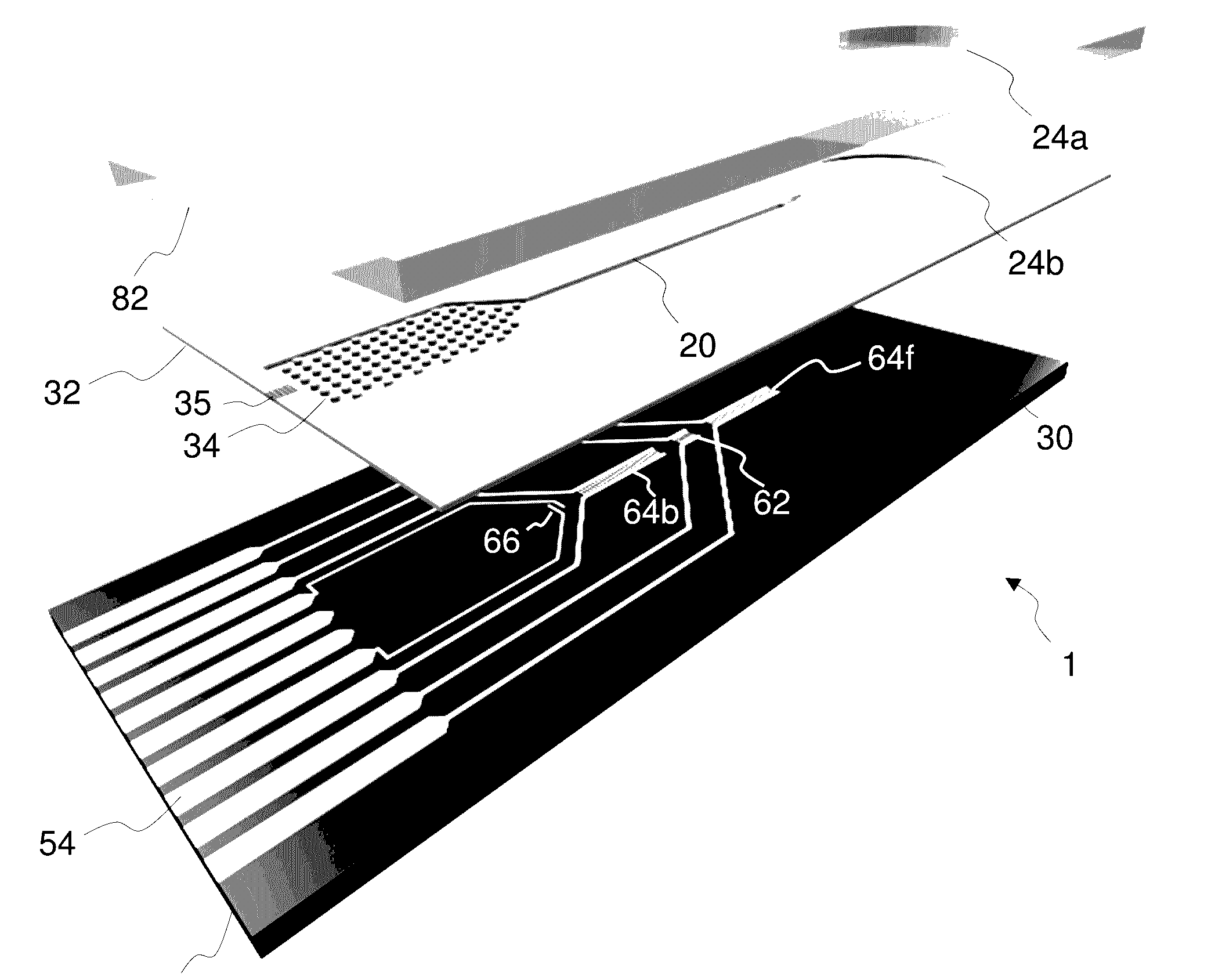

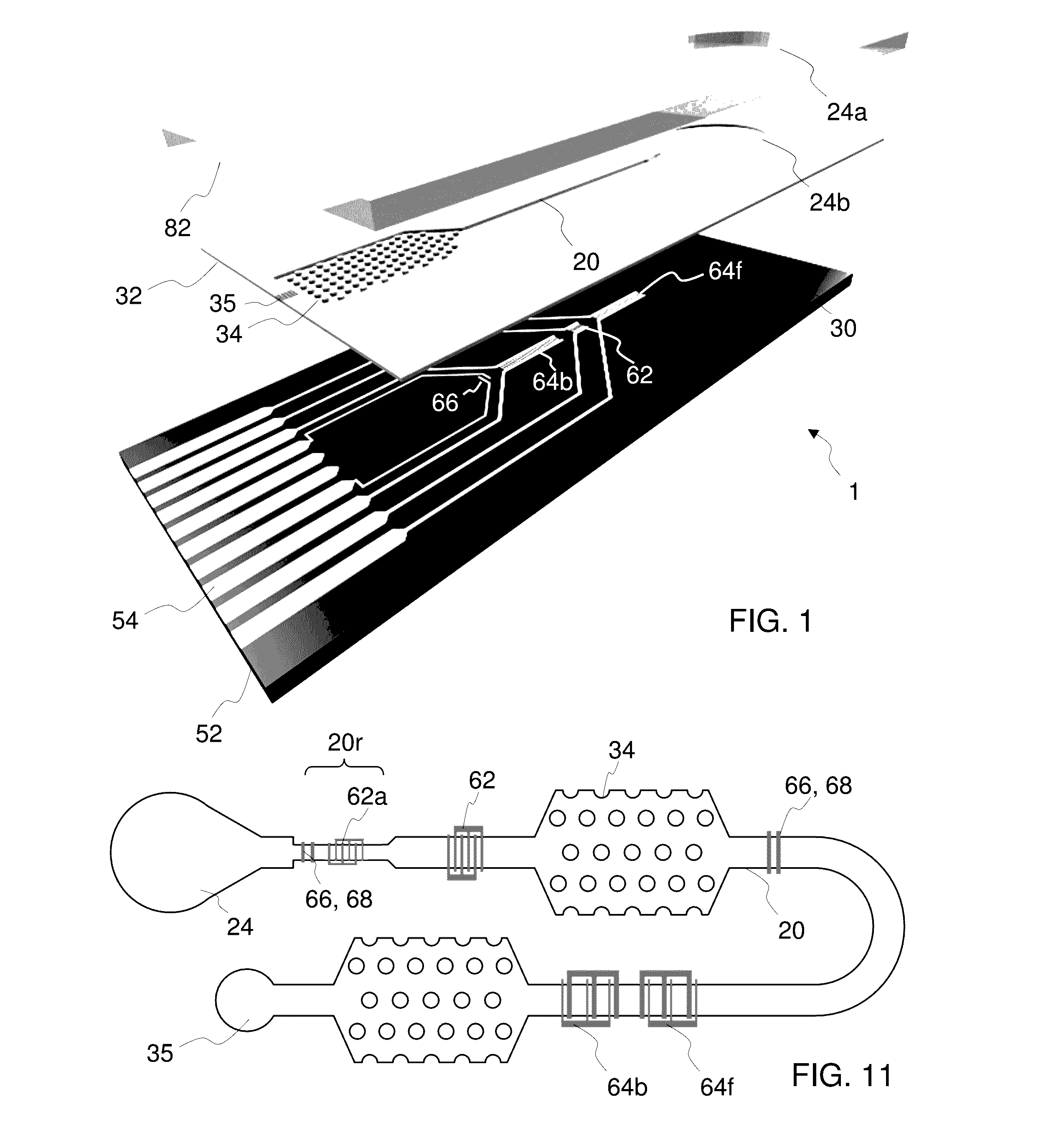

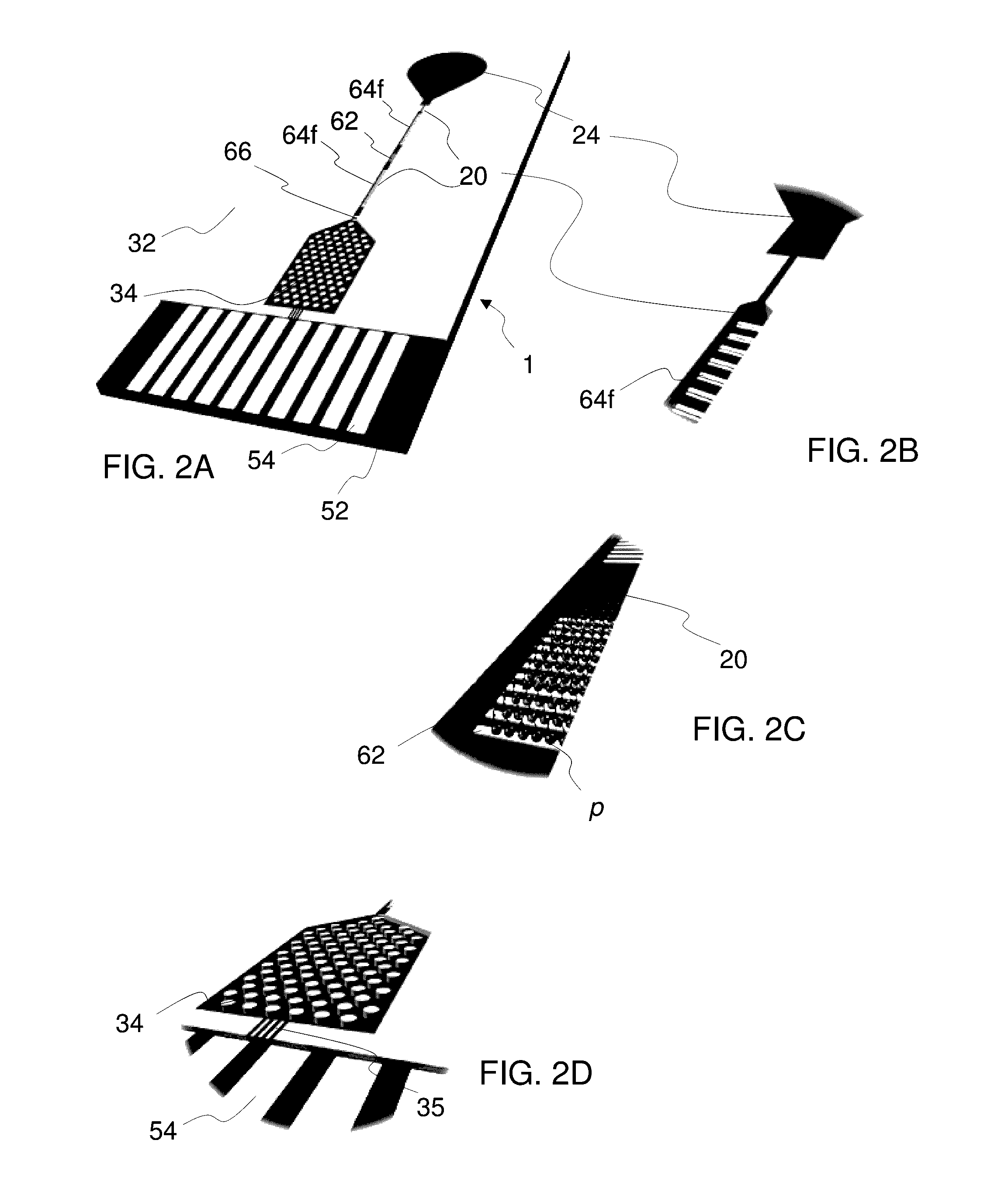

Microfluidic chip with dielectrophoretic electrodes extending in hydrophilic flow path

a technology of dielectrophoretic electrodes and microfluidic chips, applied in the field of microfluidic chips, can solve the problems of incompatibility with the requirements of microfluidic chip fabrication, manufacturing processes and cost of fabrication, and methods that lack flexibility or operate with limited sample types and flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments / technical implementation details

3. SPECIFIC EMBODIMENTS / TECHNICAL IMPLEMENTATION DETAILS

3.1 Example of Fabrication Methods

3.1.1 Using Thick Resist / Dry-Film for Microfluidic Structures

[0134]The substrate can be silicon or glass. Electrodes are patterned on the substrate, e.g., Al (50 nm). Channel patterning is carried out via exposed and developed SU-8 (or dry-film photoresist). The cover can be PDMS, laminate, plastic, etc. The SU-8 is initially hydrophobic, therefore a surface treatment is required, e.g., a 2-3 s cold plasma activation of SU-8 and Si / SiOx chip for achieving hydrophilic surfaces. Such a fabrication provides relatively low resolution and requires quite demanding photolithography steps to eliminate cracks and delamination. A dry-film resist is easier to process and can be initially hydrophilic, i.e. no need for plasma activation. A similar type of dry-film resist can be used to cover the microfluidic structures. Vias (loading pad and air vents) can be on the cover or silicon.

[0135]An example of spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequencies | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com