System and method for enhanced stereolithography 3D printing

a stereolithography and enhancement technology, applied in the field of systems and methods for enhancing stereolithography 3d printing, can solve the problems of imposing a cost on optical systems, imposing a physical limit to the level of miniaturization that can be achieved, and most sla 3d printers exhibit poor printing precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

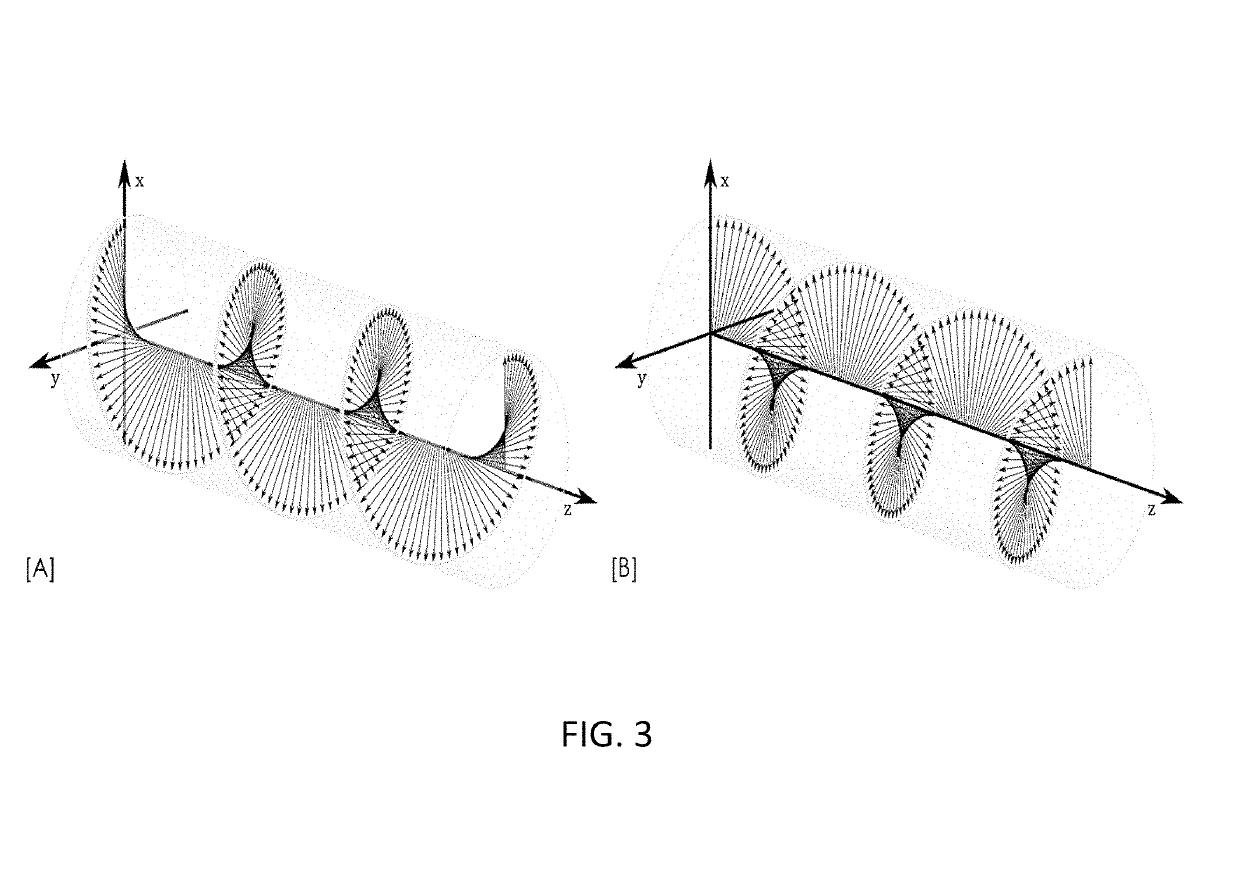

[0082]Referring now specifically to FIG. 6, one representation of the invention is an apparatus [A], [B] comprising a source of UV photons [1], one or more stand alone angular momentum generators [2] configured to deliver UV photons with optimized spin angular momentum (SAM), org orbital angular momentum (OAM), and / or a SAM / OAM [3] combination to target organic or inorganic substance and / or impurity. The angular momentum generator can have different forms [a], [b], [c], and [d].

[0083]Referring now specifically to FIG. 6 [2a] UV photons can acquire optimized OAM with a Spiral Phase Plate made of UV transparent material with refractive index n, having an inhomogeneous thickness, h proportional to the azimuthal angle Φ

h=hsφ2π+h0

[0084]where hs is the step height, and h0 is the base height. When a beam of electromagnetic radiation (Gaussian) with plane phase distribution passes through this OAM generator, an optical vortex charge q is imprinted according to

q=hs(n-n0)λ

[0085]This means tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fixed wavelength | aaaaa | aaaaa |

| fixed wavelength | aaaaa | aaaaa |

| germicidal wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com