Water minimizing method and apparatus for use with evaporative cooling devices

a technology of evaporative cooling and water minimizing, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, heating types, etc., can solve the problems of increasing the cost of operating the system, affecting and wasting cooling water. , to achieve the effect of improving the efficiency and effectiveness of evaporative cooling systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

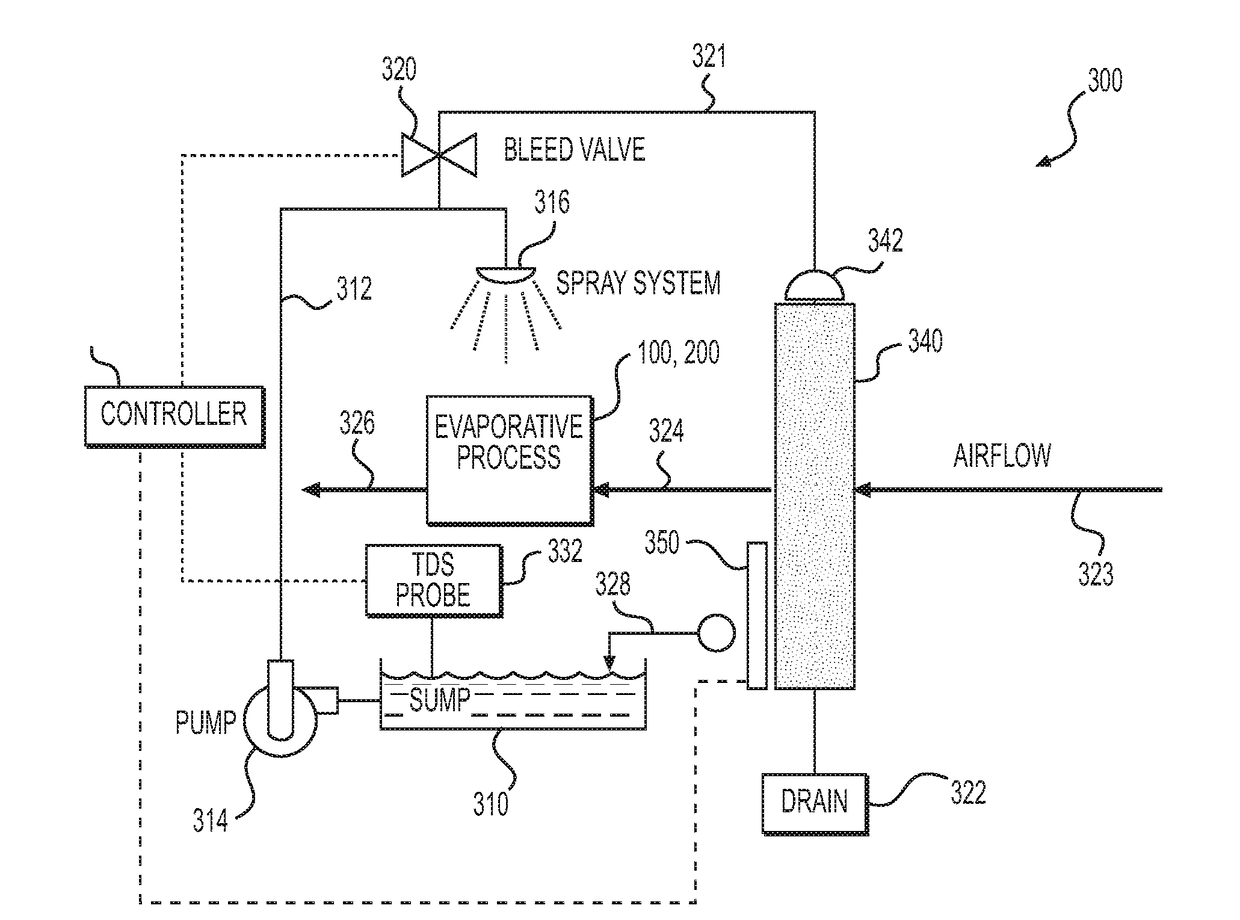

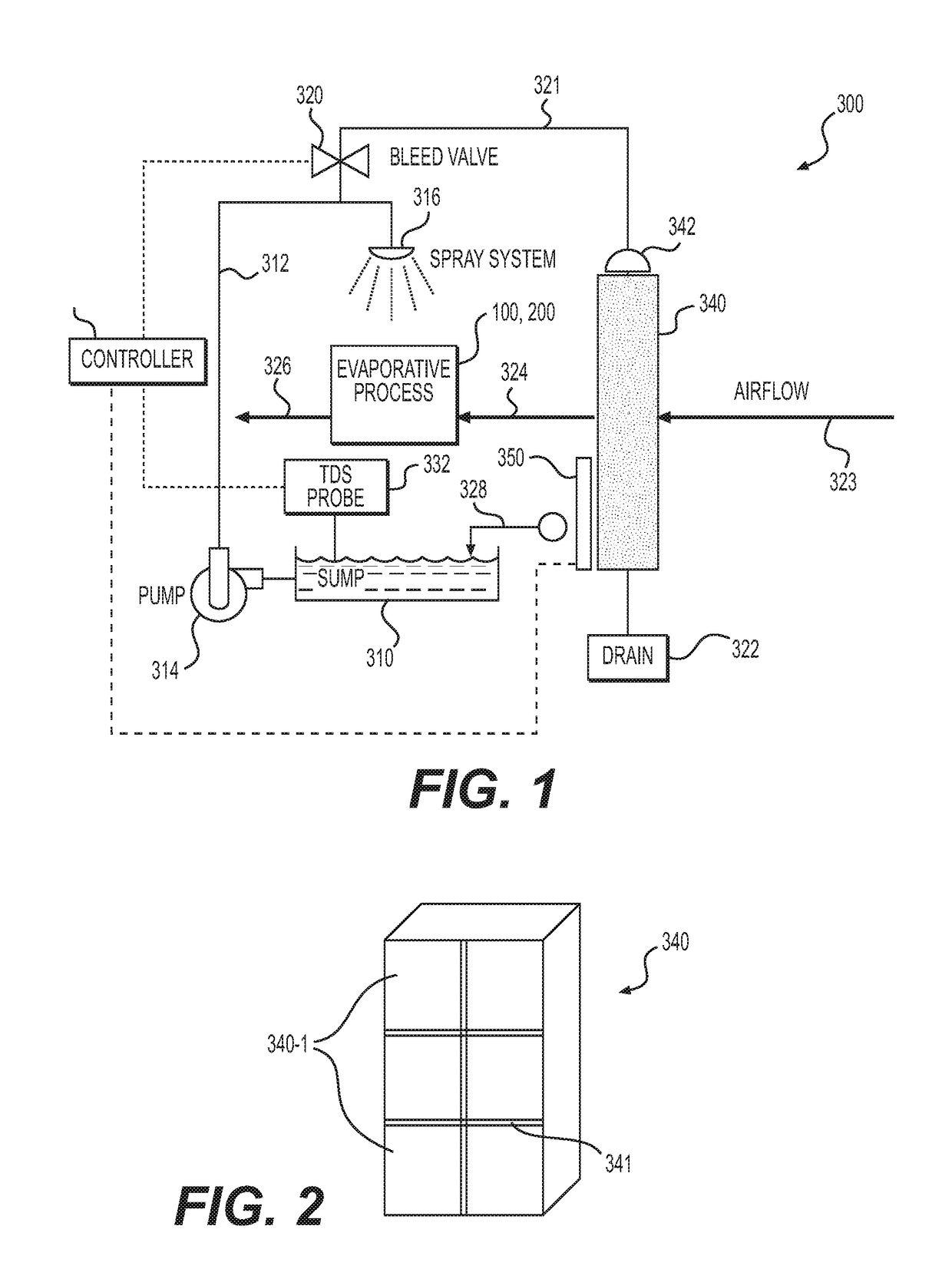

