Solar fired combined cycle with supercritical turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

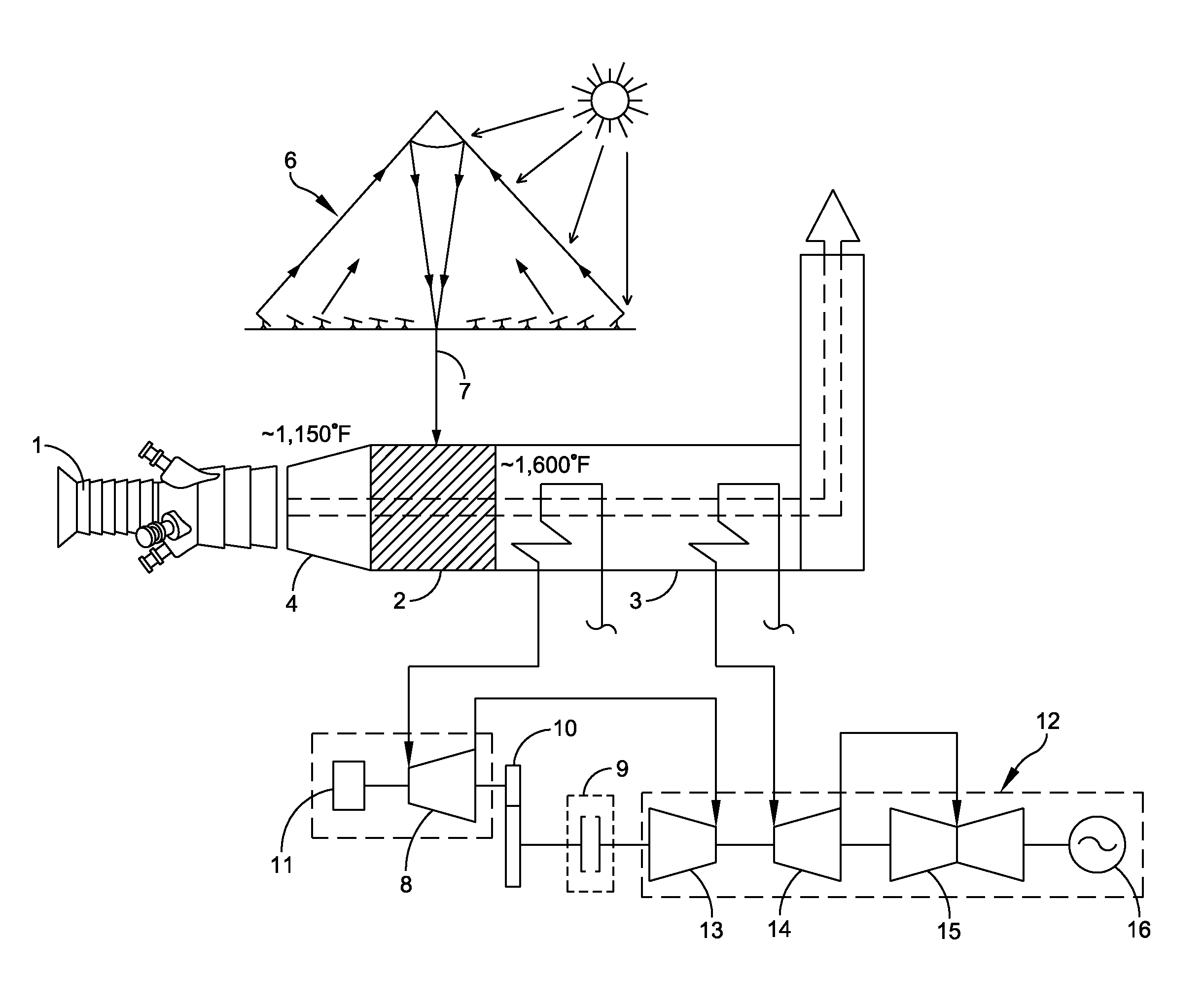

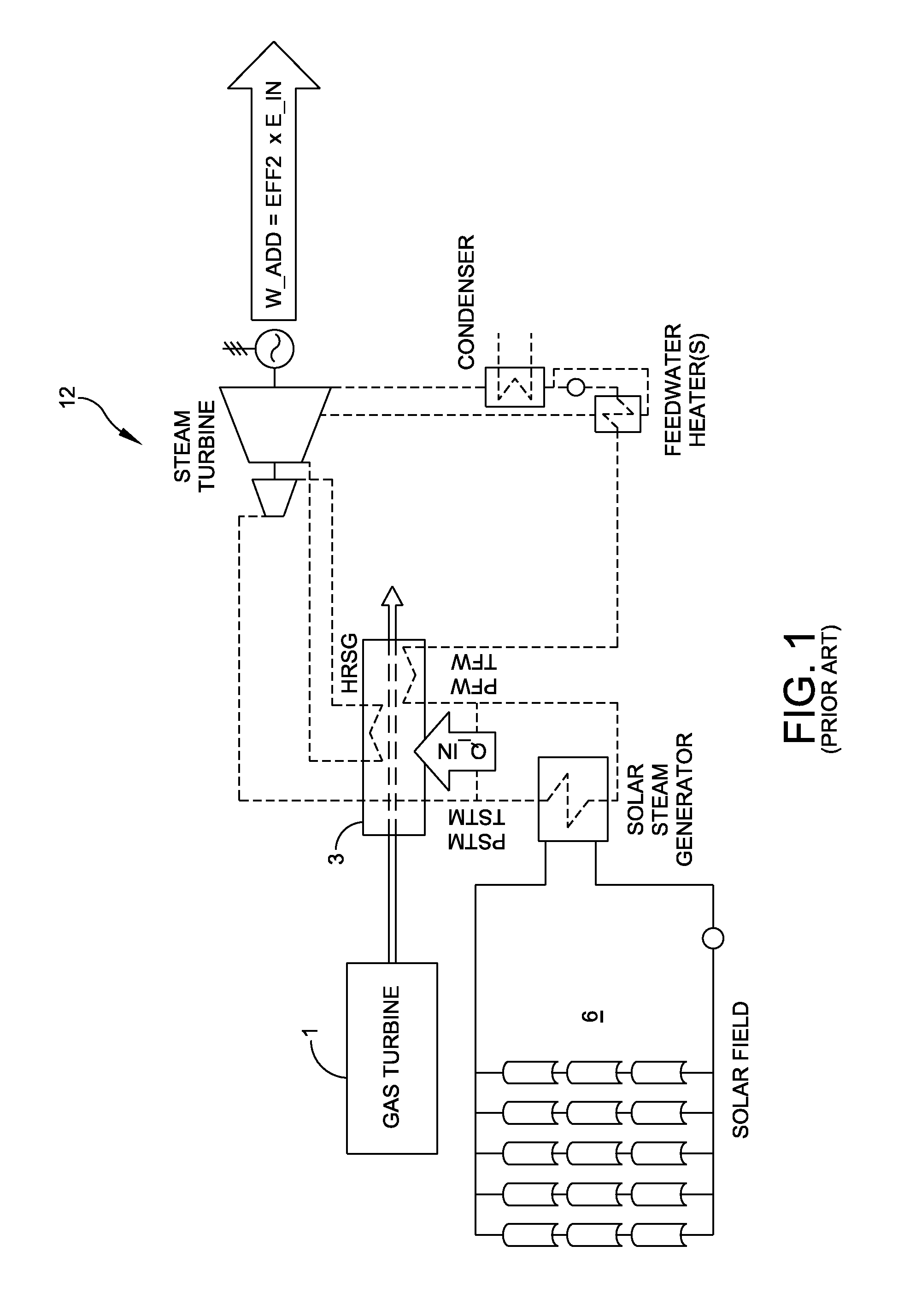

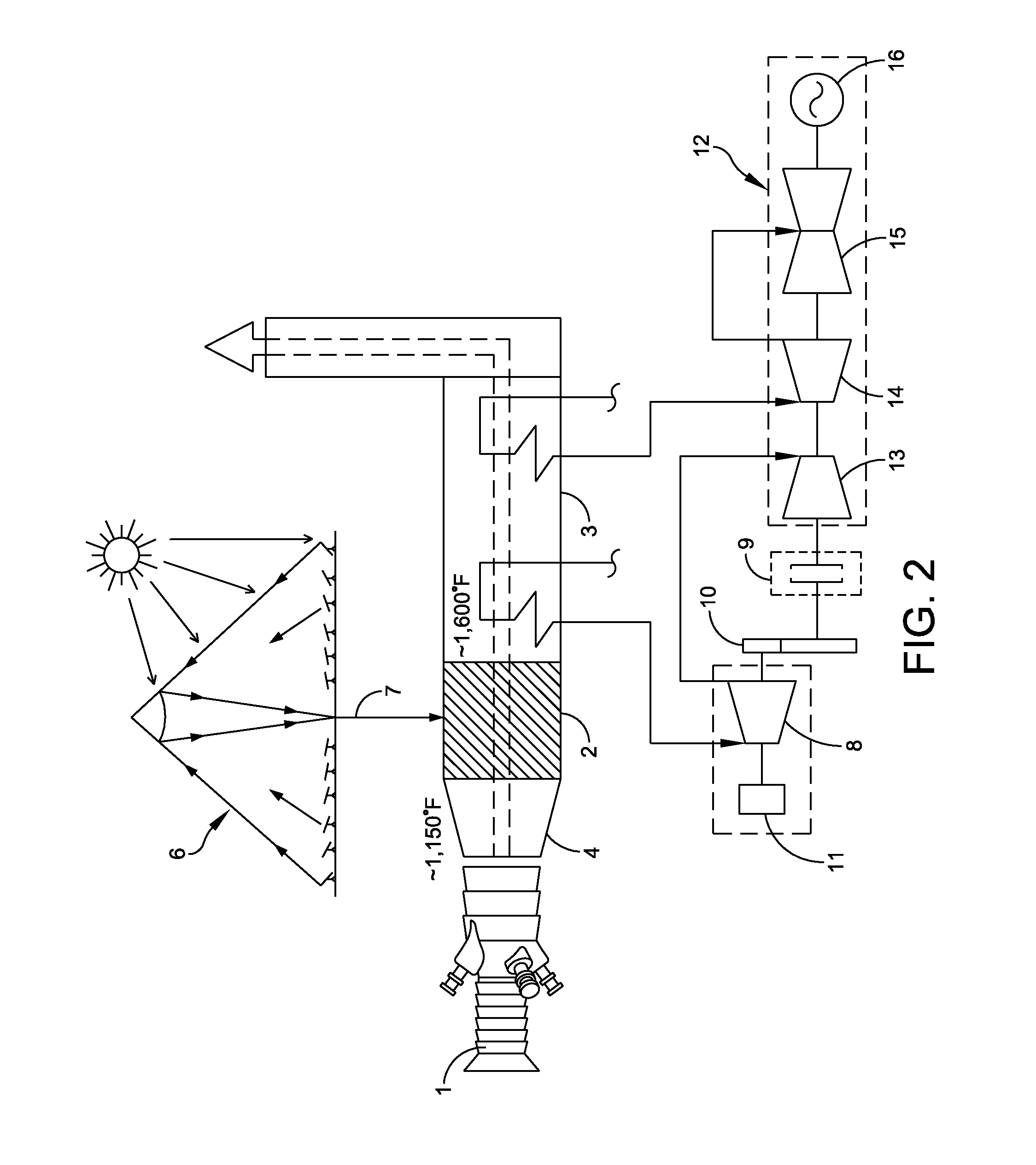

[0053]FIG. 1 shows the elements of a GTCC power plant having an associated solar power collection portion. Solar radiation is collected by multiple collector elements distributed over an area, so long as sunshine is present and incident on the collector elements. When solar radiation is present, it is used to heat a heat transfer medium used for extracting mechanical energy. Generally, the heat transfer medium produces or elevates the temperature of steam, through a heat exchanger. The flow of steam is passed through a steam turbine, resulting in a reduction in temperature or pressure (that is, enthalpy) in exchange for extracted mechanical energy. Typically the mechanical energy provides torque to a drive shaft coupled to an electric generator. In this disclosure, it should be appreciated that the term “coupled” denotes an operational connection of two or more elements wherein the connection may be direct or indirect, such as a connection through intervening elements.

[0054]For purp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com