Second Generation Superconducting Filaments and Cable

a superconducting and copper oxide technology, applied in the direction of superconductors/hyperconductors, superconductor devices, electrical devices, etc., can solve the problems of delamination of the superconducting layer, the architecture of the 2g tape does not allow for a simple splicing of multi-strand cables, and the loss of magnetization (ac) of the cable, so as to reduce the electrical loss of the cable and reduce the loss of the cabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

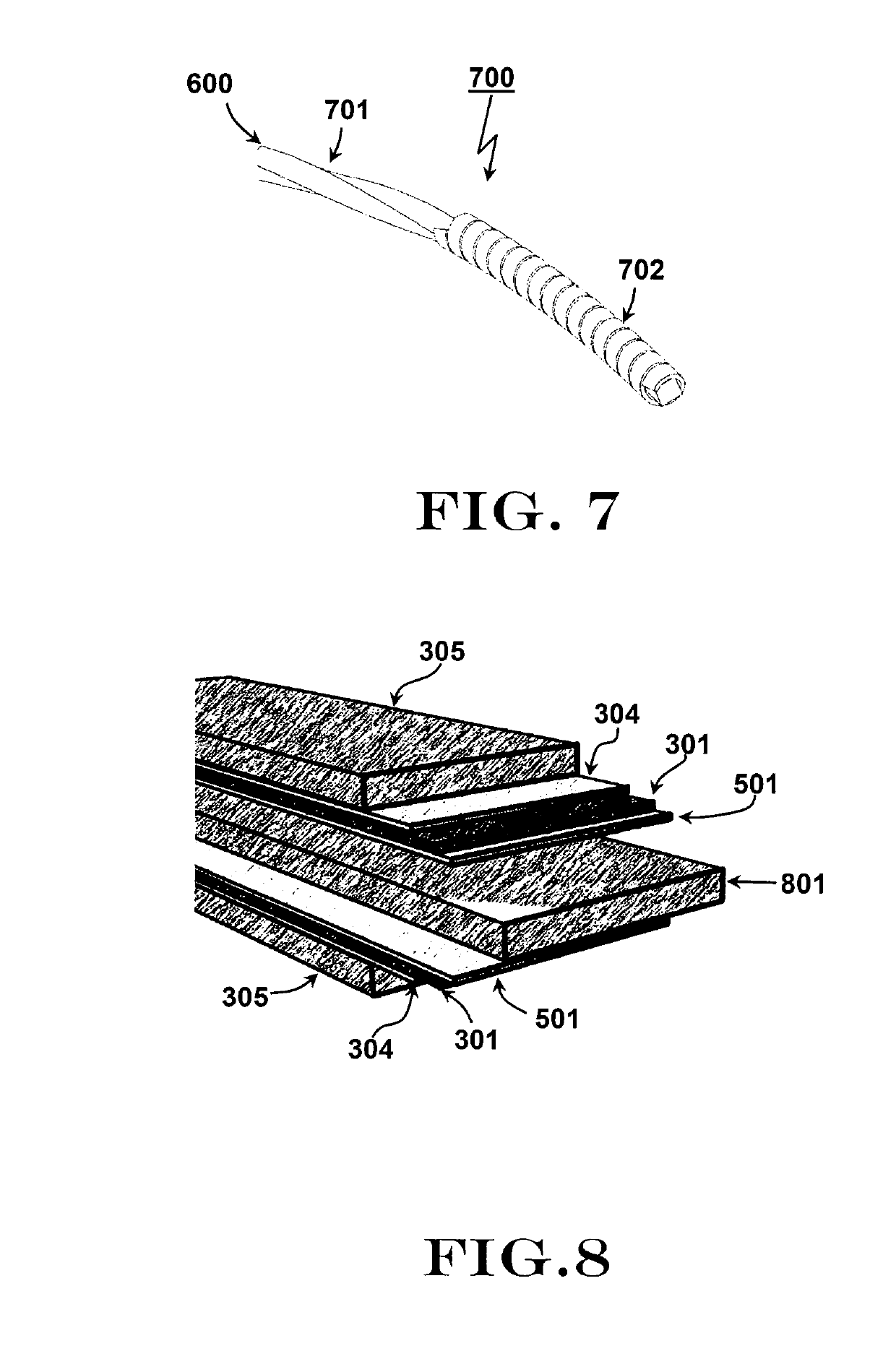

[0046]A standard wire (8602-FCL) offered by the AMSC Corp was used for the exfoliation experiments. The wire was a 10 mm wide YBCO-RABiTS tape soldered between two 12 mm wide layers of 75 μm thick 316L stainless steel foil. The YBCO layer was exfoliated after mechanically trimming the side fillets of the tape. In order to facilitate the YBCO layer delamination, the tape was rapidly heated by an inductive coil coupled to the tape. The inductive coil included 8 turns of gauge 14 litz wire wound to conform to a 16 cm long and 1 cm wide race-track shape. The coil was placed directly under the tape, which ensured good coupling of the tape to the AC field created by the coil. The coil was energized for 1-2 seconds by applying approximately 200 W of AC power, 50 KHz. The YBCO layer was immediately exfoliated from the substrate. Lengths of tape approximately 10 cm long were exfoliated in a typical run. These lengths of tape were then sliced into 1 mm-4 mm coupons by a CO2 laser. The laser w...

example 2

[0047]The transport critical current of wire coupons prepared in accordance with Example 1 was measured at 77K as a function of the width of the strip. For the measurements, the strips were soldered to 10 mm wide, 50 micron thick copper current leads using a low-temperature indium-based solder. The voltage leads were 25 micron thick copper wires attached to the strips by the low-temperature solder. The wire coupons were mounted on a test fixture and the fixture was immersed in a liquid nitrogen bath. DC current was gradually increased and the voltage was recorded as a function of the current (I-V curve). FIG. 9A shows the critical currents for a 1.5 mm wide one-ply wire coupon (single filament) and for a 1.5 mm wide two-ply wire coSupon (two filaments) at 77 K. The test data demonstrates that the current capacity of a two-ply wire coupon (two filaments is approximately double the current capacity of a one-ply wire coupon (single filament). FIG. 9B shows the I-V curves of 1 mm wide a...

example 3

[0048]The specific resistivity, defined as the resistance times the joint area, is an important parameter of a conductor. It is well known that the best results are achieved with two-component alloys, e.g., SnAg, InSn, SnPb, with RE123 pre-tinned or with an aluminum heater block to press the joint surfaces during the soldering process. In general, measured specific resistivity at 77 K ranges from >30 nΩ / cm2 to 2. In order to determine the surface resistance of the exfoliated YBCO surface, a splice of 3 mm wide filaments was prepared by soldering the filaments face to face using Indium. The I-V curves of the filament and the splice were recorded at 77 K. FIG. 10 compares the I-V curves of a 3 mm wide filament and a 3 mm wide filament containing a single splice. The 3 mm wide filament was tested and the resultant data recorded in FIG. 10. The same 3 mm wide filament was then cut, spliced back together, and tested. The resistive part of the splice I-V curve was approximated with a line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com