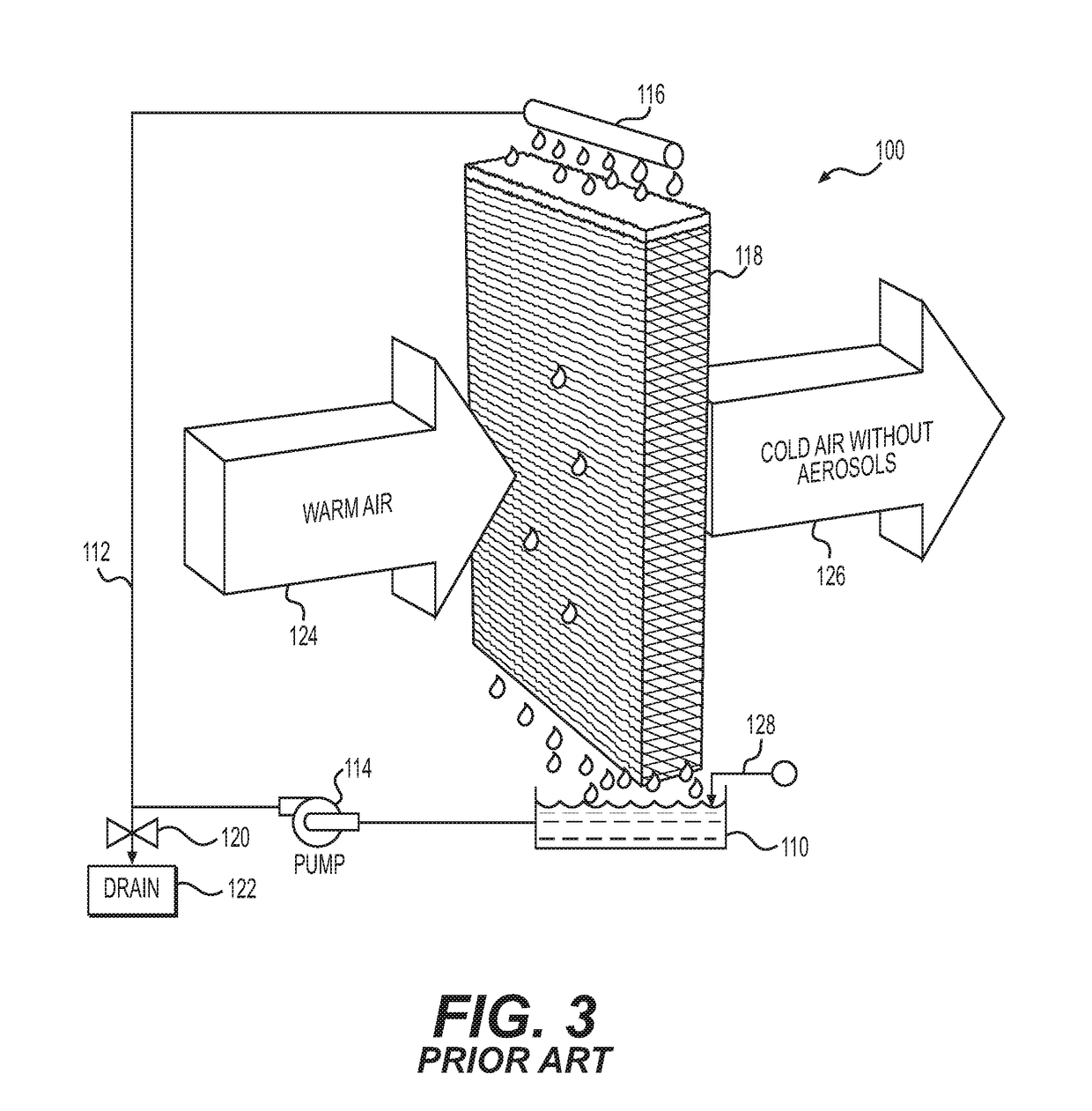

[0024]In a system of the present invention, the bleed water from an evaporative cooler is utilized to cool the air entering an evaporative section of a typical evaporative cooling system, such as a system described above with respect to FIGS. 3 and 4. This is accomplished by passing the bled water over dewatering media, or mineral removal media (MRM), which is itself a direct evaporative cooling section. The mineral removal media cools and humidifies the air before entering a principal evaporative cooling process described above.

[0025]The evaporative cooling device following the MRM media can be of any type, including, as discussed above, the direct evaporative type where water is evaporated into the air as a means to cool the air and the indirect evaporative type where water is evaporated into an air stream as a means to cool a third fluid contained in a heat exchanger that is wetted in the evaporative cooling zone, and even a cooling tower, where water is evaporated to an air stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com