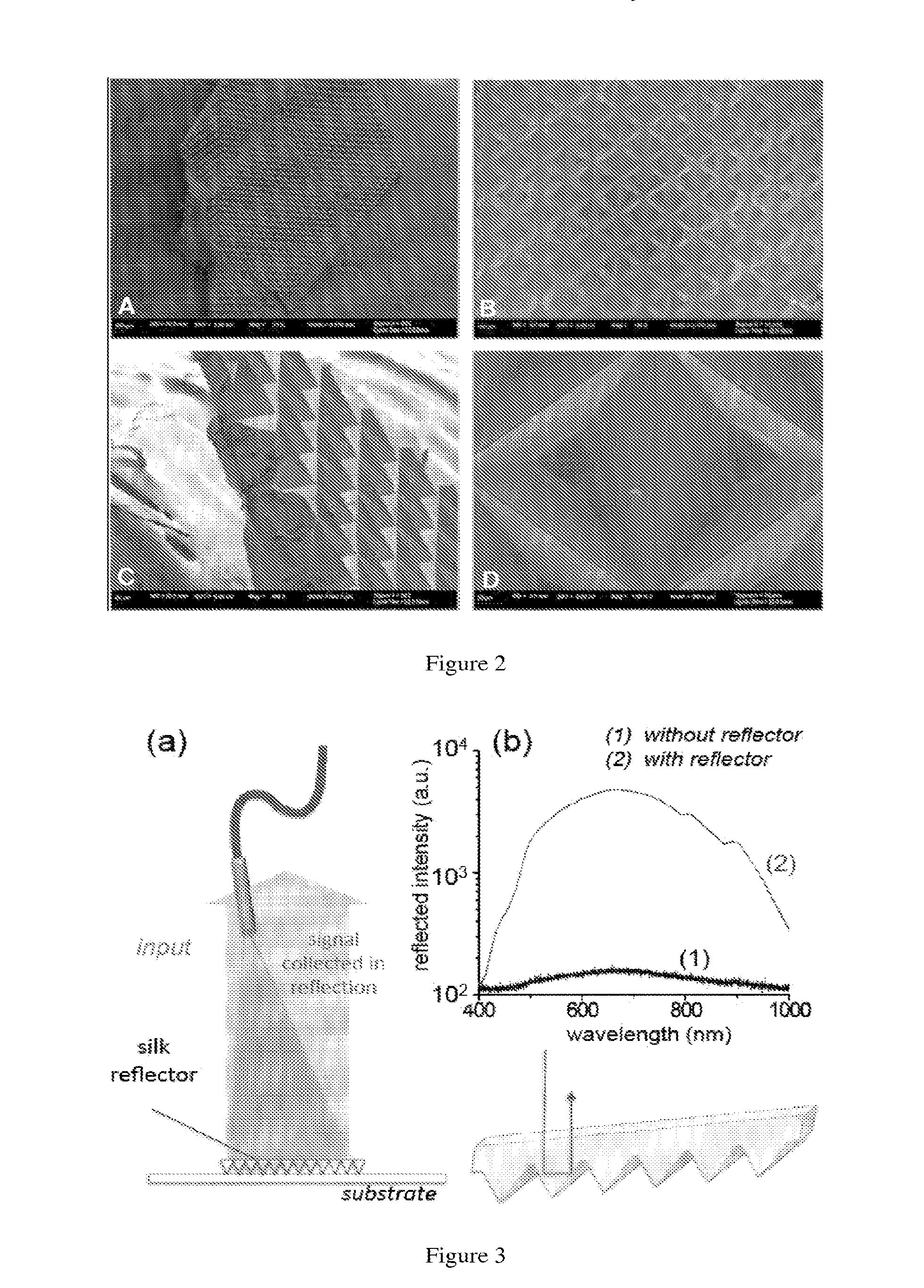

[0139]The fabrication of the silk reflector films was obtained by using a casting technique similar to soft-lithography. Perry et al., 2008; Xia & Whitesides, 1998. Briefly, silk fibroin solution of excellent optical quality and stability was cast onto a microprism master mould (3M™ SCOTCHLITE™ Reflective Material-High Gloss Film, 3M, St. Paul, Minn.). The master consists of an array of microprisms, which have dimensions of about 100 micrometers and clustered in groups as shown in FIG. 1 and FIG. 2.

