Electronic packaged device and manufacturing method thereof

a technology of electronic packaging and packaging layers, applied in the direction of electrical apparatus casings/cabinets/drawers, conductive pattern formation, earth/grounding circuits, etc., can solve the problems of increasing the difficulty of designing the electromagnetic shielding layer in electronic packaging, and the frequency of electromagnetic interference between different electronic components, so as to prevent electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

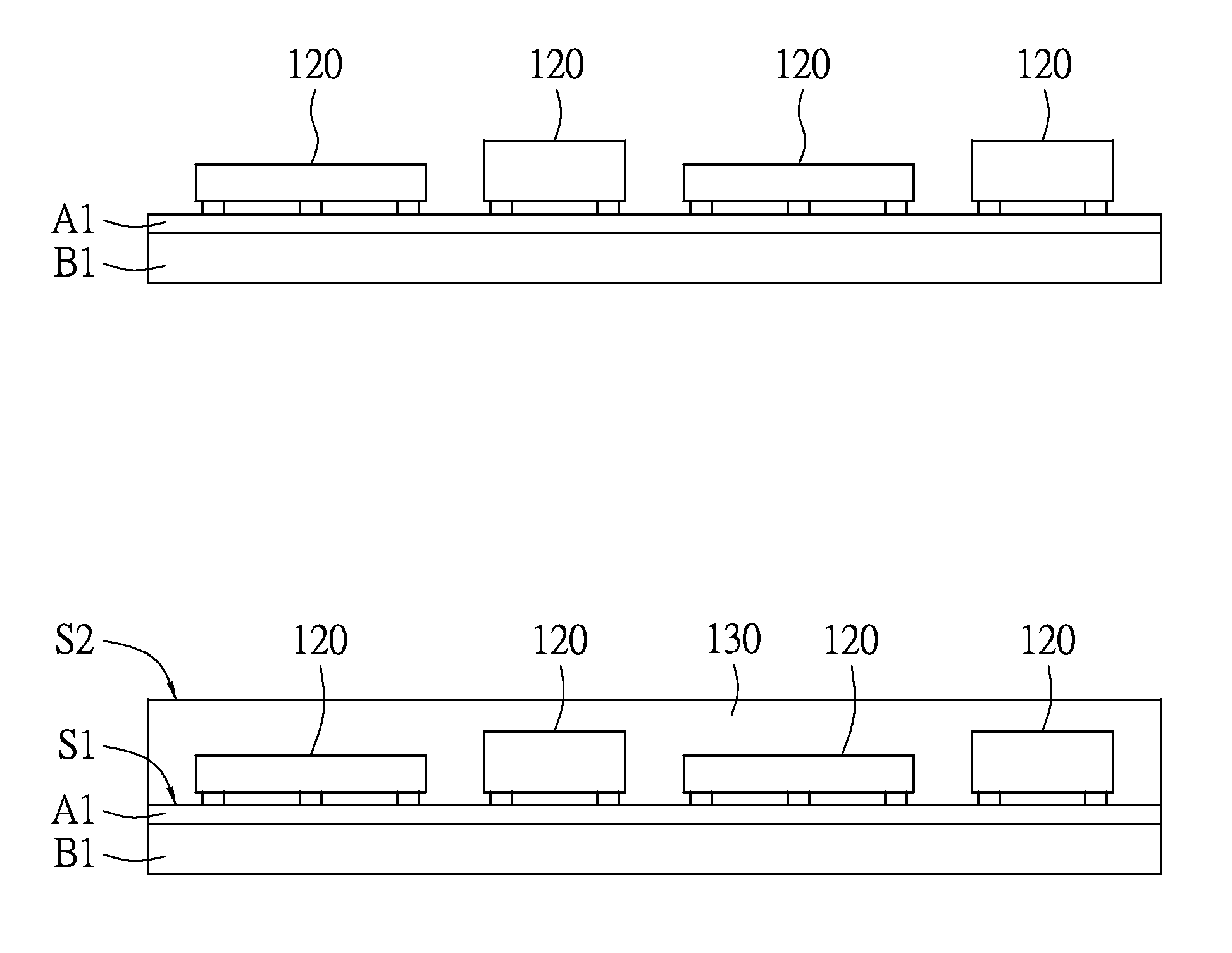

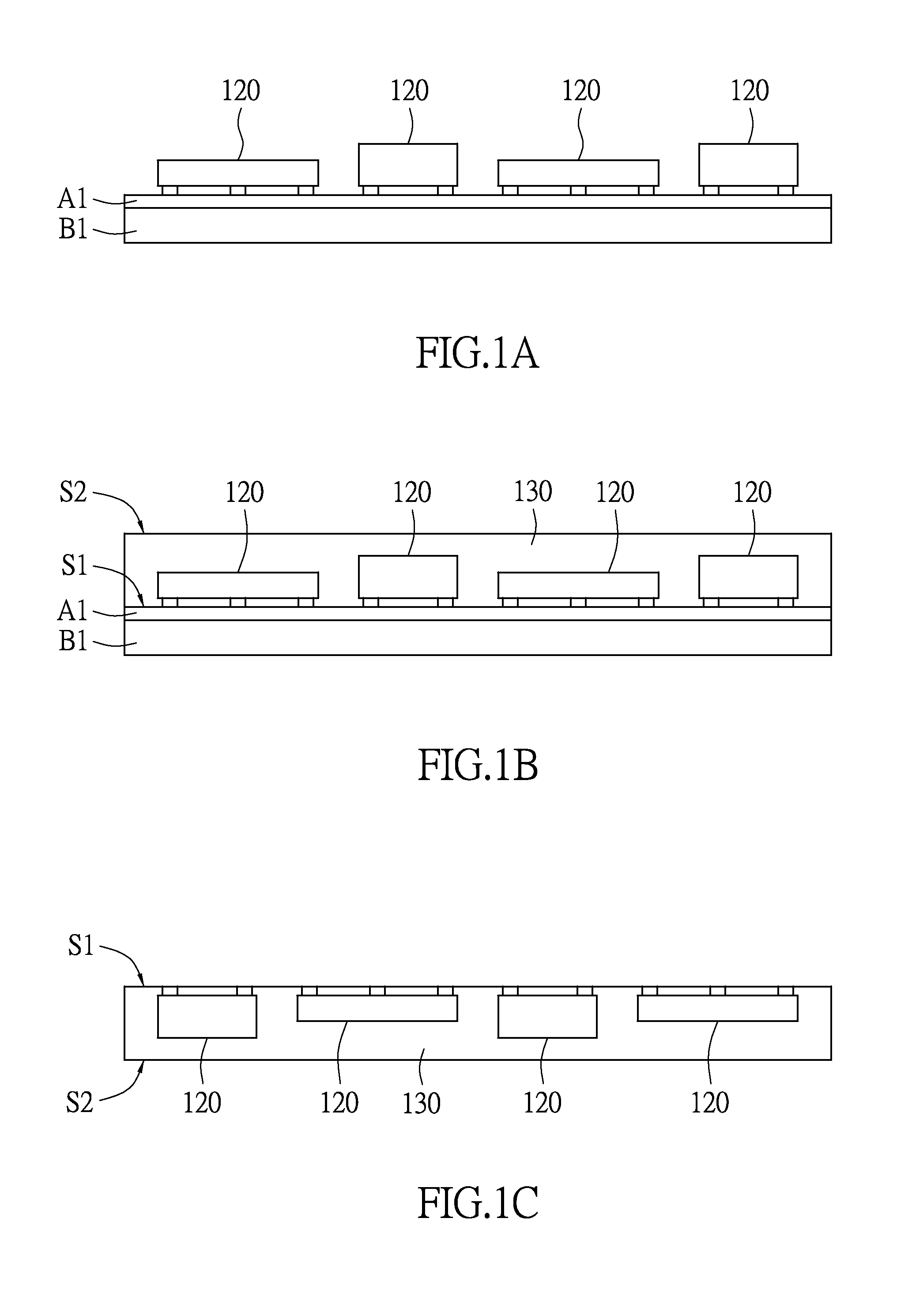

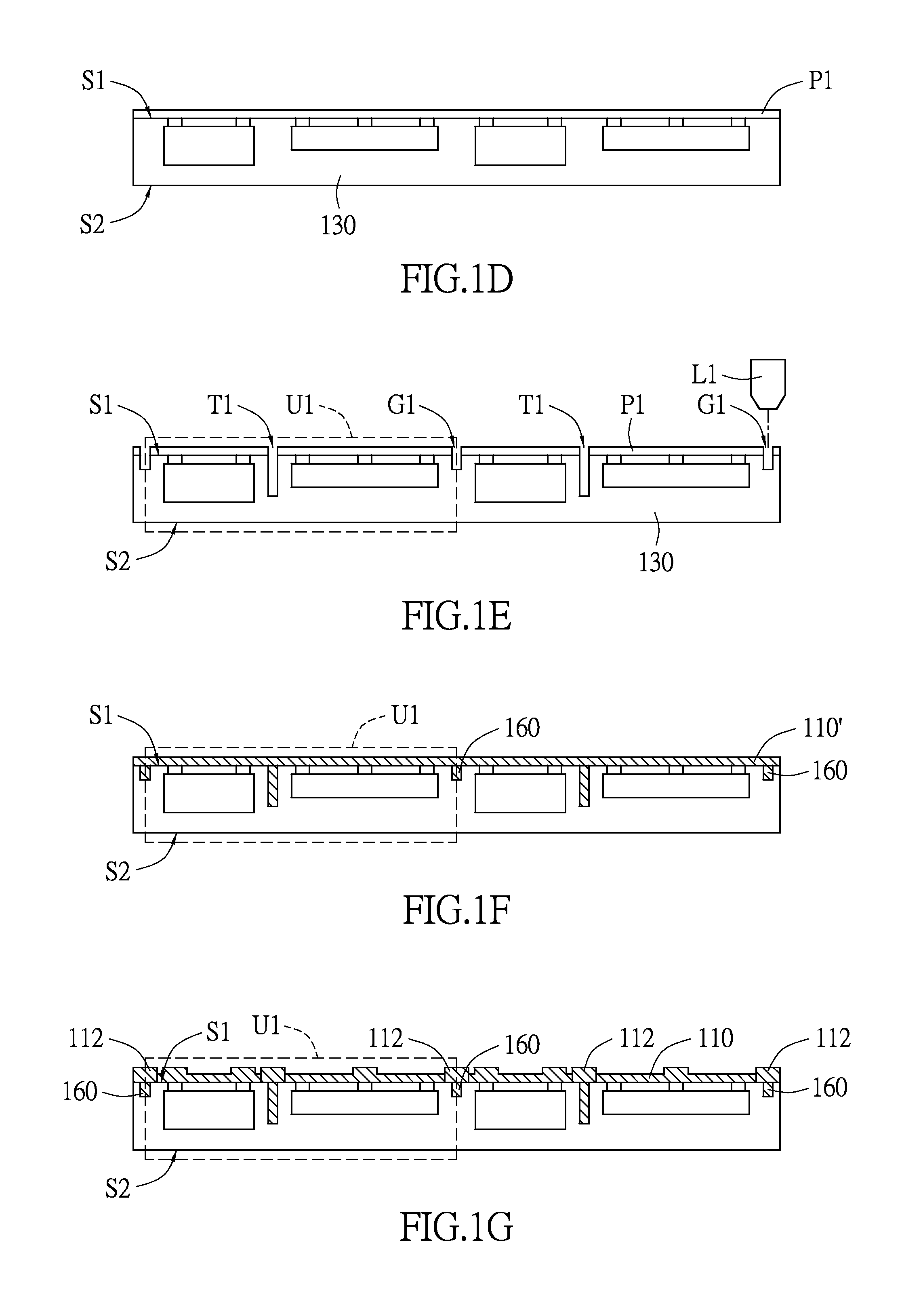

[0019]Please refer to FIGS. 1A to 1K as schematic diagrams illustrating steps of an electronic packaged device manufacturing method in accordance with the instant disclosure.

