Polyolefin Photovoltaic Backsheet Comprising a Stabilized Polypropylene Layer

a polypropylene and backsheet technology, applied in photovoltaic energy generation, electrical equipment, semiconductor devices, etc., can solve the problems of poor weathering of polyolefin, thioester used in the presence of hals can also decrease the effectiveness of hals, and do not teach that hals and/or antioxidants impart flame resistance, etc., to achieve good weathering and low flame spread index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific embodiments

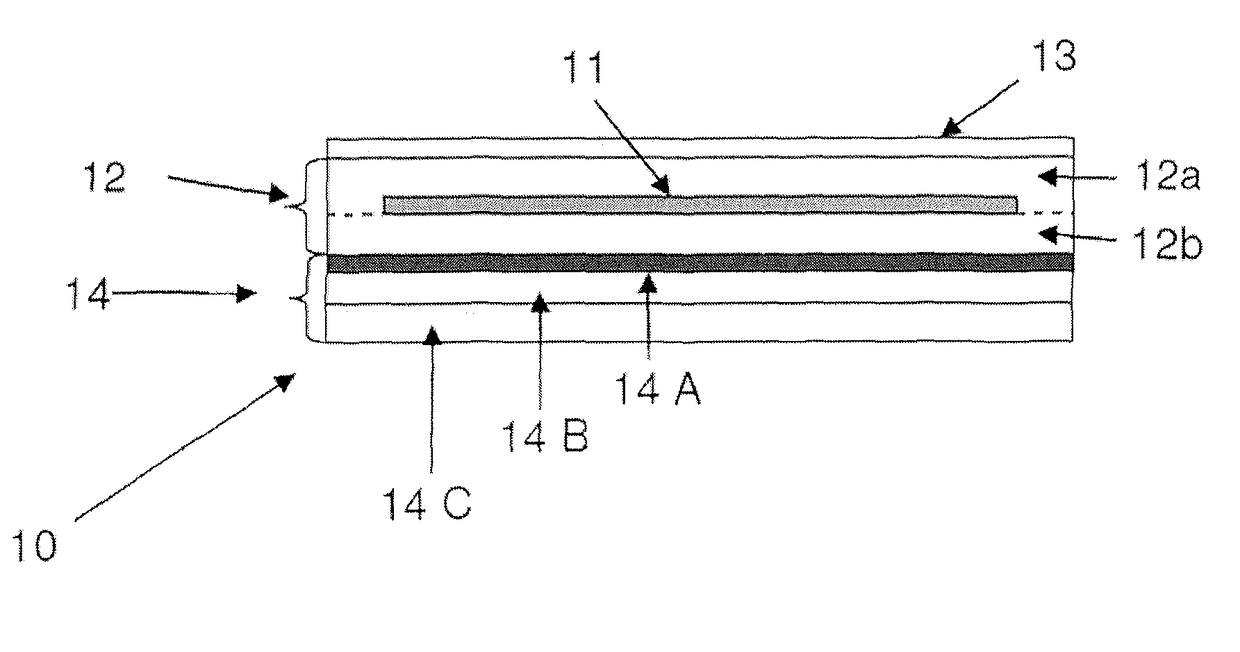

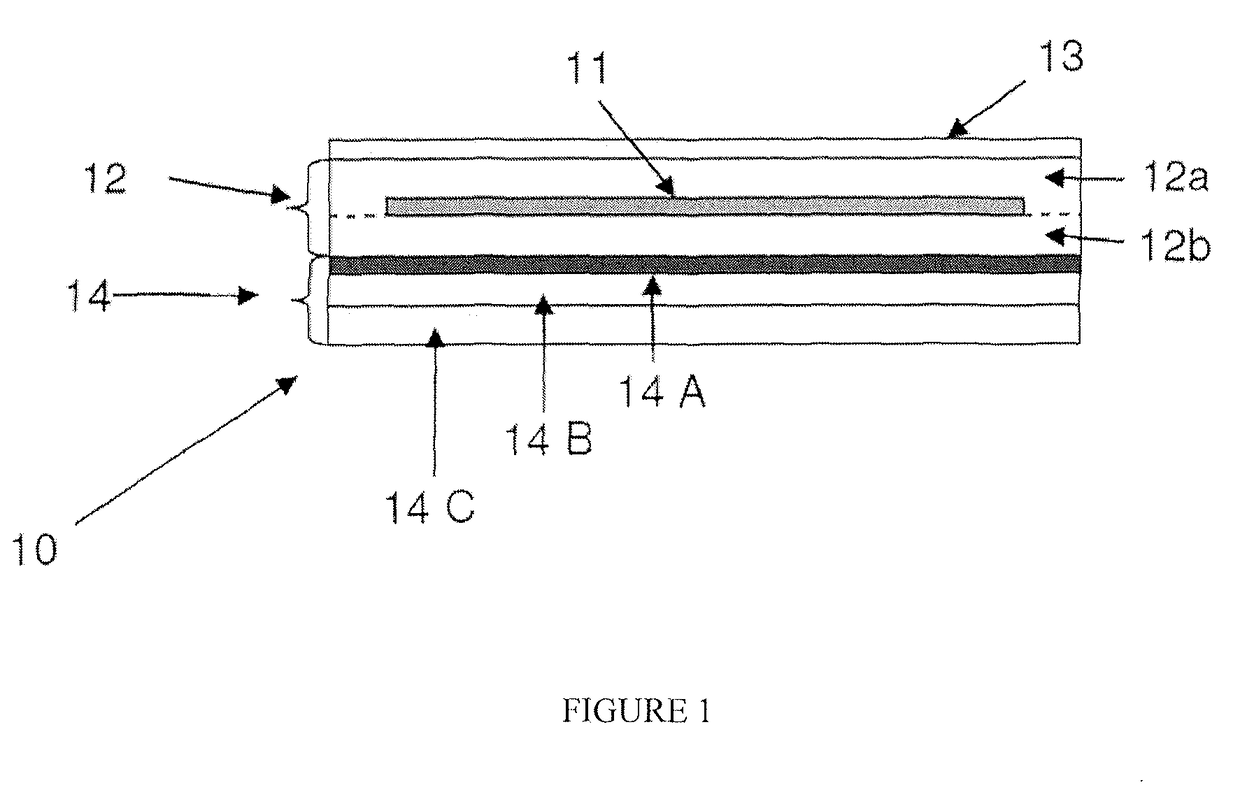

[0157]Experimental multilayer sample films (film layers indicated by letters, e.g., A, B and C) are made using the thermoplastic resin materials reported in Tables 1 and 2. Where indicated, the melt flow rates (MFR) are measured according to ASTM D1238 (230° C. / 2.16 kg) and reported in grams per 10 minutes (g / 10 min) and melt index values (MI) are measured according to ASTM D1238 (190° C. / 2.16 kg) and reported in g / 10 min. The density is measured according to ASTM D792 and given in grams per cubic centimeter (g / cc). The polypropylene polyolefins all have at least one melting peak greater than 125° C. and heat of fusion values greater than 60 J / g.

TABLE 1Resins Used in the ExamplesDensityASTMResinD792ResinProduct nameSupplierMFR / MI(g / cc)PP 1PRO-FAX ™Lyondell-12MFR0.9006301 PPBasellPP 2D118.01 PPBraskem8.0MFR0.900PP 3INSPIRE ™ 404Braskem3.0MFR0.900LLDPE 1DOWLEX ™Dow2.3MI0.9172247GLLDPE 2GRSN 9820Dow20MI0.924NAT LLDPEPlastomerAFFINITY ™Dow1.0MI0.902PL 1880GPP-gMAHOREVAC ™Arkema150MFR0.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| RTI | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com