[0140]The silk solution was allowed to dry and crystallize for 8-12 hours, upon which it was mechanically detached from the master surface. Upon microscopic examination, the silk retroreflective films replicate the master and have a reflective appearance similar to the master mould, as shown in FIG. 5. The index of refraction of silk is n=1.54. The silk films were water annealed to guarantee reduced solubility in a humid environment without loss of funct...

example 3

Reflection Measurements

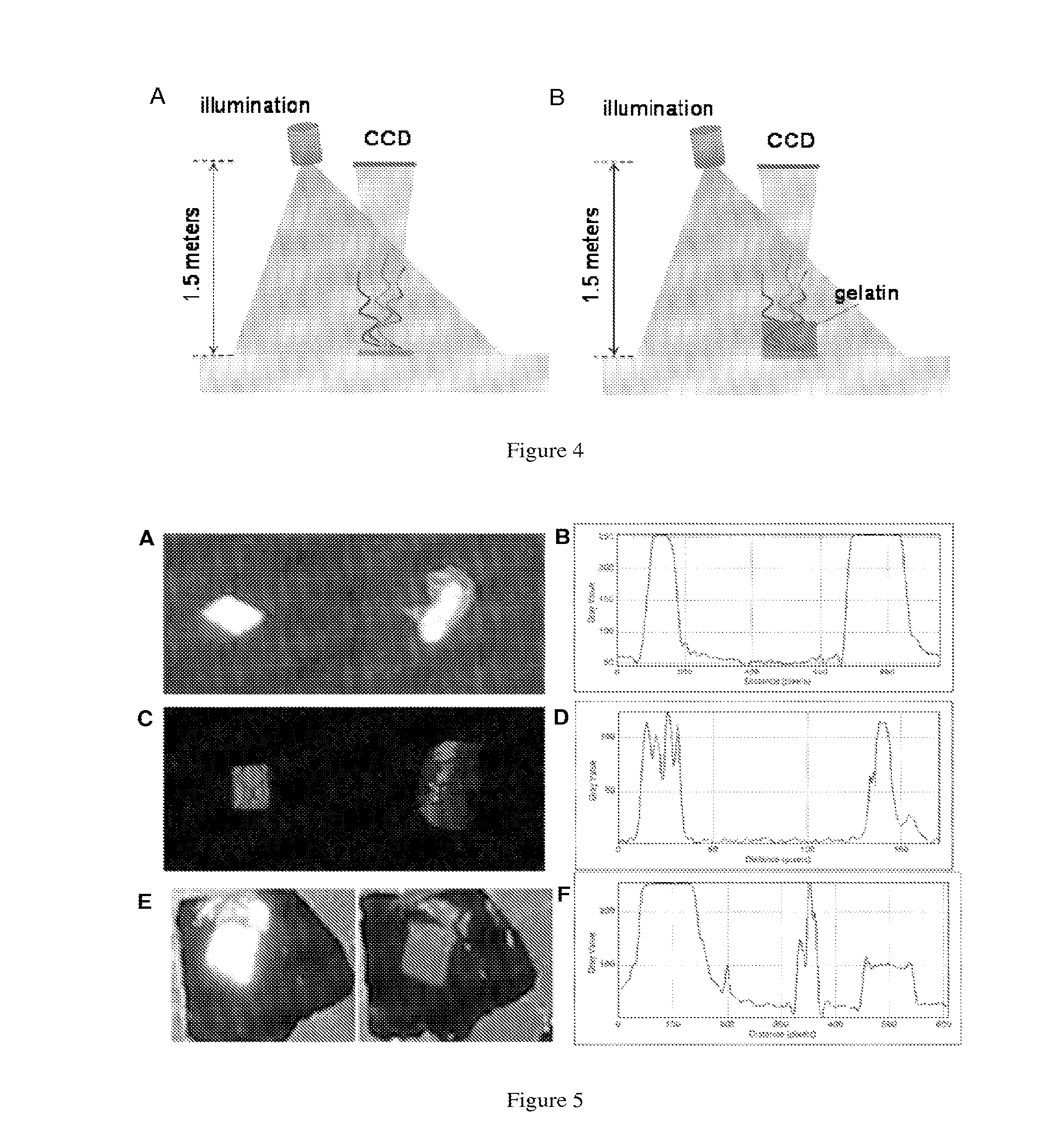

[0142]The retroreflecting silk film were characterized by measuring the luminous intensity and retroreflector coefficients per illuminance level on the surface of the retroreflector (in candelas / lx and candelas / (lx / m2), respectively).

[0143]The performance of the replicated silk films as reflectors was quantified by exposing the system to a quasi-isotropic illumination provided by a white light source (e.g., a flash light bulb). The reflection from the silk films was collected at a distance of 1.5 meters with a digital CCD camera, as shown in FIG. 3 and FIG. 7.

[0144]The experimental setup for measuring the increase in reflected signal is illustrated in FIG. 4 and FIG. 7. For example, in FIG. 7, the reflectivity measurements were performed by using a white light source. A red filter was applied to the white light source to reduce the spectral range, thus avoiding CCD saturation. The reflectivity was characterized for both the silk film replica and the master. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com