Ether functionalized lignin for fuel production

a technology of ether and lignin, which is applied in the field of lignin composition, can solve the problems of inability to disperse lignin, biofuel industries are struggling with food vs fuel debate, efficiency and general supply of raw materials, and lack of lignin or lignin, so as to reduce the amount of substrate, inhibit disproportionation, and increase the amount of lignin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

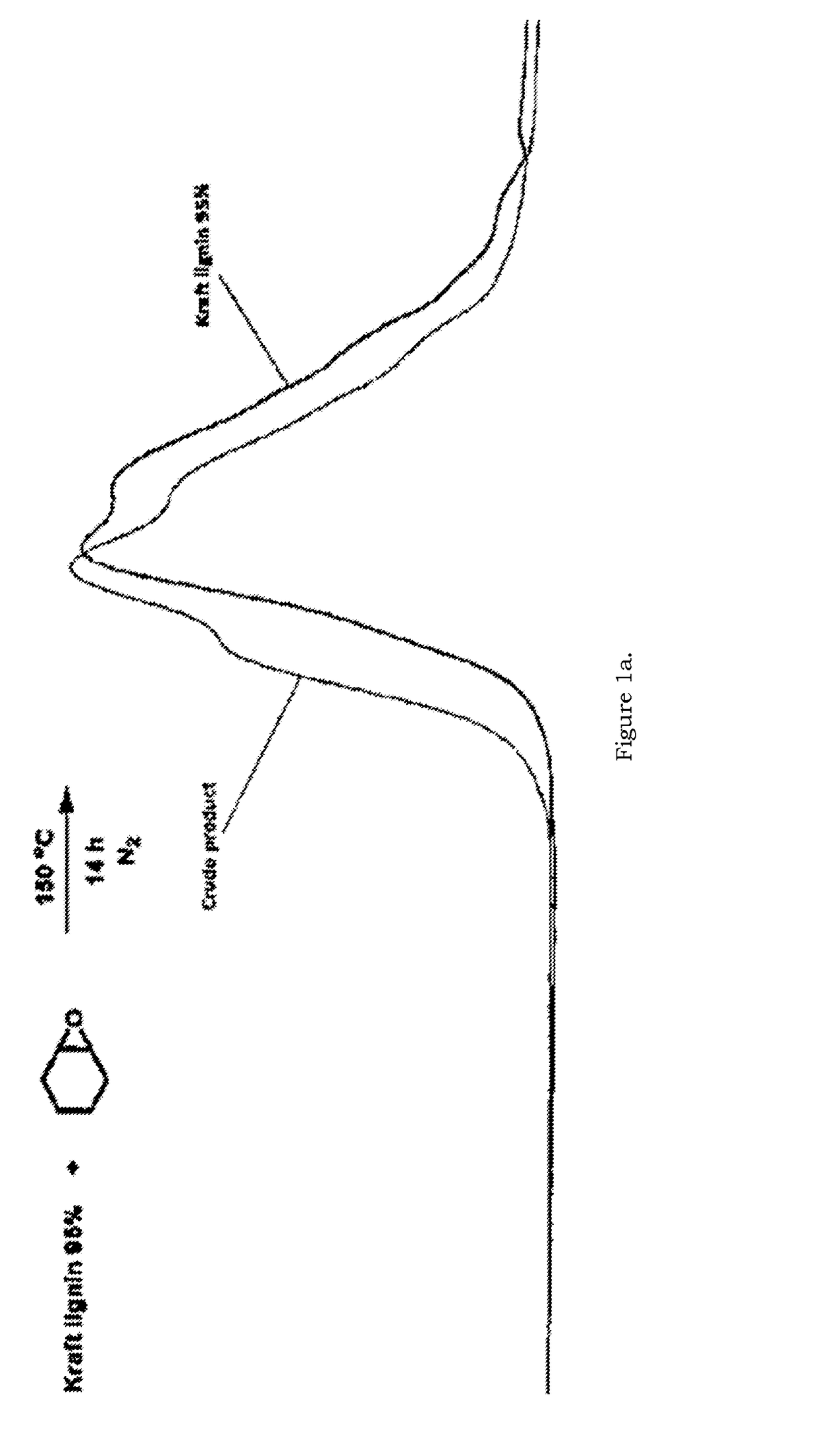

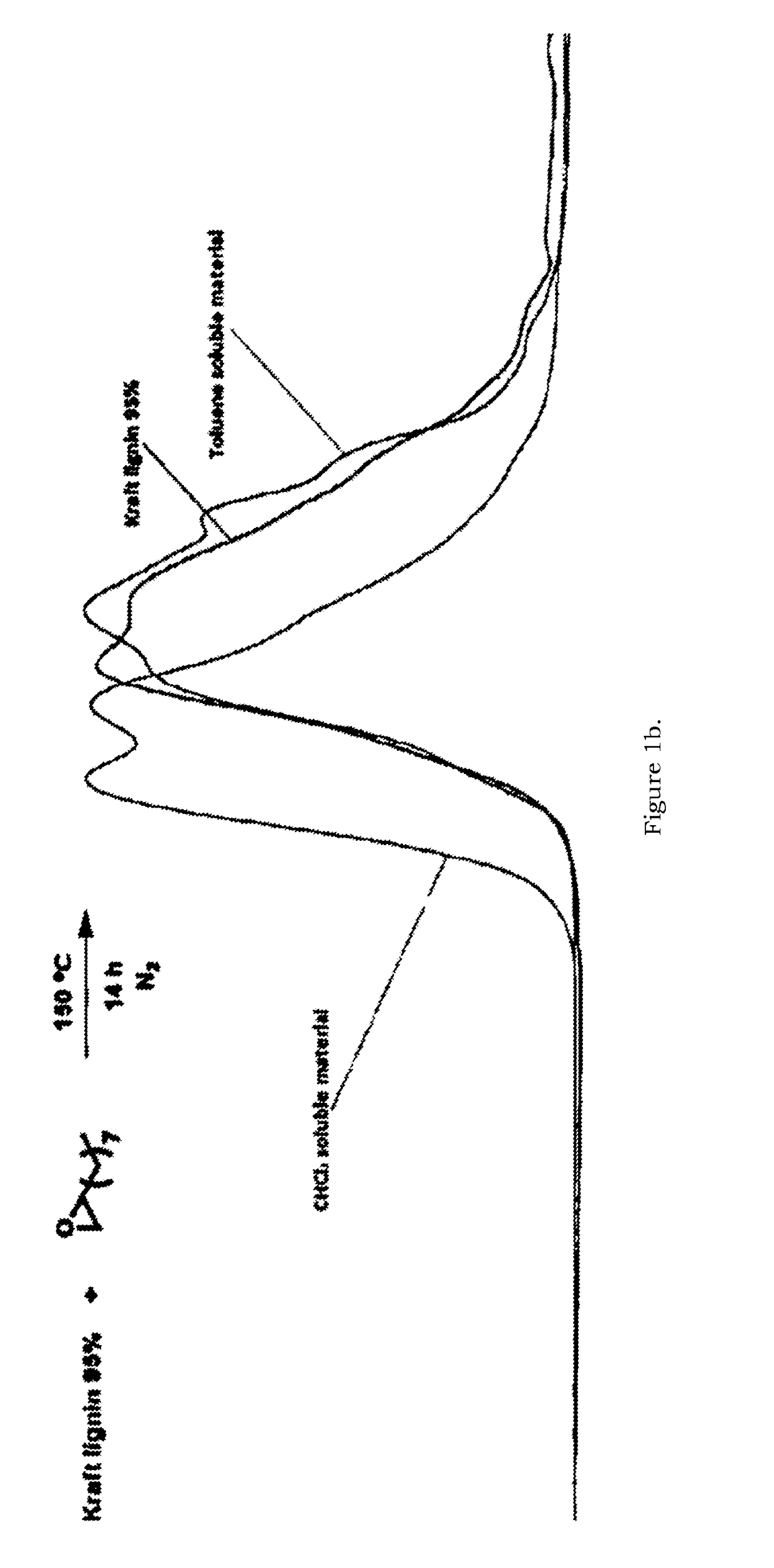

example 1

[0065]To acid precipitated lignin from black liquor was dodecylamine added in a 1:1 weight % proportion forming a mixture and heated at 150° C. over night. A fatty acid epoxide is then added in a 1:1 weight proportion to the mixture and heated again.