[0020]As shown in FIG. 1A, a plurality of electronic components 120 is configured on a surface of a substrate carrier B1. Adhesives A1 are applied onto the surface of the substrate carrier B1 to fix the electronic components 120 on the substrate carrier B1. Notably, the electronic components 120 can be chips, transistors, diodes, capacitors, inductors, or the like. The adhesives A1 can be glue, double sided tape, adhesive inks or the like. However, the coupling between the electronic components 120 and the substrate carrier B1 is not limited to the examples provided herein.

[0021]Please refer to FIG. 1B. An encapsulating member 130 is disposed on the surface of the substrate carrier to cover the electronic components 120. Typically, the encapsulating member 130 can be molding sealant or prepreg adhesives. The enc...

second embodiment

[0055]Please refer to FIG. 2C as schematic diagrams illustrating the structure of the electronic packaged device in accordance with the instant disclosure. The electronic packaged device 200 and the electronic packaged device 100 are similar, so the differences will be disclosed as follow.

[0056]In the instant embodiment, the shielding structure 240 is formed by spray coating, sputtering, printing, injection or the like to fill the trench F1 with conductive material. The shielding structure 240 extends from the first surface S1 (bottom surface) to the second surface S2 (top surface) of the encapsulating member 130 and is electrically connected to the electromagnetic shielding layer 150.

[0057]Moreover, the electromagnetic shielding layer 150 covers the second surface S2 of the encapsulating member 130 to electrically connect to the shielding structure 240, and the electromagnetic shielding layer 150 is physically and electrically connected to the grounding structure 260 at the sides o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

| electromagnetic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com