Variable diameter radial uniform uncoupling continuous charging structure and charging method thereof

A technology of variable diameter and charge, which is applied in blasting and other directions, can solve the problems of reduced stability of surrounding rock, increased existence time of blasting gas, and hole wall damage, so as to overcome rock mass sandwiching effect, improve effective utilization rate, The effect of reducing the difficulty of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

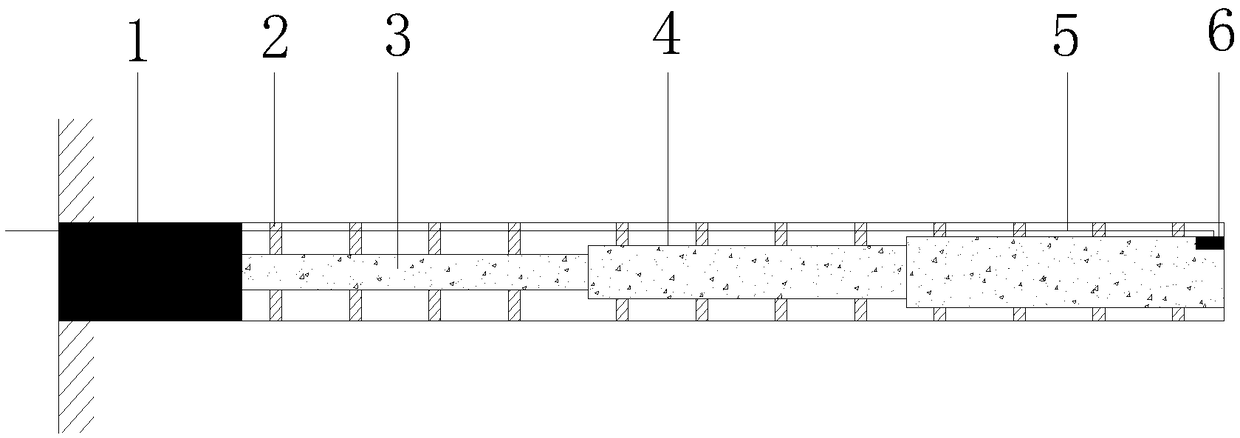

[0036] For the charging method of variable diameter radial uniform non-coupling continuous charging structure, the specific steps are as follows:

[0037] 1) Drill a peripheral hole with a diameter of D and a depth of L along the excavation contour, and determine the charge length L according to the rock and terrain conditions 1 and the plugging length L 2 ;

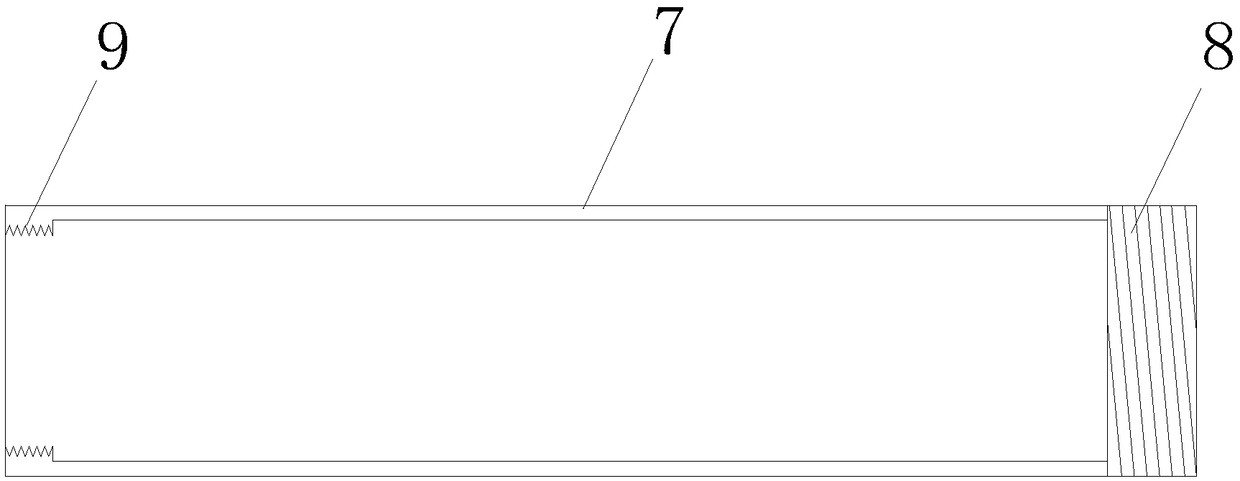

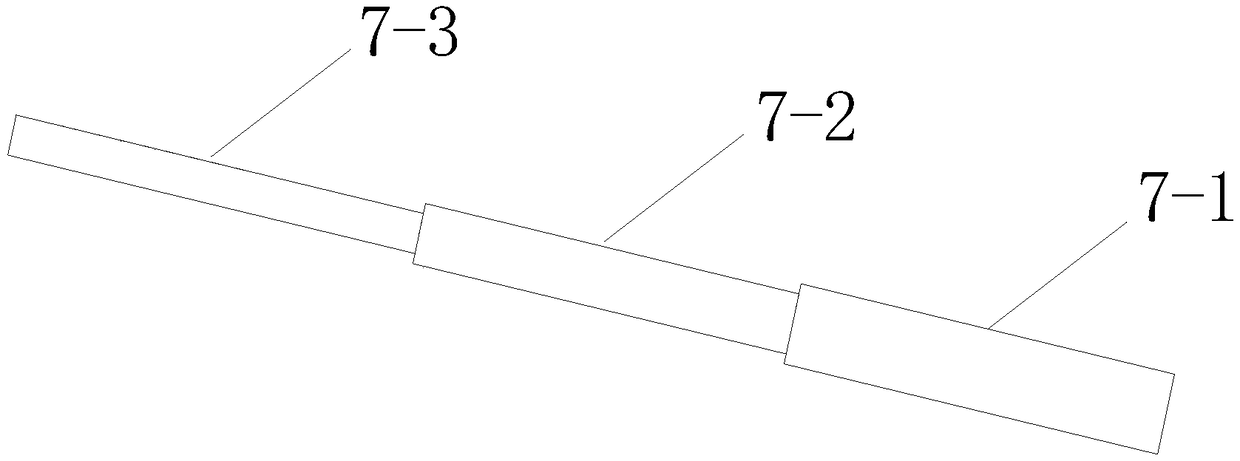

[0038] 2) According to the sequence from the bottom of the hole to the orifice, the ratio of diameter is 1.2:1:0.8, and the ratio of length is 1:1:1, select three sections of PVC pipe 7, which are No. 1 PVC pipe 7-1 and No. 2 PVC pipe The outer diameters of No. 7-2 and No. 3 PVC pipes 7-3, No. 1 PVC pipe 7-1, No. 2 PVC pipe 7-2 and No. 3 PVC pipe 7-3 are reduced in proportion to D respectively. 1 、D 2 、D 3 , the total length is equal to the design charge length L 1 ;

[0039] 3) According to the outer diameter D of No. 1 PVC pipe 7-1, No. 2 PVC pipe 7-2 and No. 3 PVC pipe 7-3 1 、D 2 、D 3 , choose the inner diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com