Piezo Electric and High Voltage Absorption Cooling System

a cooling system and high-voltage technology, applied in the field of absorption cooling systems, can solve the problems of increasing electrical energy demand, limited use cases of mainstream absorption air conditioners, and regional blackouts, and achieve the effect of removing these harmful environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

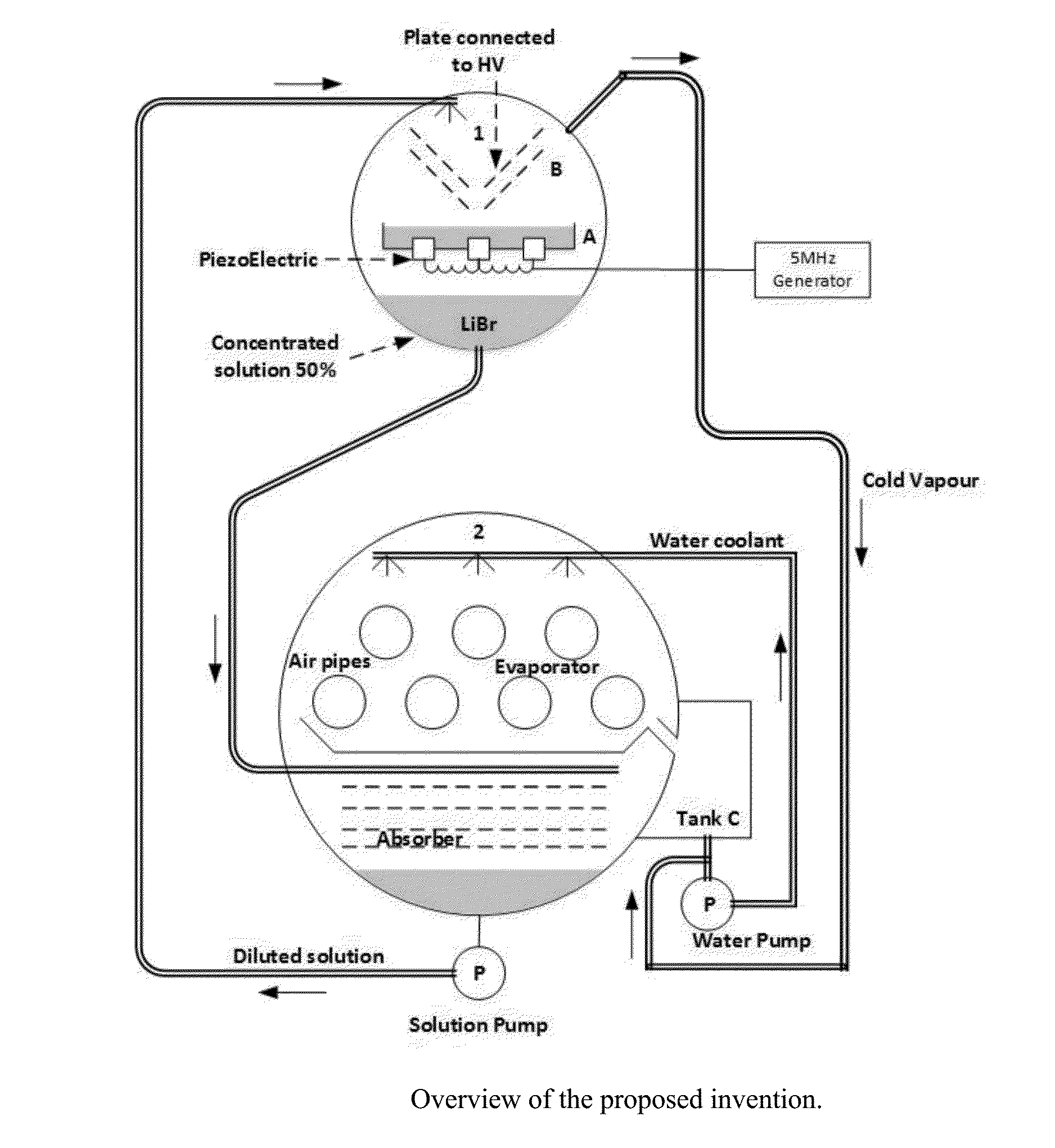

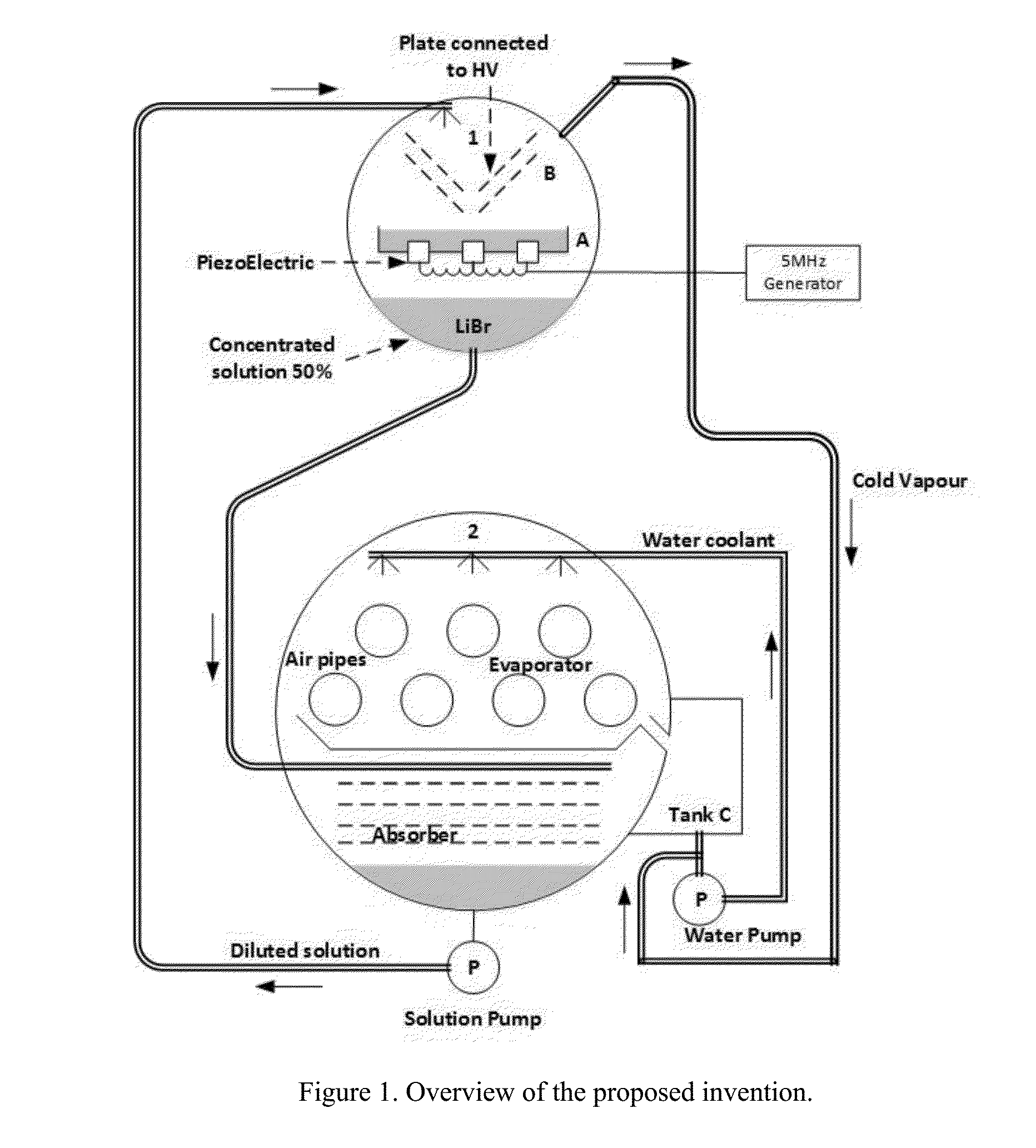

[0017]This section makes frequent references to FIG. 1.

[0018]The sections of the device, as shown in FIG. 1, include a generator (1) which is a tank that contains a concentrated solution of Lithium Bromide. Above this solution there is a container with piezo electric elements oscillating at a frequency of 5 MHz that evaporate the diluted Lithium Bromide solution. All the tanks in the device are kept at 50 mmHg vacuum. After the evaporation of the Lithium Bromide solution a high voltage of approximately 10 kV, is applied to the pallets (B). This will absorb the Lithium Bromide salt and the water vapour will exit the tank (1) from the top pipe.

[0019]In this stage the pressure of tank (1) is 400 mmHg. This pressure difference between Tank (1) and tank (2) will cause the water vapour to flow towards tank (2) and into the water pump. Here, the water vapour will mix with the existing water and will be pumped towards the evaporator. The pumped water will then be sprayed onto the evaporator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com