Method for measuring the thickness of flat workpieces

a technology for workpieces and workpieces, applied in the direction of testing/measurement of semiconductor/solid-state devices, lapping machines, instruments, etc., can solve the problems of high demands on the flatness of workpieces, inability to meet the accuracy requirements explained above, and insufficient edge geometry for the requirements of wafer consumers, etc., to achieve reliable and precise in-situ determination of workpieces, reduce scrap volume, and simplify production logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

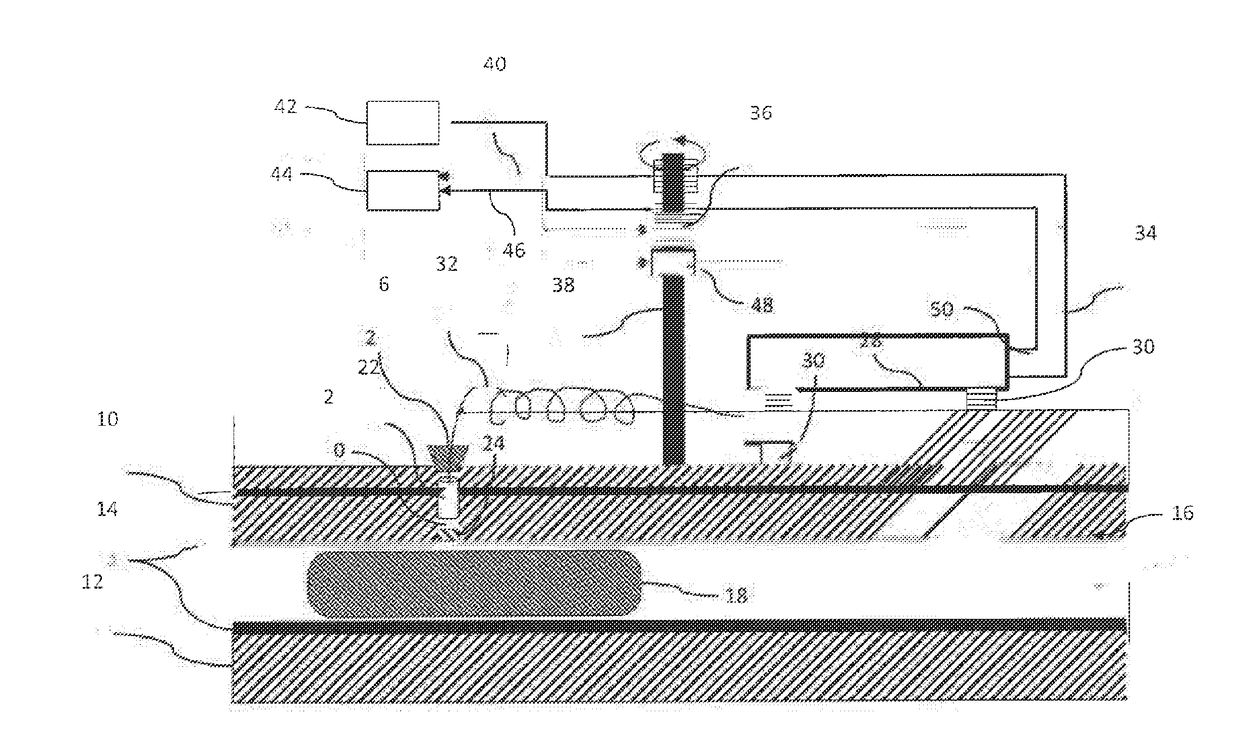

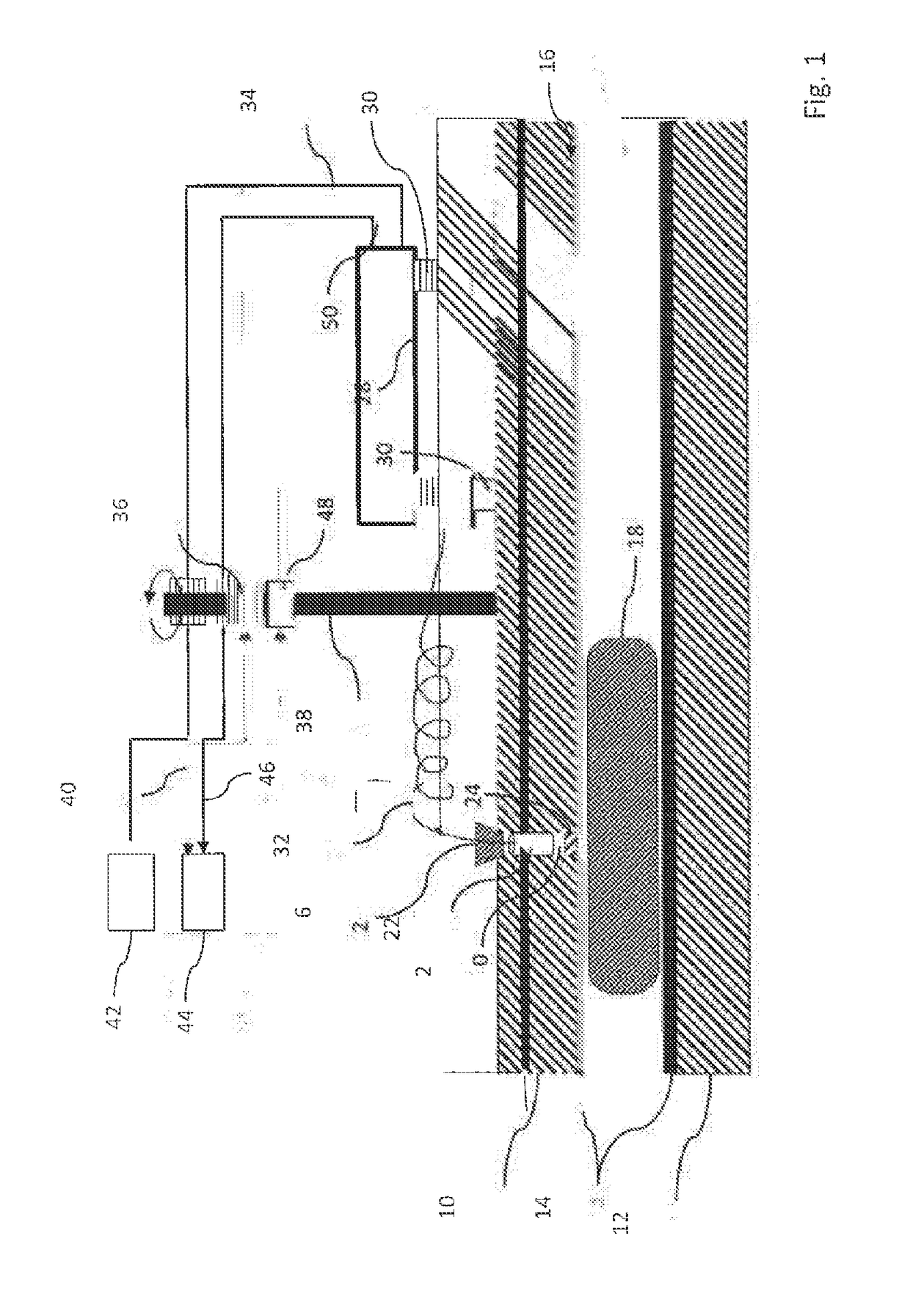

[0037]The double-side processing machine shown in FIG. 1 can, for example, be a double-side polishing machine. The double-side processing machine has an upper working disk 10 and a lower working disk 12 opposite the upper working disk 10. Part of the upper working disk 10 and the lower working disk 12 can, in each case, be a working coating 14, for example a polishing cloth. With this working coating 14, the upper and lower working disks 10, 12 delimit between them a working gap 16 for material-removing processing of workpieces. The reference numeral 18 shows, by way of example for illustrative purposes, a workpiece, for example a wafer. It is understood that, for example, rotatably arranged rotor disks can in practice be provided in the working gap 16, which rotor disks each receive multiple workpieces for simultaneous processing in the working gap 16.

[0038]In the example shown a through-hole 20, in particular a through-bore, is configured in the upper working disk 10. A focusing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com