Apparatus and method for oxidative treatment of organic contaminants in waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

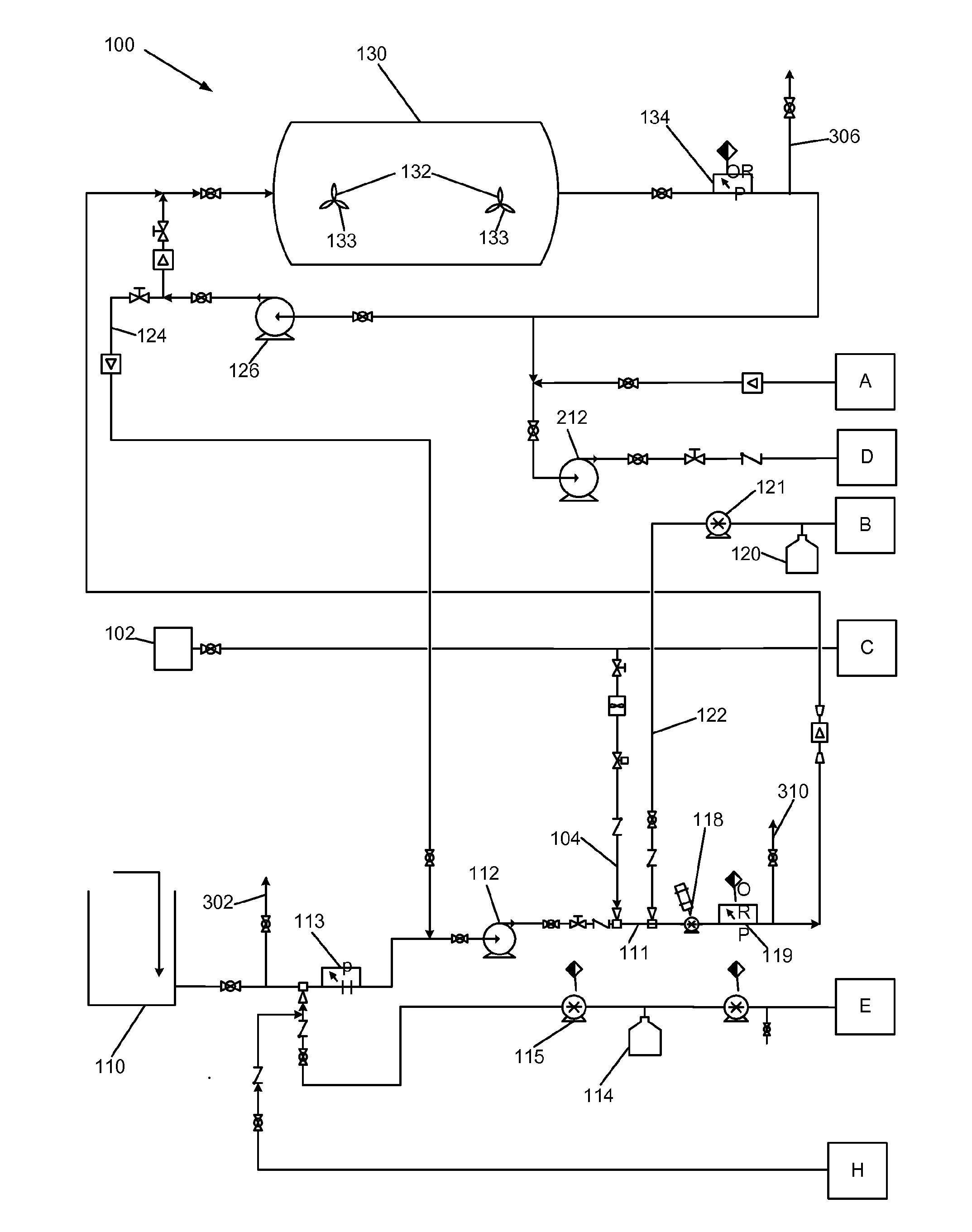

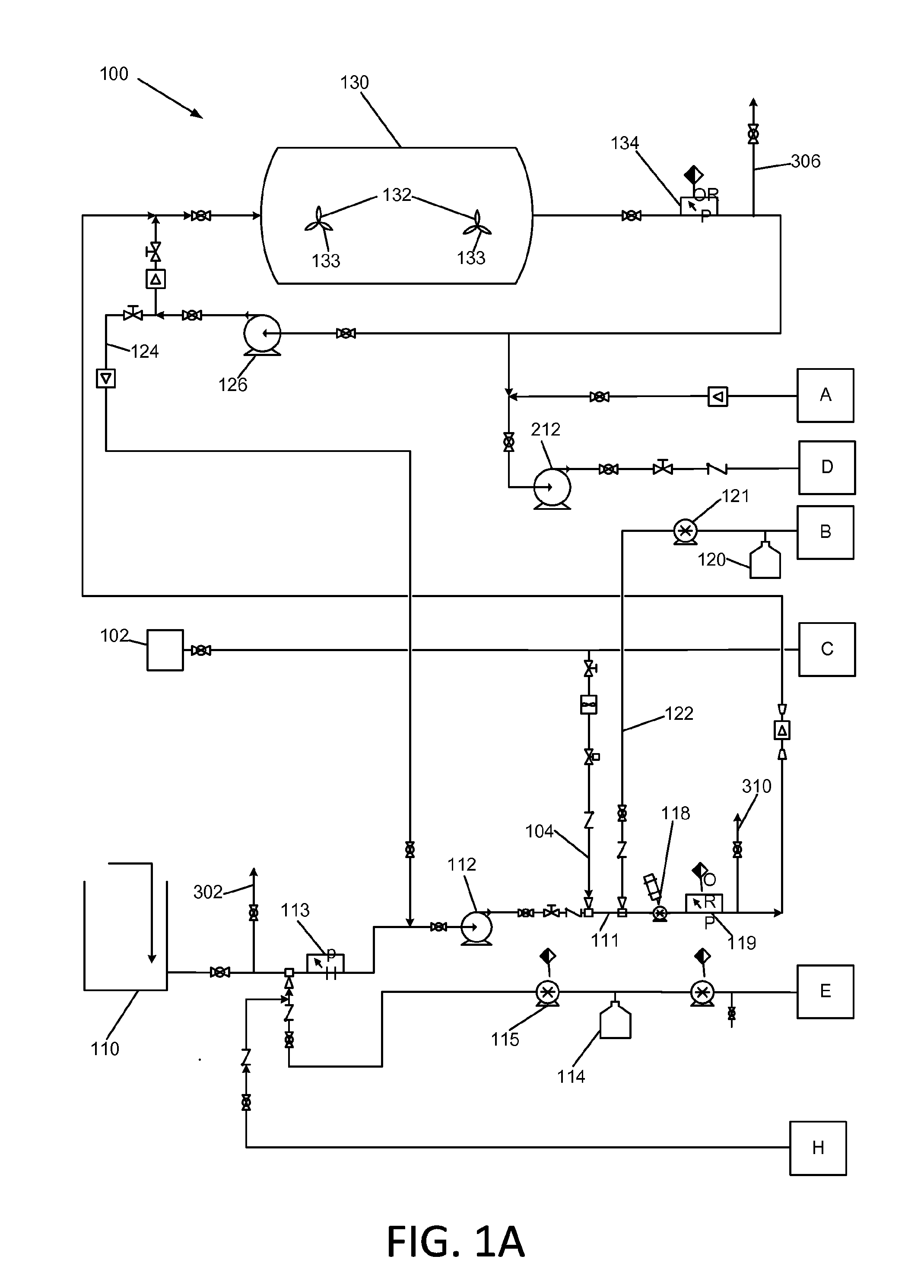

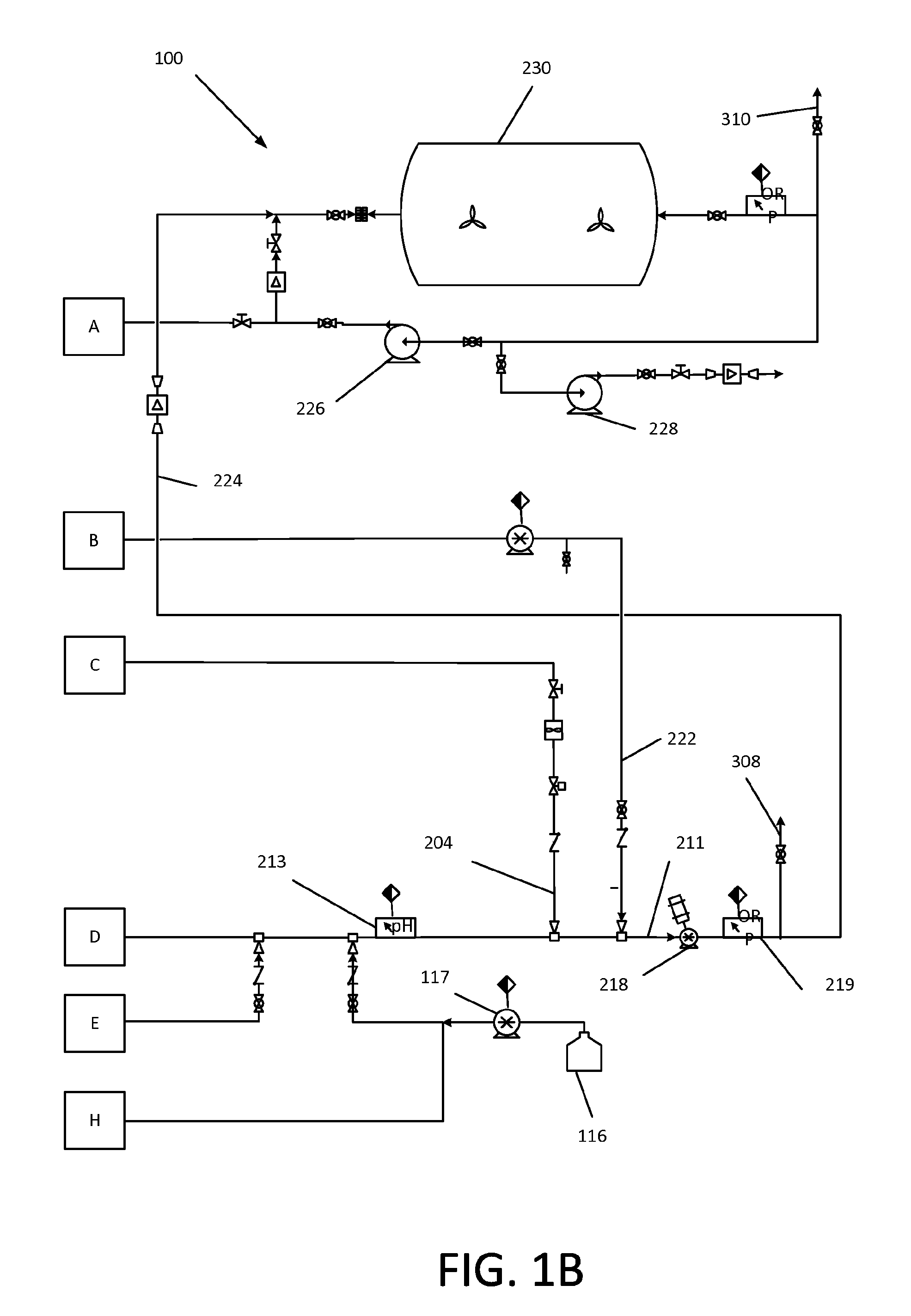

Image

Examples

example

[0048]The following example of operation of the Applicants apparatus and advanced oxidation waste water treatment method is to be considered exemplary and not limiting.

[0049]In an experimental trial, waste water was recovered from a hydraulically fractured oil or gas well. (This waste water is also known in the industry as “flowback water.”) In the experimental trial, optimization of oxidation of the organic contaminants in the waste water was desired. The Applicants have found that not all of the organic matter can always be reduced, in which case separate chemical treatment is indicated. However the economically optimized level considered for this process is for treatment to the maximum level achievable with ozone and hydrogen peroxide alone within two to four hours of retention time. The process allows for longer treatment times if desired by the operator.

[0050]The following chemical relationships were discovered in performing the experimental trial:[0051]When treating fracking f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com