Slim-line casing centralizer

a centralizer and slim-line technology, applied in the direction of drilling casings, drilling pipes, drilling rods, etc., can solve the problems of reducing the capacity requiring greater pumping. , to achieve the effect of reducing reducing the amount of side load support, and increasing the capacity of expansion and collaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

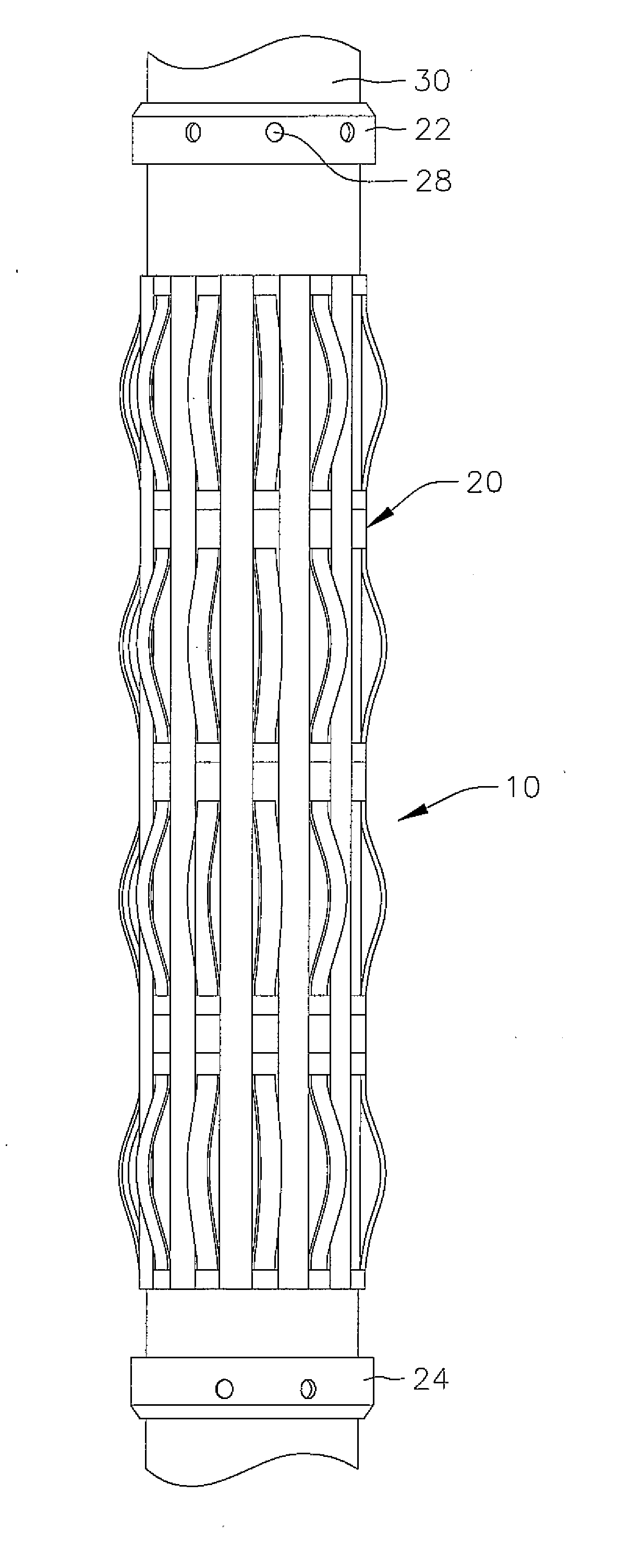

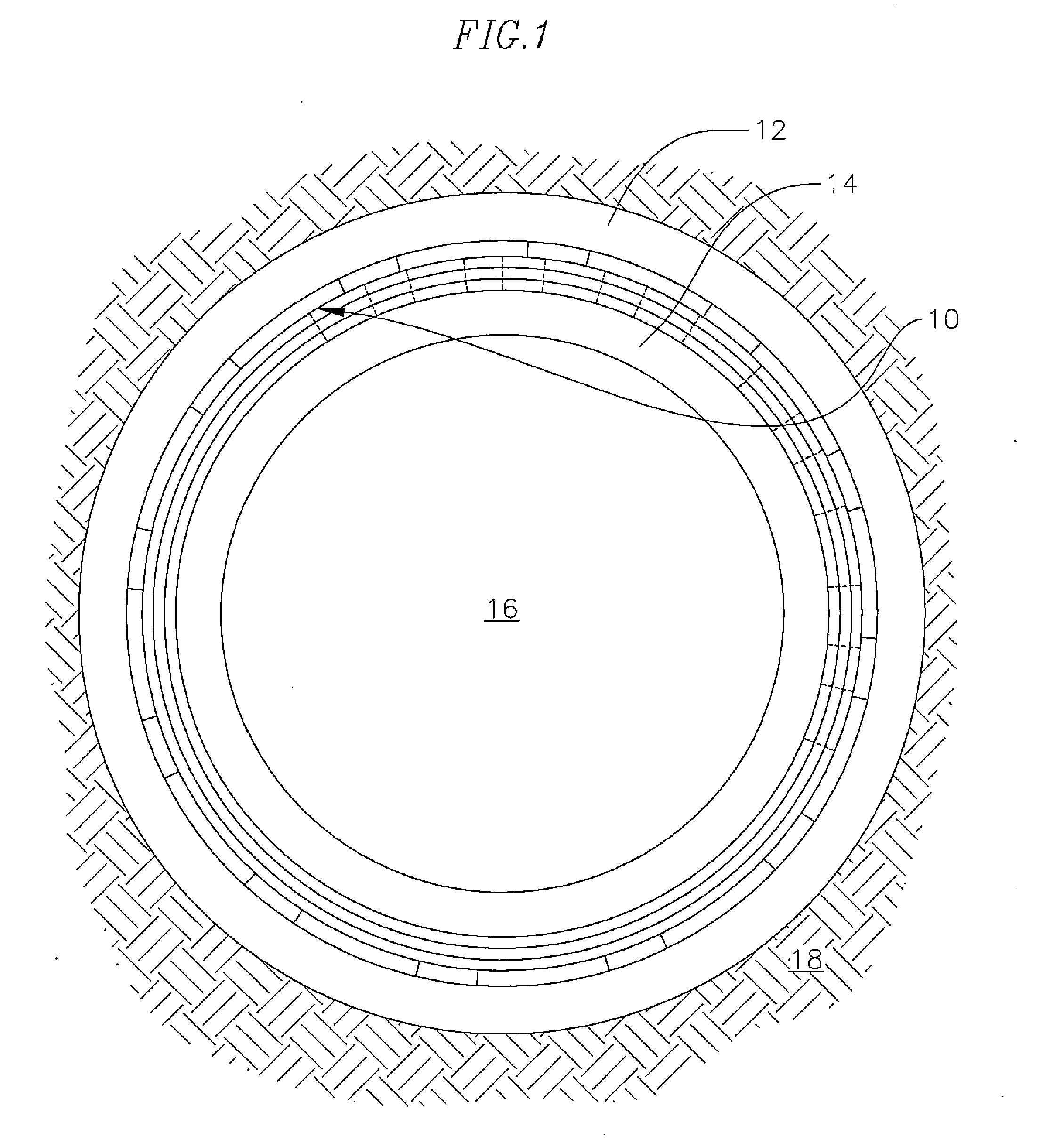

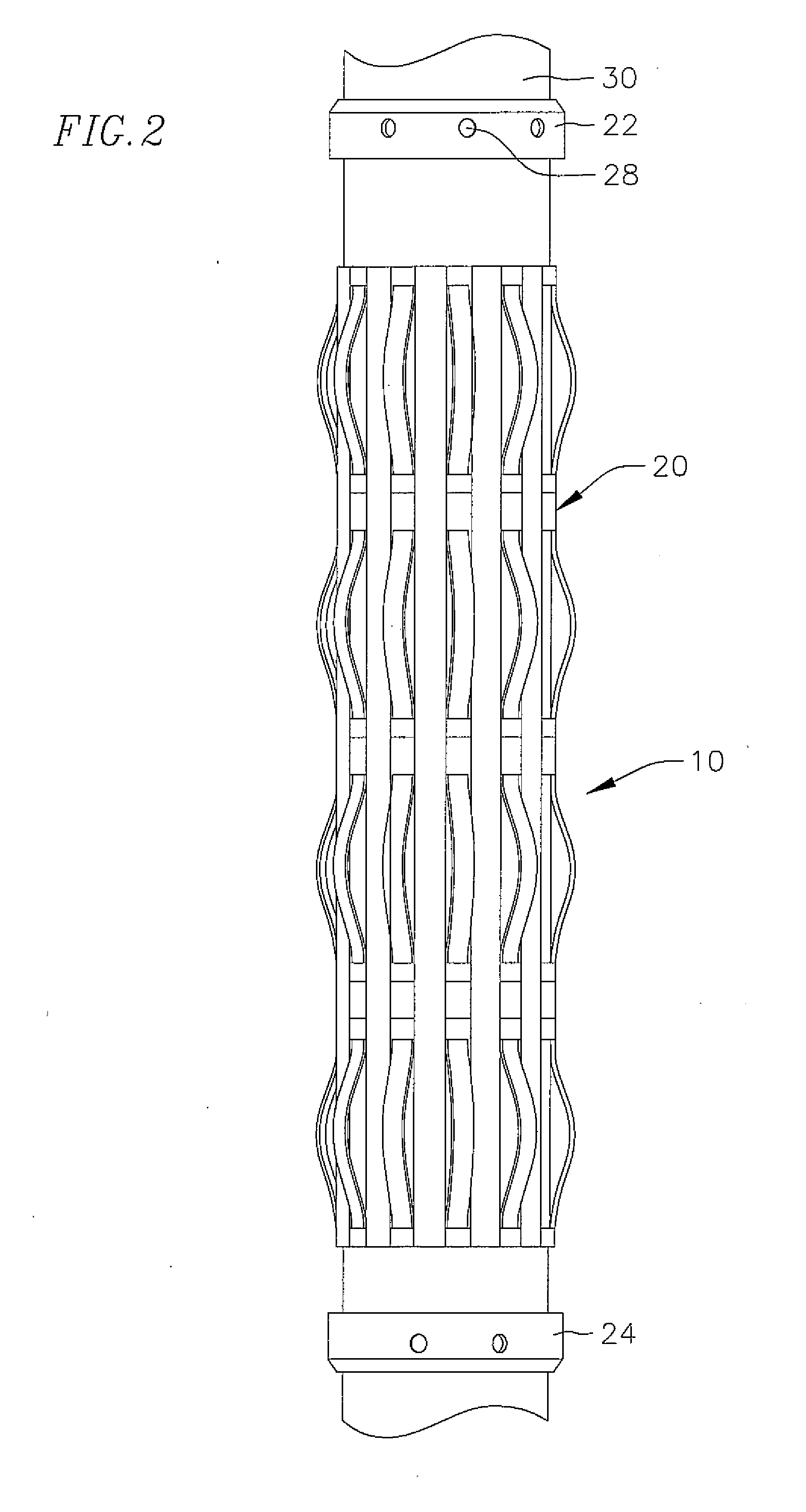

[0016]FIG. 1 is a cross sectional view of a slim-line casing centralizer 10 positioned in the narrow annular space between casings 12 and 14 located within a bore hole 16 drilled within an underground formation 18. As shown in FIG. 2, the casing centralizer 10 consists of a centralizer sleeve 20 and top and bottom stop collars 22 and 24. As also shown in FIG. 3, stop collars are typically made of steel or aluminum or other metal and include holes 26 for the insertion of steel set screws 28 which when turned apply a griping force from the collar to the inner casing 14.

[0017]As also can be seen in FIG. 4, the centralizer body or sleeve 20 is typically made of a sheet of steel that is quenched and tempered to produce a high strength spring-steel-like behavior. Alternatively, the centralizer body can be made of a low modulus high strength metal such as titanium or a specially designed fiber-epoxy composite.

[0018]The centralizer body can include a coating of low friction materials to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com