Etch-resistant inkjet inks for manufacturing conductive patterns

a technology of etch-resistant inkjet ink and conductive pattern, which is applied in the direction of printing, coating, inks, etc., can solve the problems of high ink viscosity, extra cost and chemical waste, and difficult reliable inkjet printing in an industrial environment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0177]This example illustrates the manufacturing of conductive patterns with UV curable inkjet inks in accordance with the invention.

Preparation of the UV Curable Inkjet Inks

[0178]The comparative UV curable inkjet ink COMP-1 to COMP-11 and the inventive UV curable ink INV-1 to INV-16 were prepared according to a composition of Type A or B in Table 9. The weight percentages (wt %) were all based on the total weight of the UV curable inkjet ink.

TABLE 9wt % in the inkjet inkComponentsType AType BDye-11.001.75Polymerizable composition according86.00 82.25 to Table 4ITX4.005.00EPD4.00—TPO4.002.00BAPO—3.00Irgacure ™ 907—5.00INHIB1.001.00

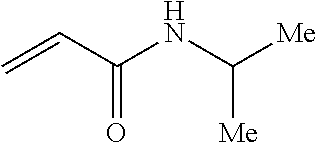

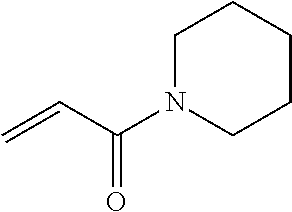

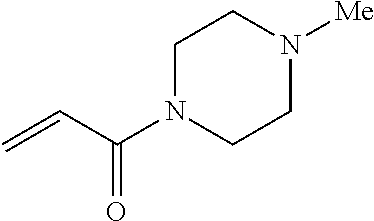

[0179]The amount and type of monomers used in the polymerizable composition of the inkjet inks are shown in Table 10. The weight percentages (wt %) in Table 4 were all based on the total weight of the polymerizable composition. The viscosity was measured and is shown in Table 11.

TABLE 10Inkjet InkPolymerizable Composition for Table 9SampleTypeAcryl Amidewt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com