Heliostat Correction System Based on Celestial Body Images and Its Method

a technology of celestial body and correction system, applied in the field of heliostat correction, can solve the problems of affecting power generation efficiency, affecting the efficiency of power generation, and the number of heliostats that can be corrected at the same time, and the method with low efficiency usually takes a long time to make the heliostat. , to achieve the effect of ensuring the efficiency of heliostat correction, reducing the possibility of error, and low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The present invention will now be described in detail with reference to the accompanying drawings and embodiments.

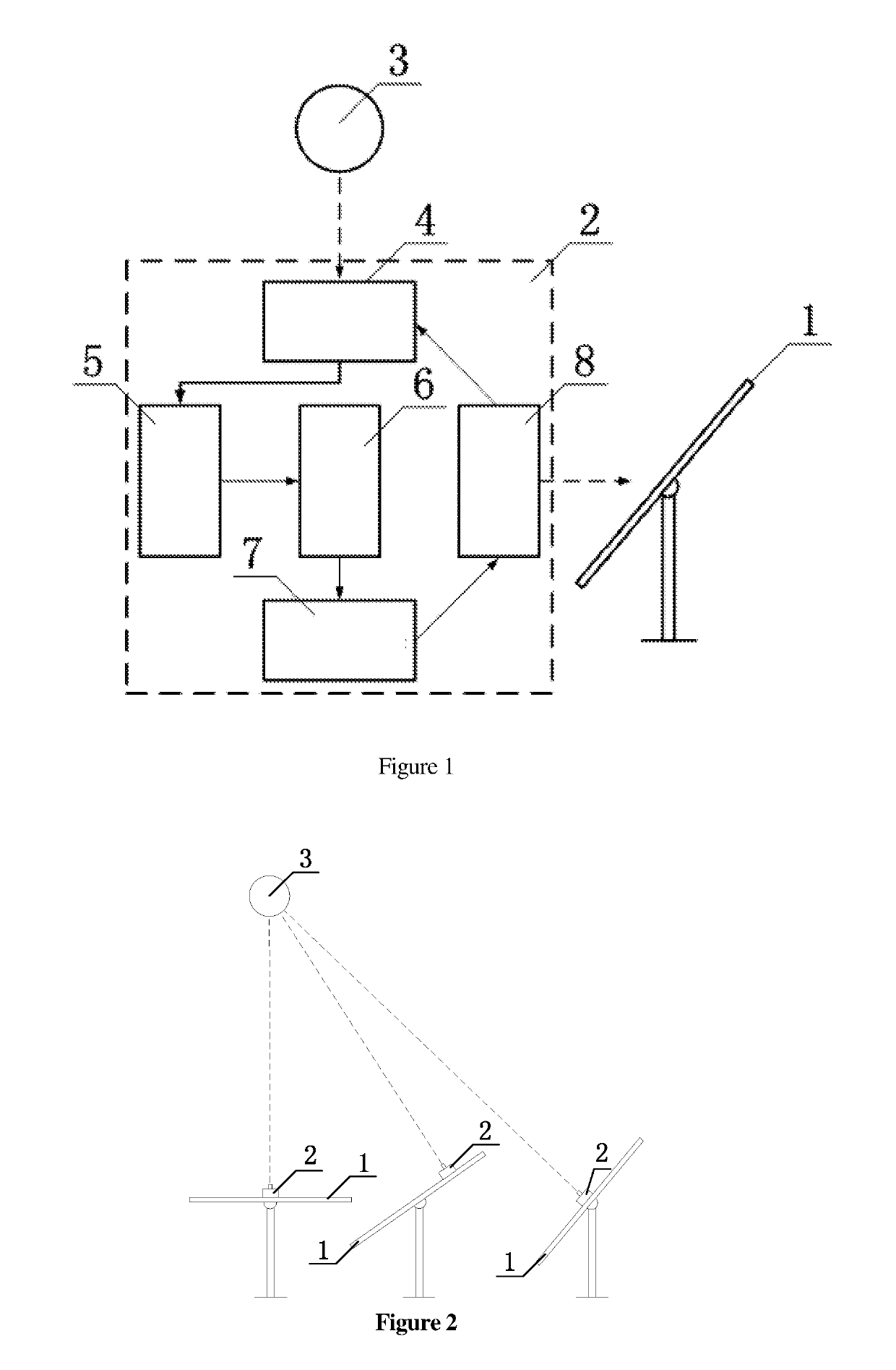

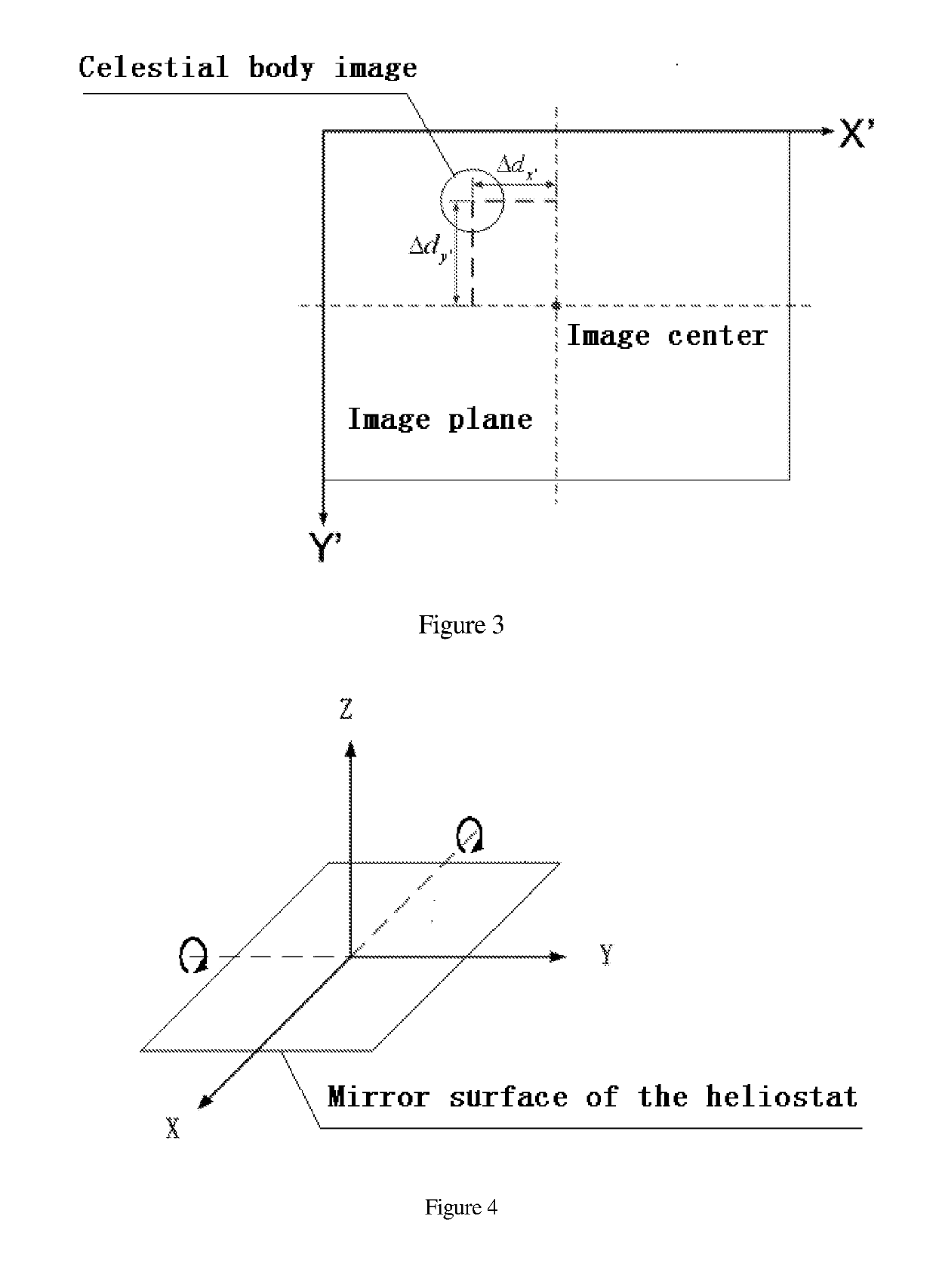

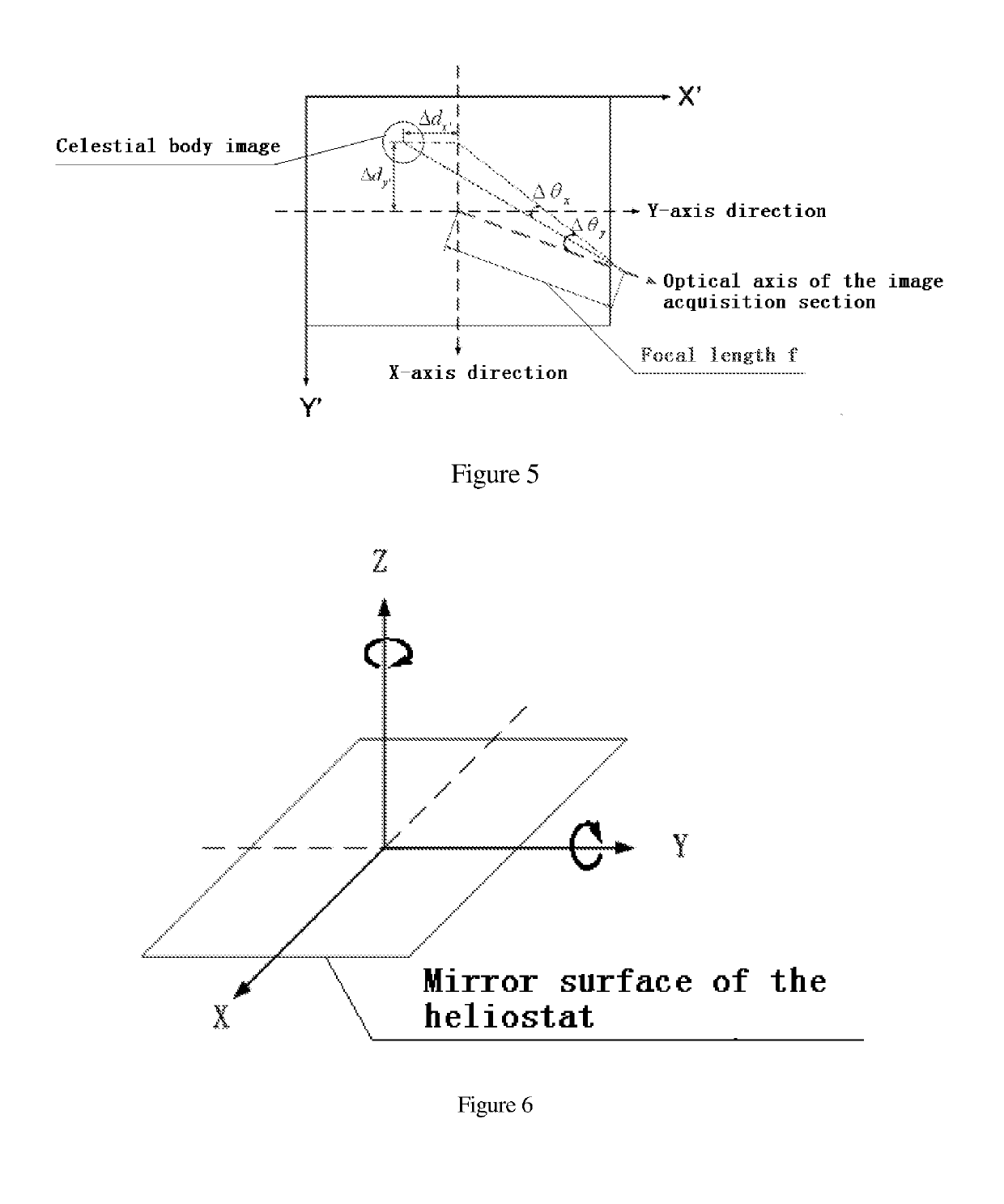

[0049]As shown in FIGS. 1 to 7, a heliostat correction system based on celestial body images comprising a heliostat 1 which is fixed on the rotation axis; the reflecting surface of the heliostat 1 is provided with a heliostat correction system 2; in the present invention, the heliostat correction system 2 comprises an image acquisition module 4, a data analysis module 5, a correction calculation module 6, a data storage module 7 and a communication module 8, and is used for the daily correction of the heliostat 1 in the solar thermal power station. The image acquisition module 4 comprises a light intensity adjusting device (a neutral attenuation sheet or other device capable of adjusting the incident light intensity of a celestial body), an imaging light path (a lens or a pinhole) and a digital image sensor; the image acquisition module 4 is in the same direction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com