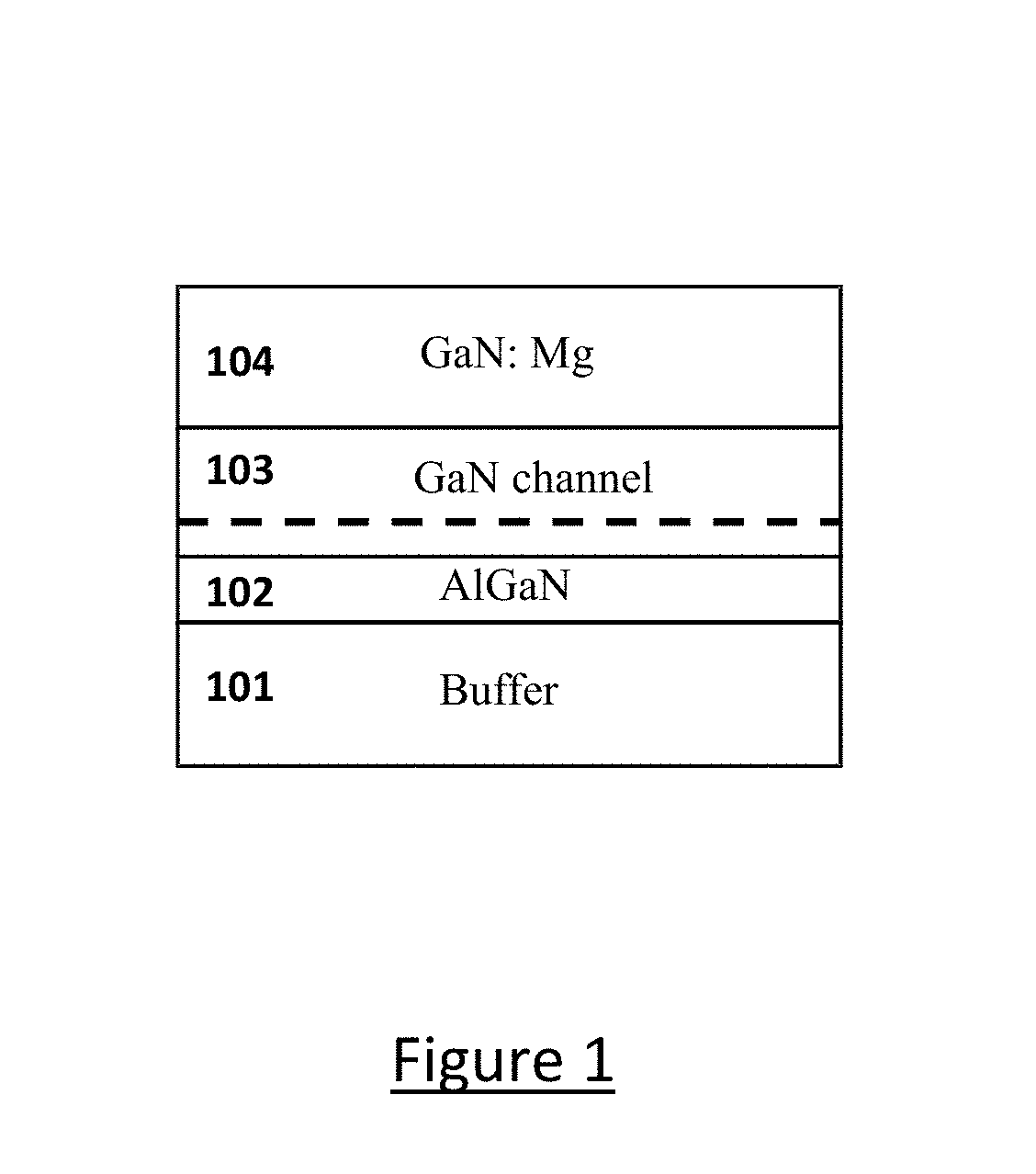

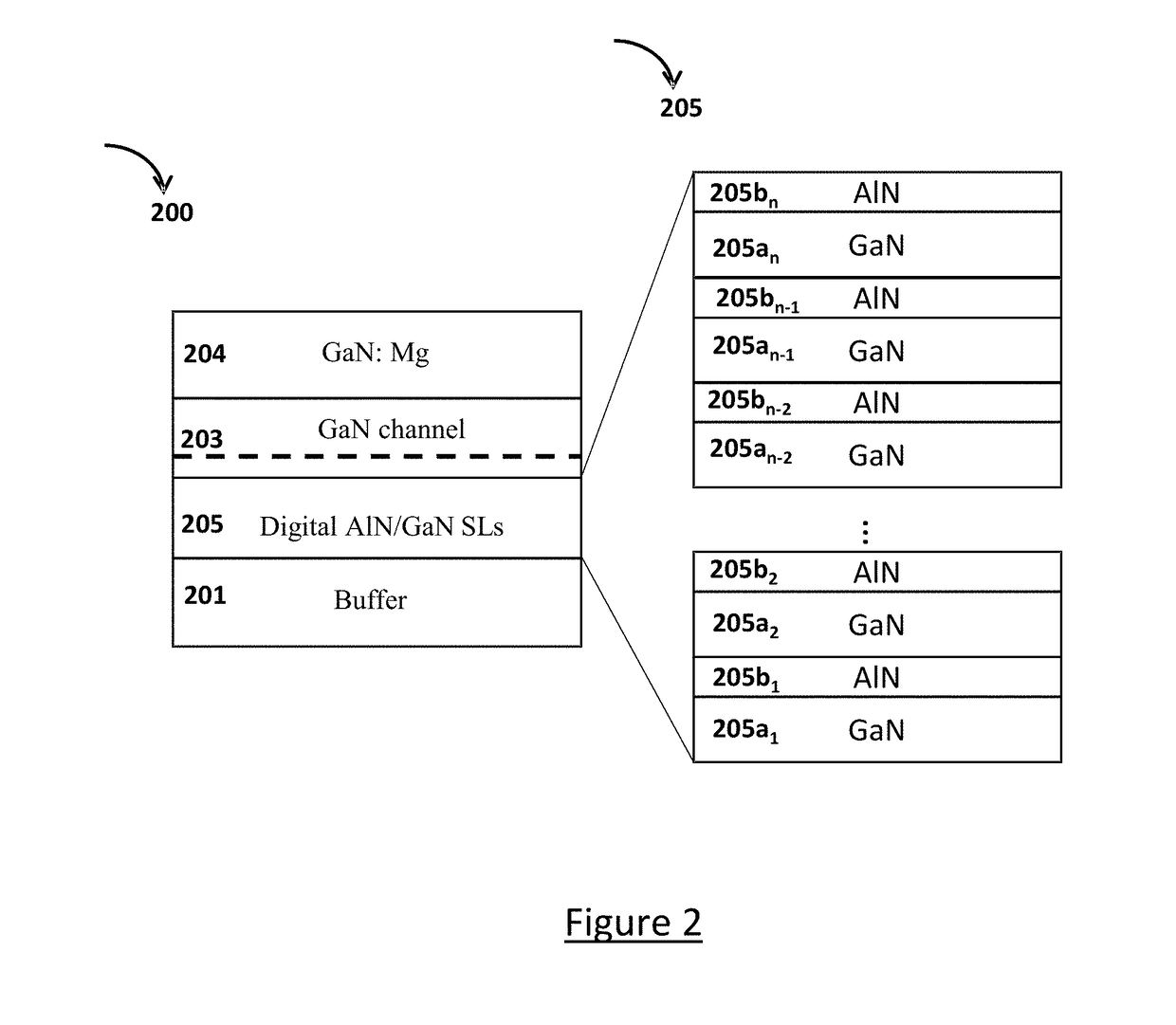

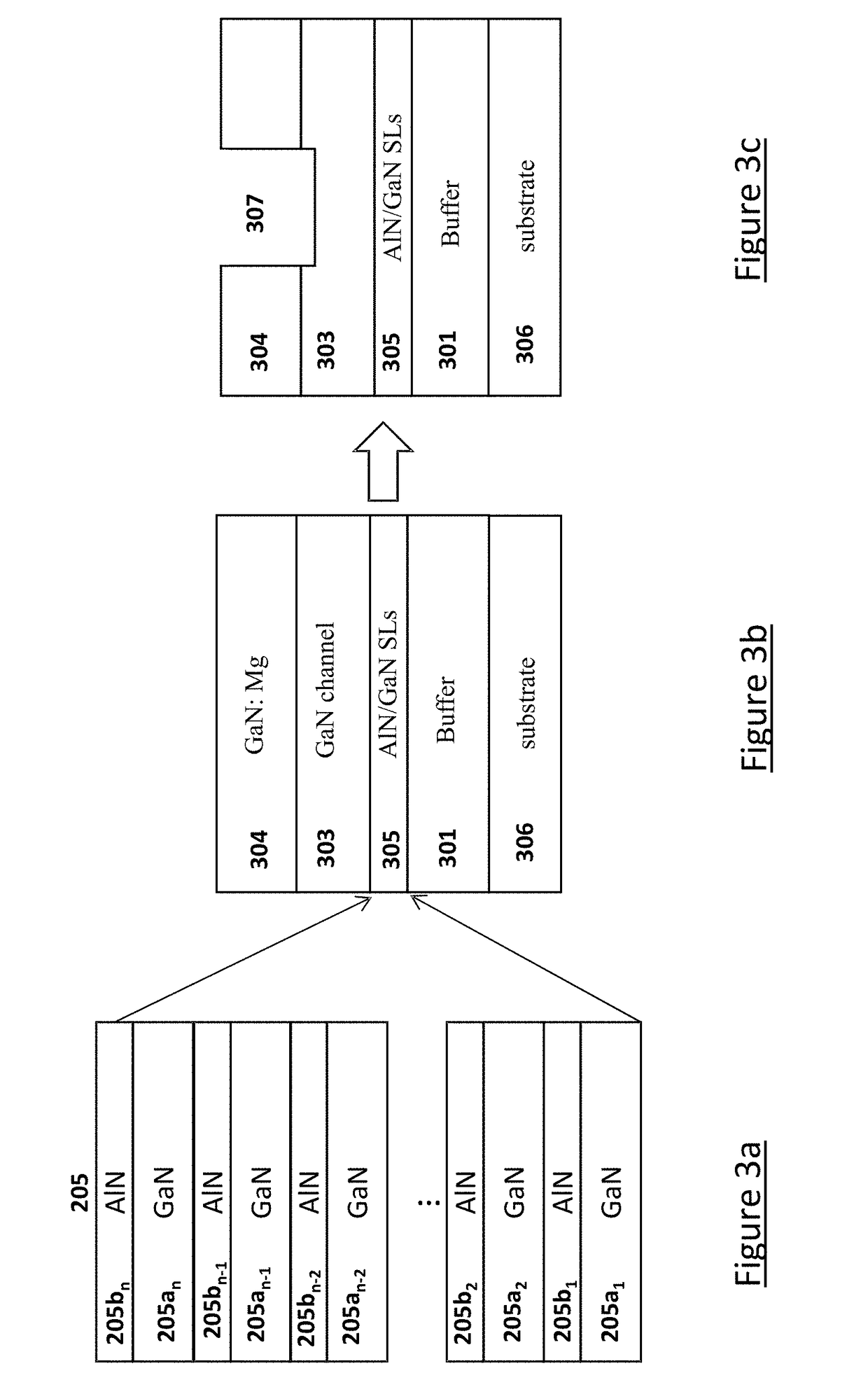

Digital alloy based back barrier for p-channel nitride transistors

a digital alloy and back barrier technology, applied in the field of iiinitride transistors, can solve the problems that thick analog algan with high al content cannot be grown on gan buffers, and the fundamental limit of using analog algan alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]It should be understood at the outset that, although example embodiments are illustrated below, the present technology may be implemented using any number of techniques, whether currently known or not. The present technology should in no way be limited to the example implementations, drawings, and techniques illustrated below. Additionally, the drawings are not necessarily drawn to scale.

[0044]Recently, GaN transistors have revolutionized high power and high speed switching electronics and there is a constant push, driven by the application demands, for higher and higher power handling capacities. GaN transistor's power handling capacity depends directly on the channel conductivity.

[0045]III-Nitride semiconductor materials (Aluminum, Indium, Gallium)Nitride are excellent wide band gap semiconductors very suitable for modern electronic and optoelectronic applications. Though this disclosure describes the technology using GaN, the proposed technology applies to any of the III-Ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com