Chemically Decomposable Epoxide Resin System

a technology of epoxide resin and cured epoxide, which is applied in the field of chemically decomposable can solve the problems of difficult recycling of cured epoxide resin systems, economic problems, and inability to recycle by melting or dissolving analogous to thermoplastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

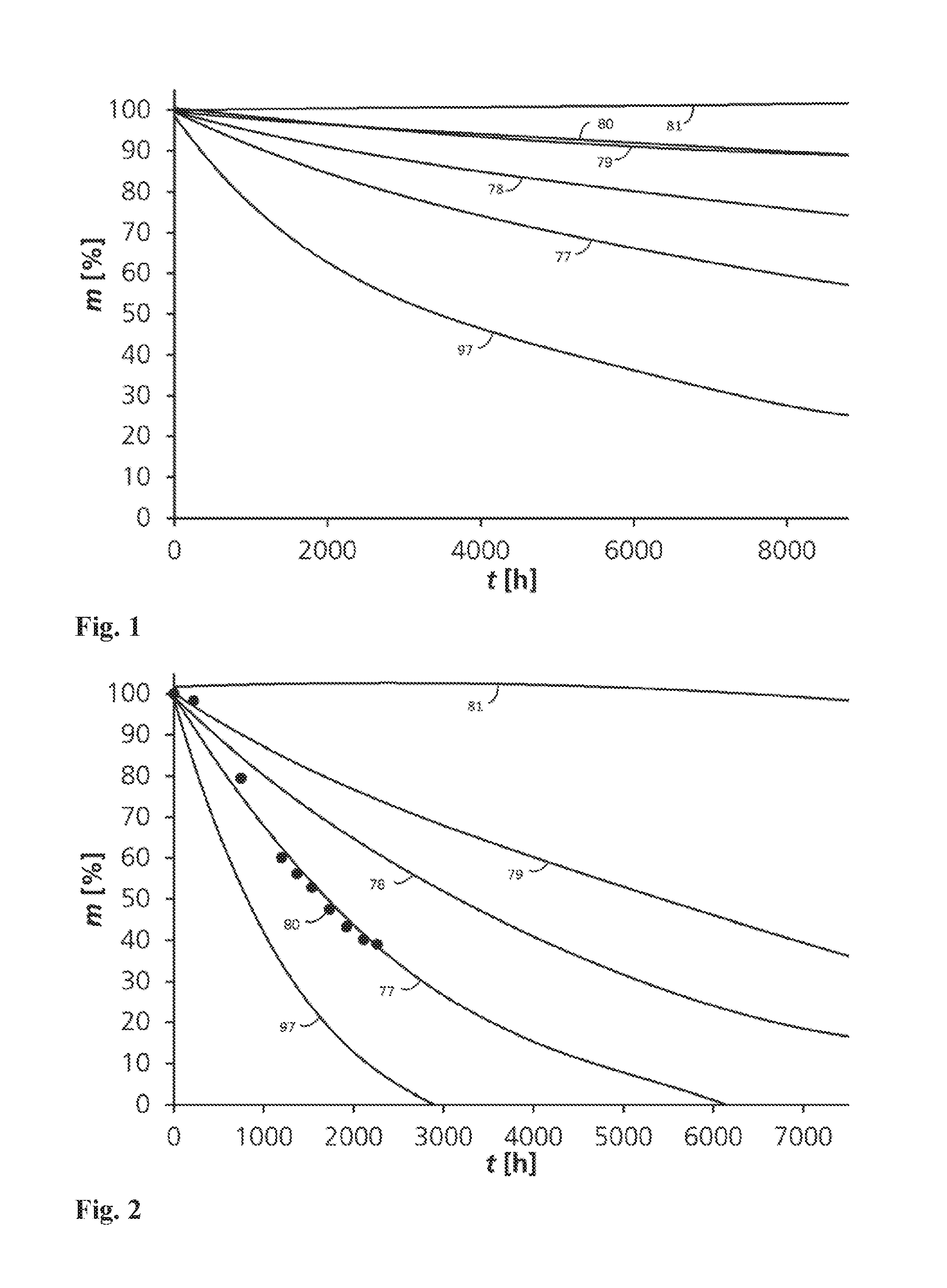

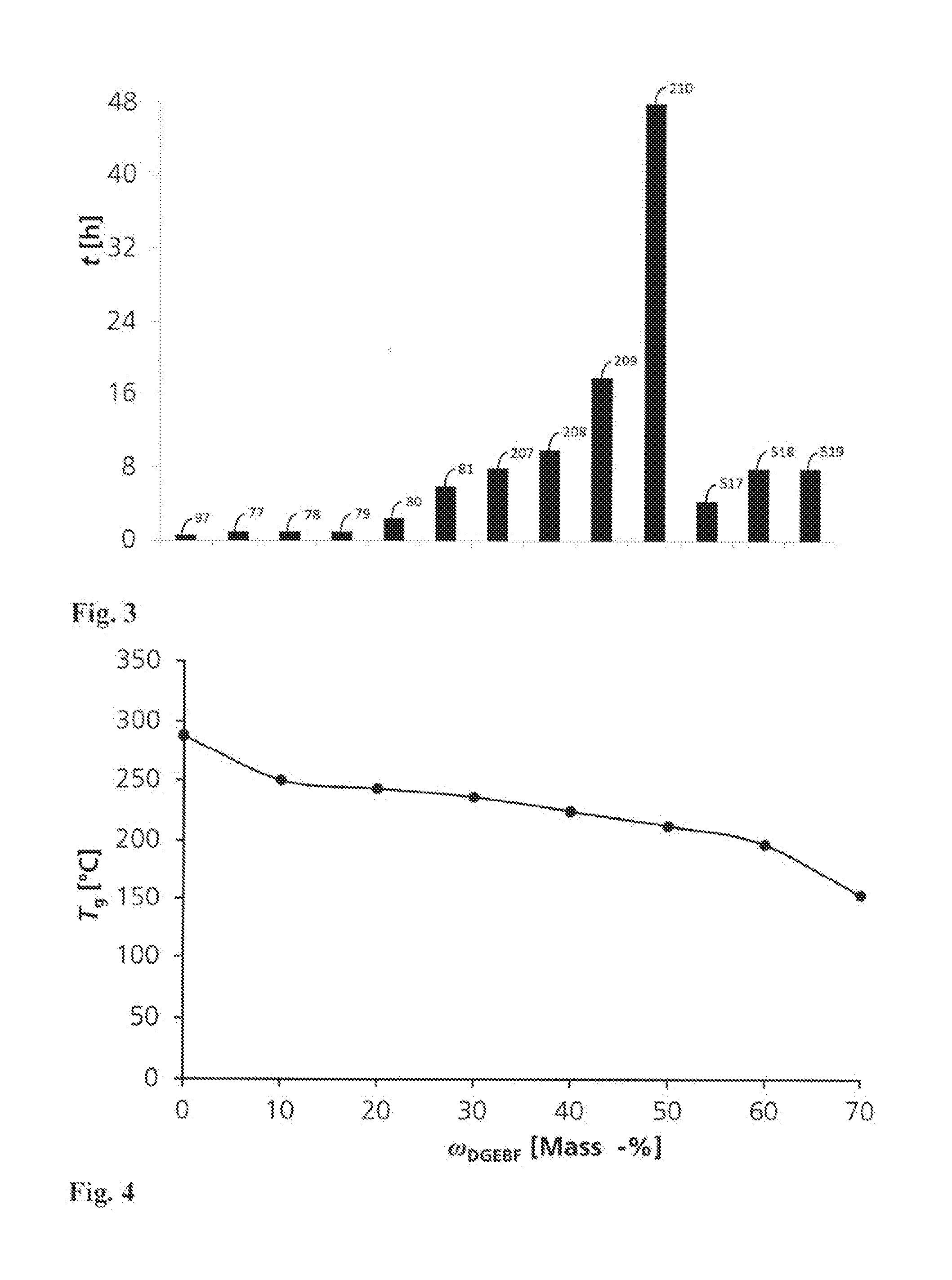

[0035]FIG. 1 shows the dependency of normed sample mass on the ordinate axis on the decomposition duration on the abscissa axis for different samples at 20° C. 2-aminoethanol was used as recycling agent. The homopolymer 1,1′-bis(4-cyanatophenyl)ethane, also called LECY, shown in formula V can be decomposed in a relatively short period of time. This is illustrated by the graph 97 in FIG. 1. The decomposition times increase with increasing DGEBF-content when LECY is used as a curing agent for the epoxide resin diglycidyl ether of Bisphenol F, also called DGEBF. The polymer 80 with 40 mass-% DGEBF shows a different decomposition behaviour than those with less or more epoxide resin: the sample body decomposed into several small pieces which prohibited an exact weighing. The polymer 77 has a DGEBF mass content of 10 mass-%, the polymer 78 a mass content of 20 mass-%, the polymer 79 a mass content of 30 mass-% and the polymer 81 a mass content of 50 mass-%. No significant decomposing coul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| cross-linking density | aaaaa | aaaaa |

| mass-% | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com