[0066]The etherification was determined using GPC and NMR.

example 2

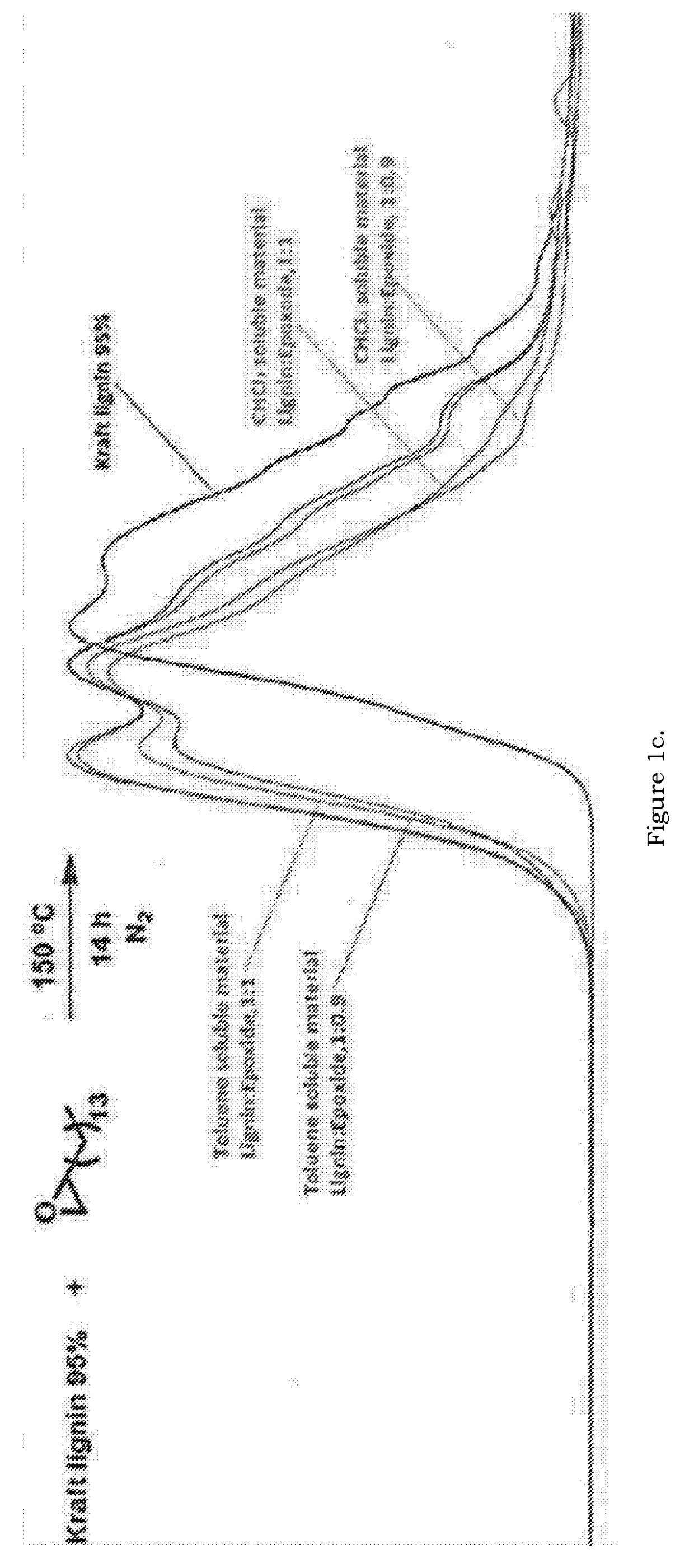

[0067]To acid precipitated lignin from black liquor was a primary epoxide (a C16 or C18) added in a 1:2.5 weight % proportion (lignin:epoxide) forming a mixture. An anhydride was then added to the mixture and left to react.

[0068]The etherification was determined using GPC and NMR.

example 3

[0069]To acid precipitated lignin from black liquor was a primary epoxide (a C16 or C18) added in a 1:2.5 weight % proportion (lignin:epoxide) forming a mixture and heated at 150 or 200° C., respectively, for 5 hours.

[0070]The etherfication was determined using GPC and NMR.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com