DEVICES AND METHODS FOR CONTROLLlNG MAGNETIC ANISTROPY WITH LOCALIZED BIAXIAL STRAIN IN A PIEZOELECTRIC SUBSTRATE

a piezoelectric substrate and localized biaxial strain technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, digital storage, instruments, etc., can solve problems such as film strain modifying the magnetic properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055]To further demonstrate the operational principles of the devices and methods, finite element simulations (FEA) were used to design nanoarchitectured devices that were fabricated and used to demonstrate highly localized voltage controlled manipulation of an engineered magnetic domain structure in a Ni ring. The layer thicknesses of the figures do not reflect scale. A schematic diagram of a device structure that can create magnetoelastic anisotropy on magnetic elements (a ring is shown as an example) in three directions by applying voltage on three pairs of electrodes is shown in FIG. 4A and sequential actuation of the paired electrodes is shown in FIG. 4B through FIG. 4D.

[0056]The structure consists of a Si wafer substrate 68, a bottom electrode 66, a PZT thin film 64, and, in this case, three pairs of electrodes surrounding a middle magnetic element. The electrode 70 is paired with electrode 72 and is designated (A-A). Electrode 74 is paired with electrode 76 (B-B) and electro...

example 2

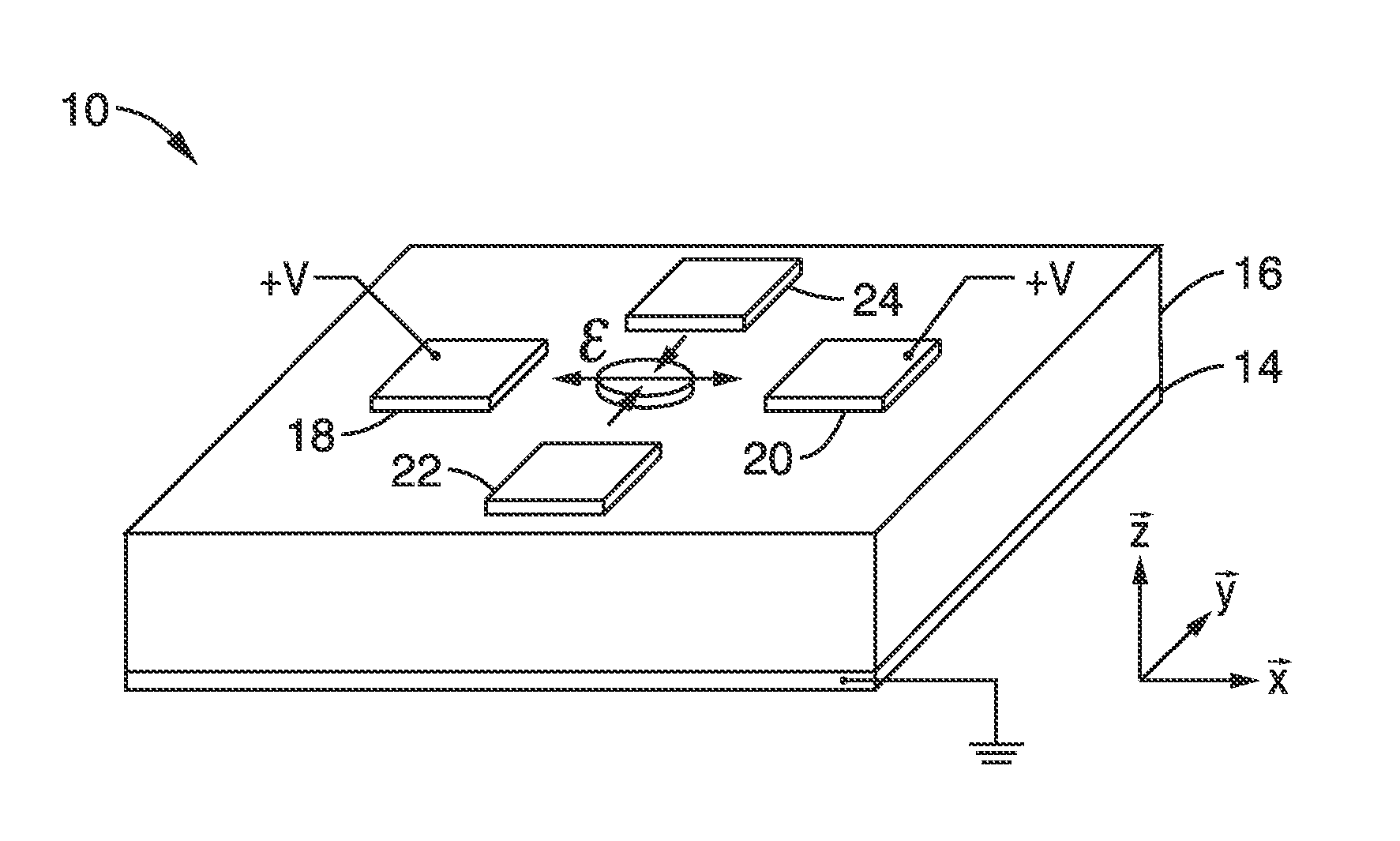

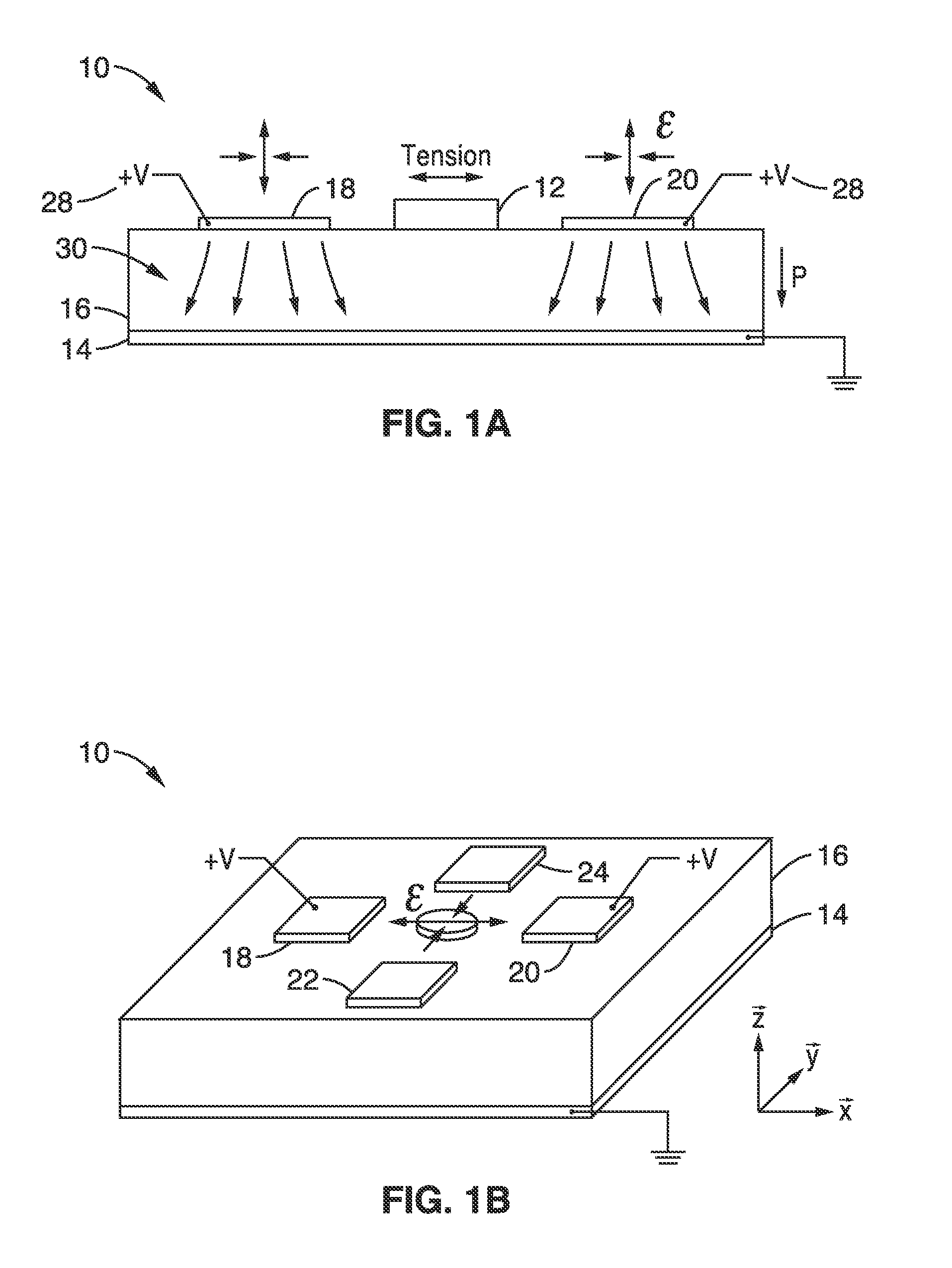

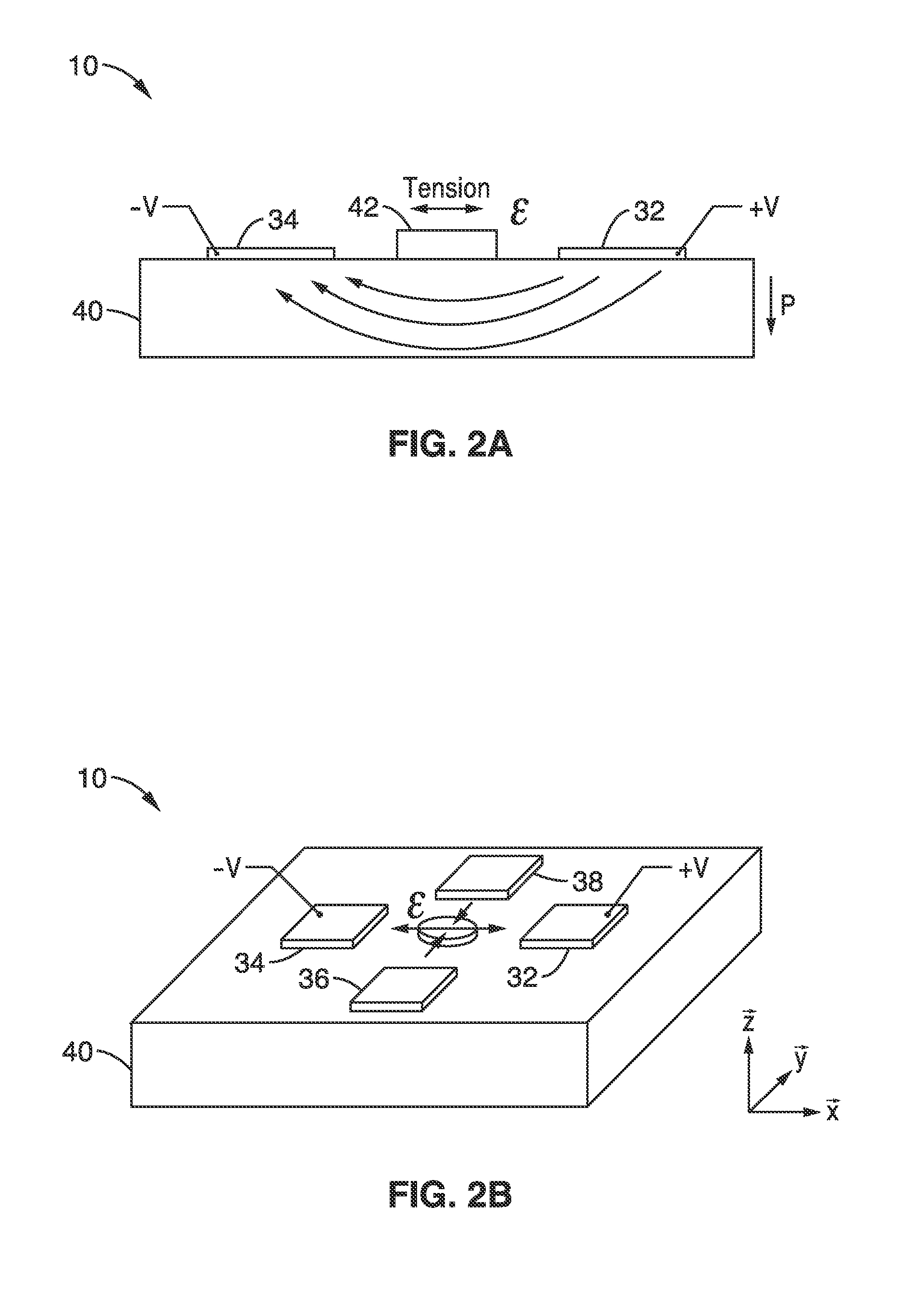

[0065]In order to demonstrate the technology, an analytical model of a device with the structure shown in FIG. 1A and FIG. 1B was constructed to demonstrate the reorientation of the magnetization of a magnetostrictive ellipse, a configuration that could represent a memory bit or a component of a memory bit that could be part of an array of bits. The memory bit included an elliptical ferromagnetic element deposited on a ferroelectric layer with four patterned electrodes around the ferromagnetic element. All four boundaries of the PZT thin film were clamped by a Si substrate.

[0066]Specifically, the structure had a 500 nm piezoelectric transducer (PZT)-5H thin film with a Pt bottom ground electrode deposited onto a 0.5 mm thick Si substrate. A 150 nm×120 nm×10 nm Ni ellipse was surrounded by four 125 nm×125 nm×10 nm Au electrodes in this example. The two electrodes A-A were at a 45° angle, and the two electrodes B-B were at a 135° angle relative to the major axis of the ellipse (i.e., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com