Method for Separating a Carbon Dioxide-rich Gas by Partial Condensation and Permeation

a carbon dioxide and gas technology, applied in gas treatment, lighting and heating apparatus, inorganic chemistry, etc., can solve the problems of complex recycling of fluids in exchangers, large temperature drop in the inlet gas of membranes and permeates, and degraded performance or even integrity, so as to reduce the flow area of permeates and optimize the system , the volume flow rate of gas is very high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

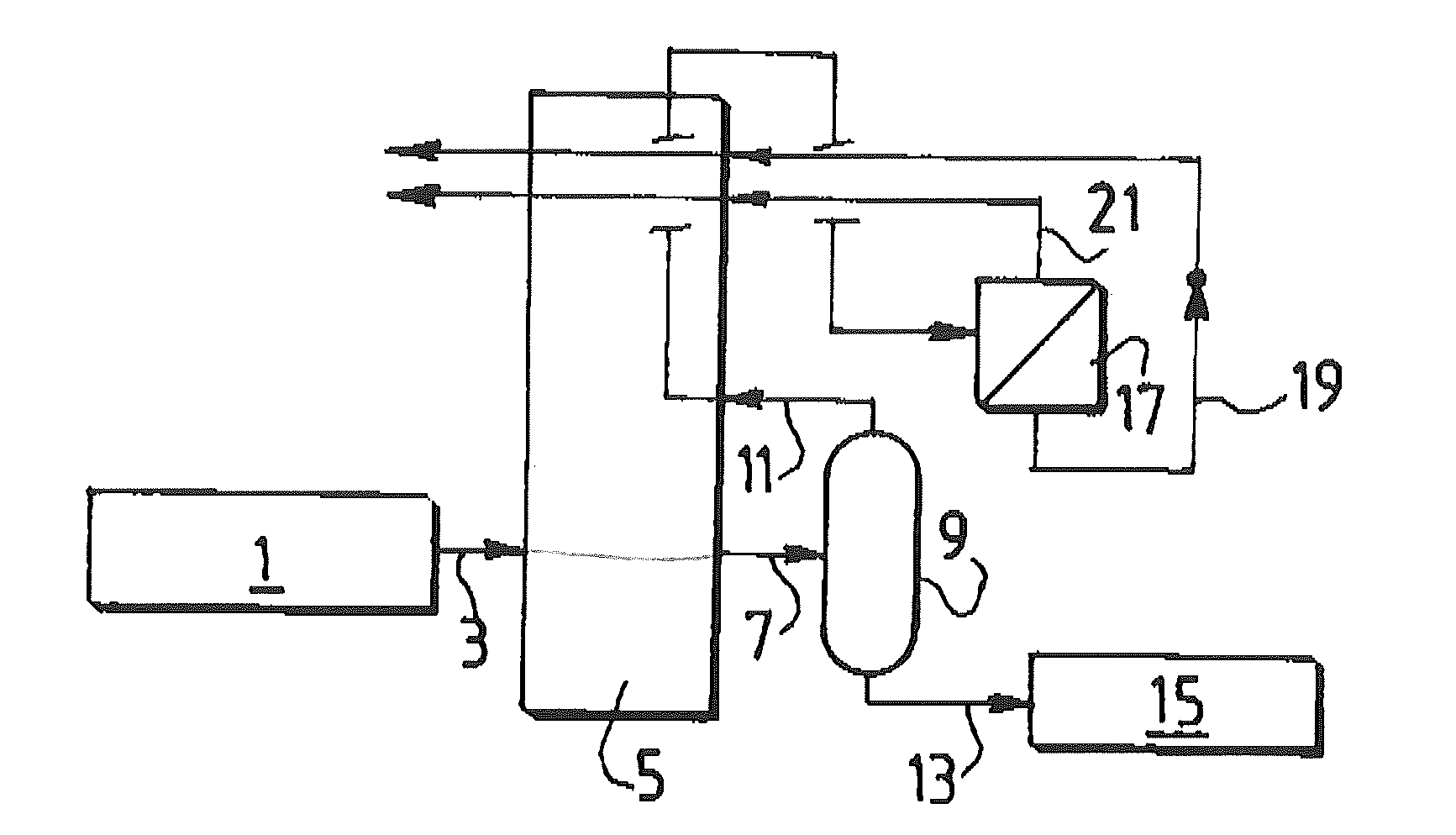

