Fluidized bed coking with fuel gas production

a coking process and fuel technology, applied in coke ovens, combustible gas production, thermal non-catalytic cracking, etc., can solve the problems of low liquid yield of transportation fuels, degrade the quantity of more valuable liquid products, and generally poor quality of liquids, so as to reduce capital costs and improve the effect of return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]In this description, the term “Flexicoking” (trademark of ExxonMobil Research and Engineering Company) is used to designate the fluid coking process in which heavy petroleum feeds are subjected to thermal cracking in a fluidized bed of heated solid particles to produce hydrocarbons of lower molecular weight and boiling point along with coke as a by-product which is deposited on the solid particles in the fluidized bed, the coke is then converted to a fuel gas by contact at elevated temperature with steam and an oxygen-containing gas in a gasification reactor (gasifier).

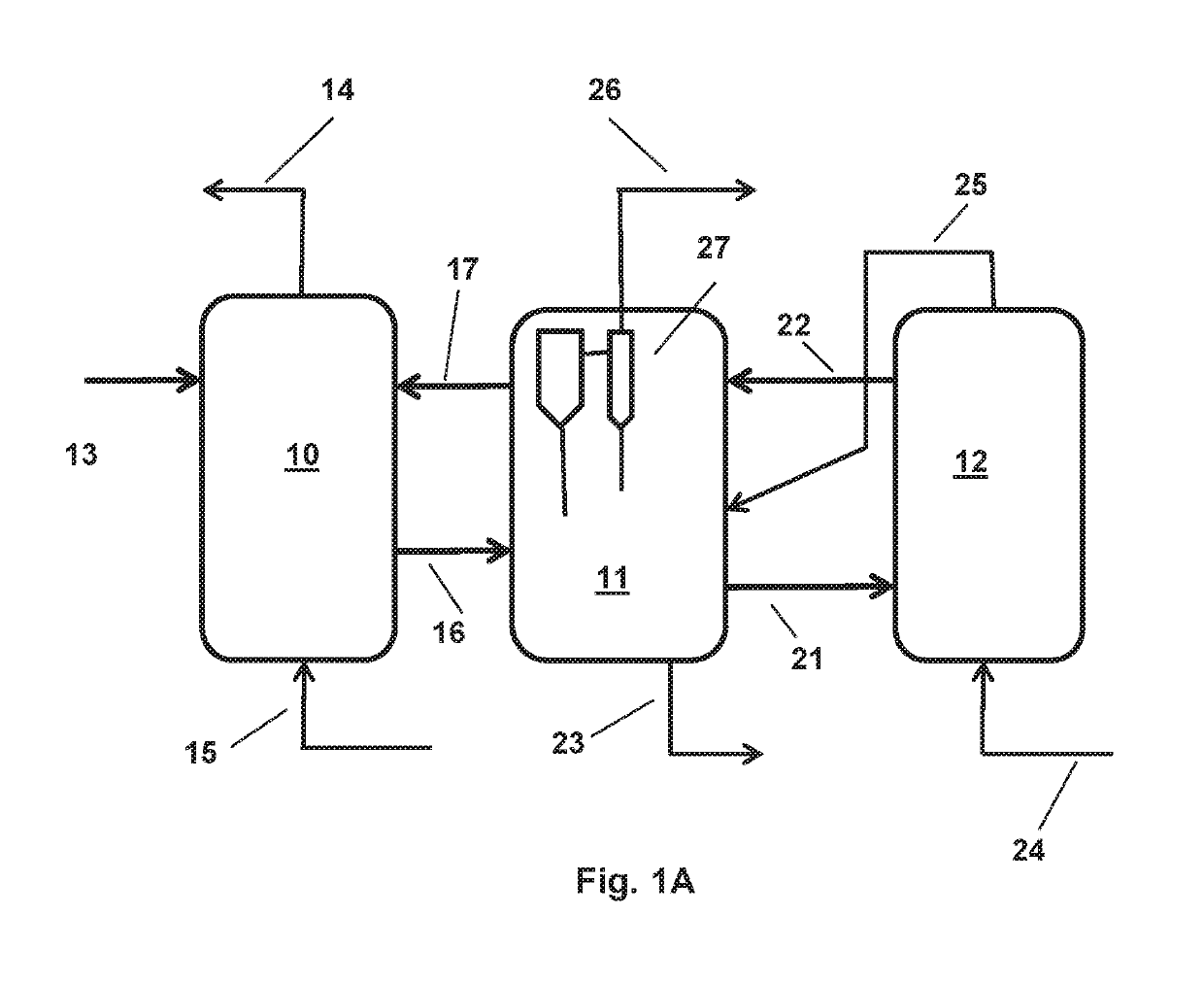

[0024]FIG. 1A shows a Flexicoker unit with its characteristic three reaction vessels—reactor, heater and gasifier—in side-by-side arrangement; although the footprint of the side-by-side arrangement is larger than that of the stacked units shown in U.S. Pat. Nos. 3,661,543 and 3,816,084, it is less subject to upsets and potential equipment failures as noted in U.S. Pat. No. 3,759,676 and has now become convention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com