Polymerizable composition for stereolithography

a technology of polymerizable composition and stereolithography, which is applied in the direction of additive manufacturing apparatus, etc., can solve the problems of significantly low water solubility of radical polymerizable compound, achieve high water resistance, and easy to wash out with water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

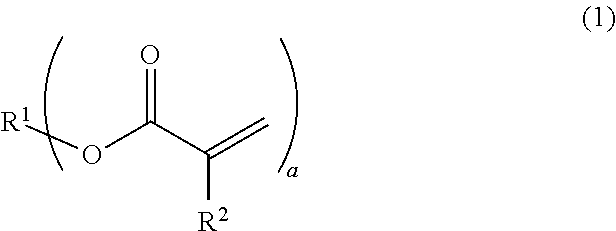

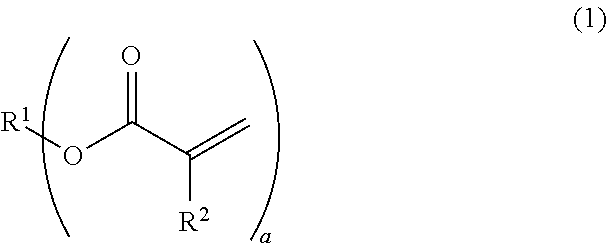

Method used

Image

Examples

example 1

[0064]As water-soluble radically polymerizable compound (A), NK Ester A-GLY-9E (trade name, Shin-Nakamura Chemical Co., Ltd., hereinafter, abbreviated as A-GLY-9E), as photopolymerization initiator (B), Lucirin TPO (trade name, BASF Japan Ltd., hereinafter, abbreviated as TPO) being 2,4,6-trimethylbenzoyl-diphenyl-phosphineoxide, and as ionic surfactant (C), NEOPELEX G-15 (trade name, Kao Corporation, hereinafter, abbreviated as G-15) being sodium dodecyl benzene sulfonate were mixed and dissolved with each other at a formulation described below, and then the resulting mixture was filtered with a membrane filter (5 μm) made of PTFE to prepare photopolymerizable composition 1.

(A) A-GLY-9E8.00g(B) TPO0.40g(C) G-150.084g

[0065]As a result of measuring a viscosity (at 25° C.) of photopolymerizable composition 1 using a cone-plate (E type) viscometer (TV-22, made by Toki Sangyo Co., Ltd., the same, hereinafter), the viscosity was 97 mPa·s.

example 2

[0066]Photopolymerizable composition 2 was prepared in a manner similar to Example 1 except that NK Ester A-GLY-20E (trade name, Shin-Nakamura Chemical Co., Ltd., hereinafter, abbreviated as A-GLY-20E) was used as water-soluble radically polymerizable compound (A) and a formulation ratio described below was applied.

(A) A-GLY-20E8.00g(B) TPO0.40g(C) G-150.084g

As a result of measuring a viscosity (at 25° C.) of photopolymerizable composition 2 using a cone-plate (E type) viscometer, the viscosity was 213 mPa·s.

example 3

[0067]Photopolymerizable composition 3 was prepared in a manner similar to Example 1 except that 4HBA (trade name, Nippon Kasei Chemical Co., Ltd., hereinafter, abbreviated as 4HBA) being 4-hydroxybutyl acrylate was used as water-soluble radically polymerizable compound (D) and a formulation ration described below was applied.

(A) A-GLY-20E5.00g(B) TPO0.40g(C) G-150.084g(D) 4HBA3.00g

As a result of measuring a viscosity (at 25° C.) of photopolymerizable composition 3 using a cone-plate (E type) viscometer, the viscosity was 28 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com