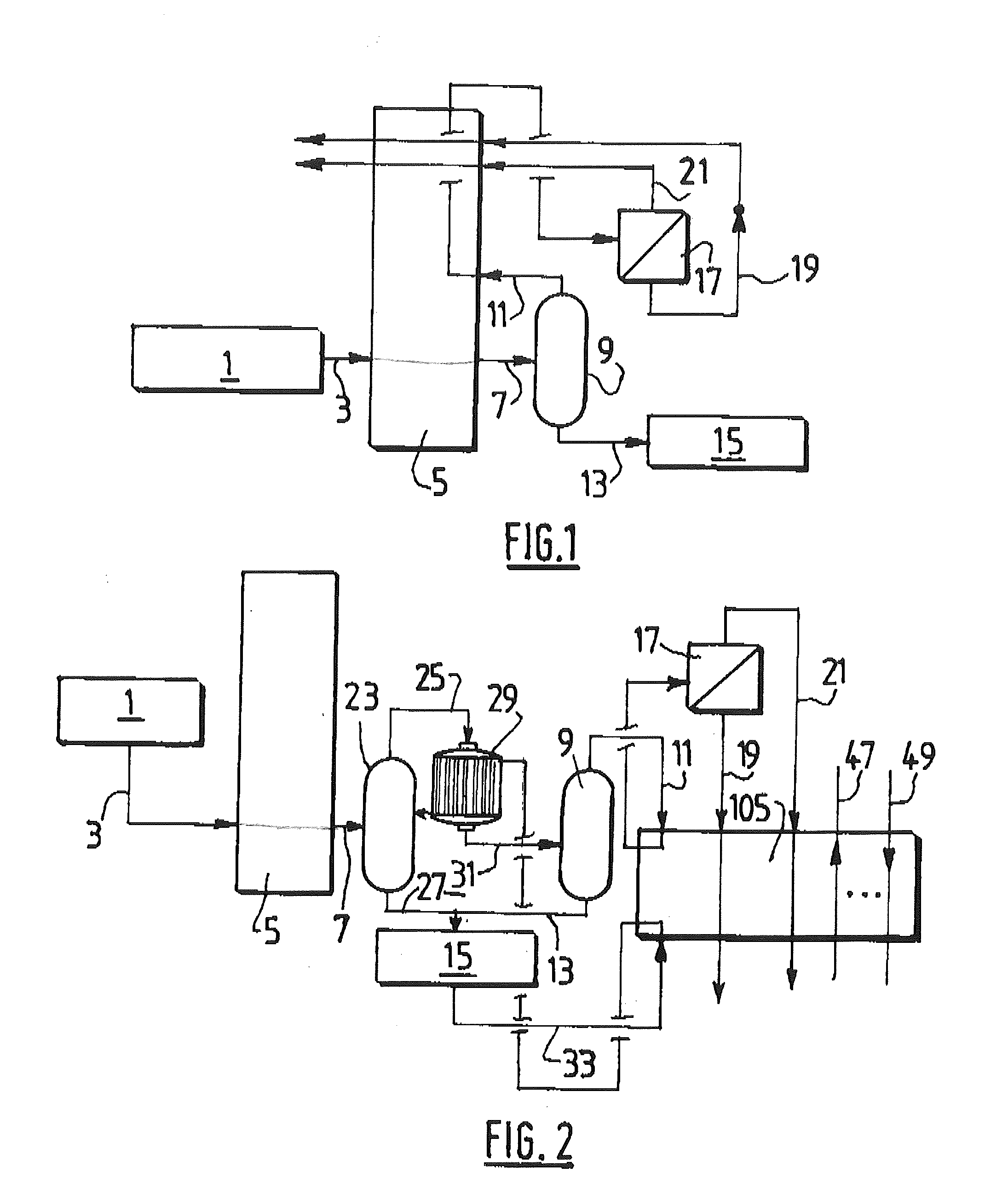

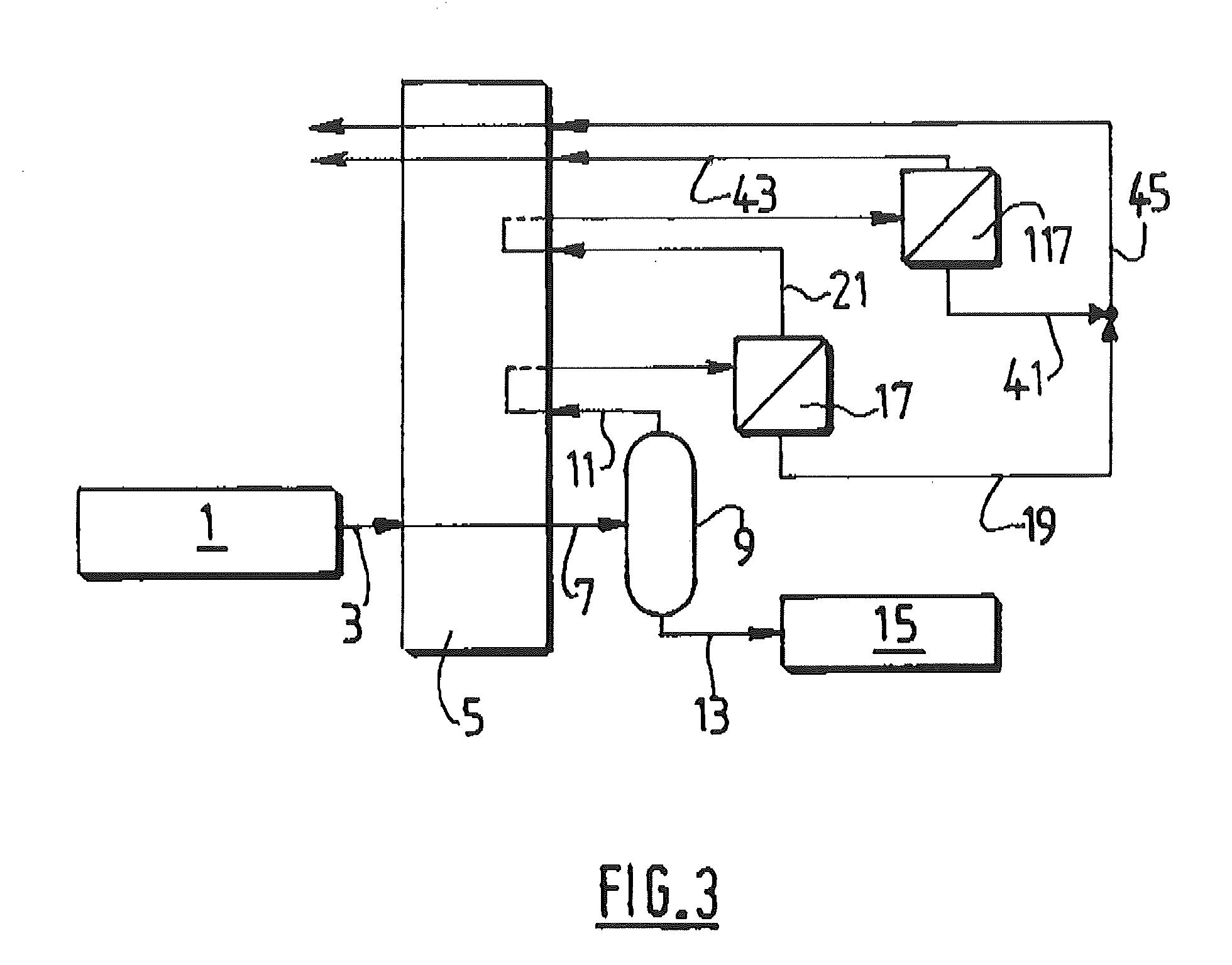

[0041]The invention will be described in greater detail by referring to the figures. FIGS. 1 to 3 represent processes according to the invention.

[0042]In FIG. 1, an oxy-fuel combustion unit 1 produces a gas stream 3 rich in carbon dioxide that contains at least 80% carbon dioxide on a dry basis, and also at least oxygen, nitrogen and argon. The gas is cooled in a first heat exchanger 5 which is a brazed aluminum plate-fin exchanger. The cooled gas 7 at a temperature between −50° C. and −53° C. is sent to a phase separator 9 which produces a gas 11 enriched in oxygen, nitrogen and argon that contains 34% carbon dioxide and a liquid 13 enriched in carbon dioxide. The liquid 13 is sent to a storage vessel 15 as final product. The gas 11 is warmed in the first exchanger 5 to between −35° C. and −45° C., for example −40° C. and then sent to a permeation separation stage 17. This permeation causes a cooling of the products. The permeate 19 at −42° C. is expanded and then sent to be warmed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com