Electrically and Magnetically Enhanced Ionized Physical Vapor Deposition Unbalanced Sputtering Source

a technology of ionized physical vapor and target material, which is applied in the direction of vacuum evaporation coating, semiconductor/solid-state device details, coatings, etc., can solve the problems of unbalanced magnetic field lines on the cathode target surface that form a magnetron configuration from the center, and achieve the effect of eliminating negative voltage bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

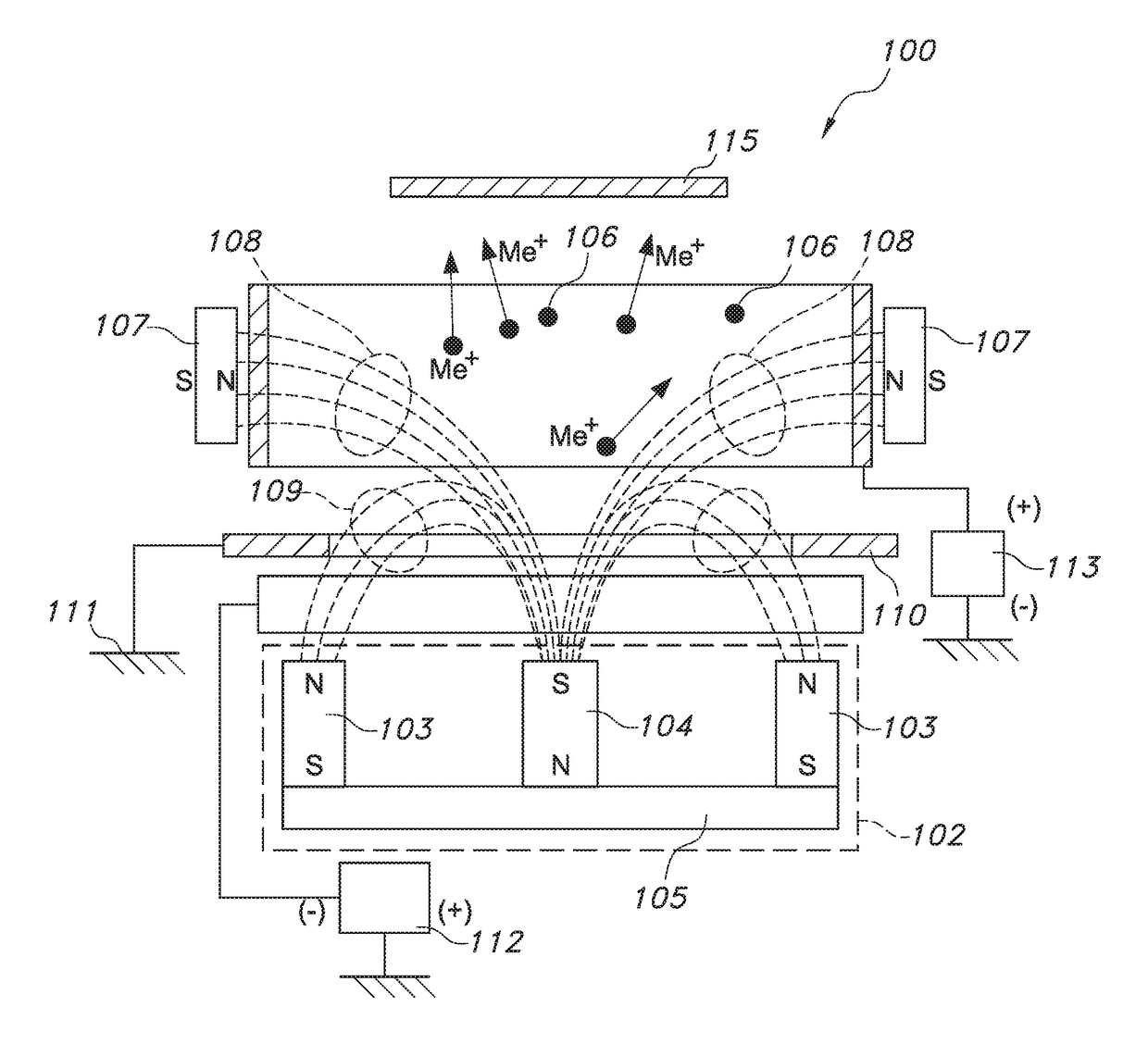

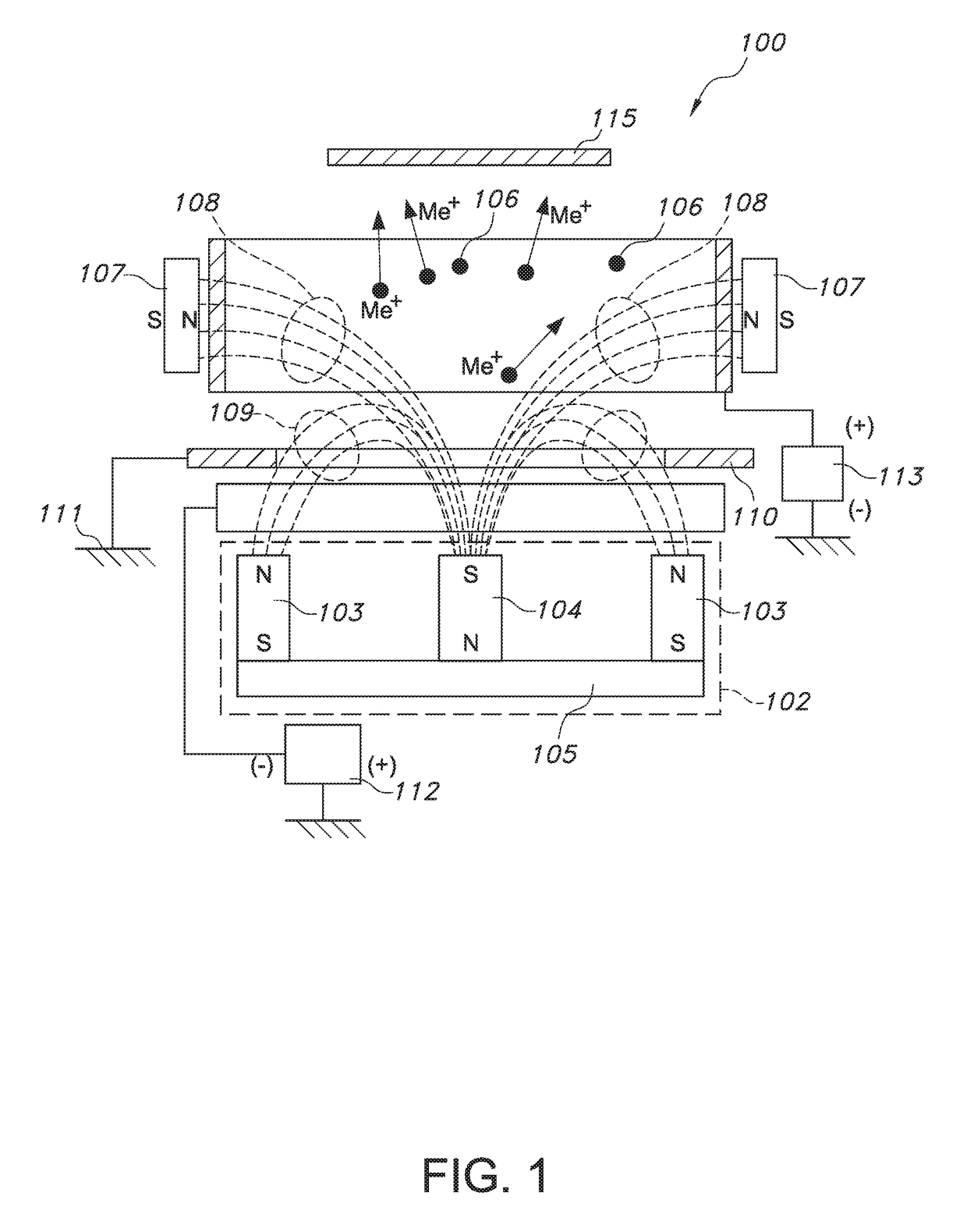

[0034]FIG. 1 shows a cross-sectional view 100 of magnetic field lines in an embodiment in which an additional electrode 106 has one magnet assembly. A cathode magnet assembly 102 includes magnets 103, 104 and magnetic pole piece 105. The cathode magnet assembly 102 forms a magnetron configuration with magnetic field lines 109 near a target surface 101. A portion of the magnetic field lines 108 cross the additional electrode 106 and terminate on the magnet 107. The additional electrode 106 is connected to a power supply 113. The power supply 113 can generate positive voltage. In an embodiment, the power supply 113 can generate high frequency bipolar asymmetrical voltages. In an embodiment, the power supply 113 can generate a radio frequency (RF) voltage with frequencies in the range of 100 KHz to 100 MHz. In an embodiment, the power supply 113 can generate a negative voltage. When the power supply 112 generates power and a magnetron discharge is formed near the cathode target 101, el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com