Olefin Polymer And Preparation Method Thereof

a technology of olefin polymer and olefin polymer, which is applied in the field of olefin polymer, can solve the problems of increasing the use of stretch films, reducing the mechanical properties of conventional lldpe, and poor processability of lldpe for blown films, so as to achieve excellent film processability and physical properties, and excellent mechanical strength. , the effect of high processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

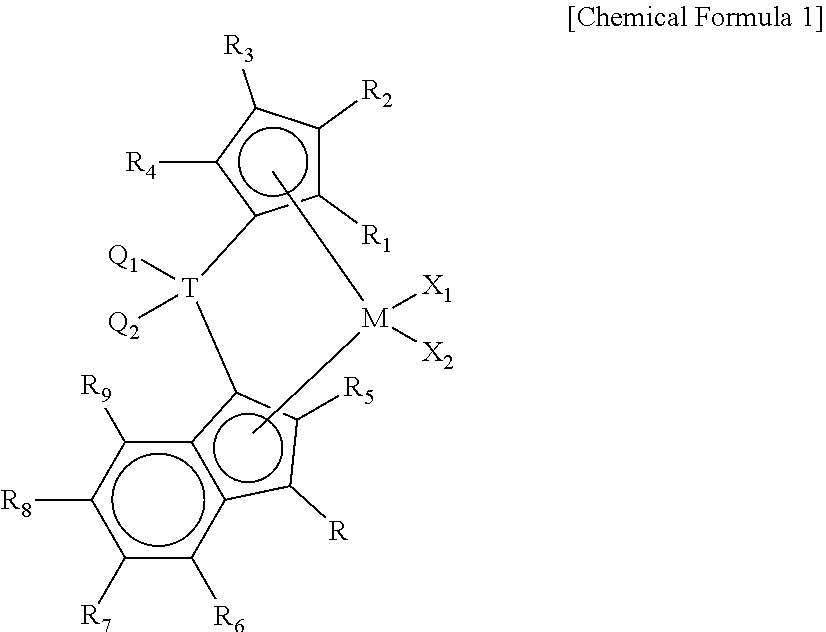

tion Metal Compound (Metallocene Catalyst Precursor A)

[0172]

[0173]Tetramethylcyclopentadiene (TMCP, 6.0 mL, 40 mmol) was dissolved in THF (60 mL) in a dried 250 mL Schlenk flask and then cooled to −78° C. Then n-BuLi (2.5 M, 17 mL, 42 mmol) was slowly added dropwise to the above solution, and the mixture was stirred overnight at room temperature.

[0174]On the other hand, dichlorodimethylsilane (4.8 mL, 40 mmol) was dissolved in n-hexane in another 250 mL Schlenk flask and then cooled to −78° C. Then, the TMCP-lithiation solution previously prepared was slowly added to this solution, and the mixture was stirred overnight at room temperature. Thereafter, the resulting solution was subjected to reduced pressure to remove solvent. The resulting solid was dissolved in toluene and filtered to remove residual LiCl, thereby obtaining chlorodimethyl(2,3,4,5-tetramethylcyclopenta-2,4-dien-1-yl) silane as an intermediate (yellow liquid, 7.0 g, 33 mmol, 83% yield).

[0175]1H NMR (500 MHz, CDCl3): ...

synthesis example 2

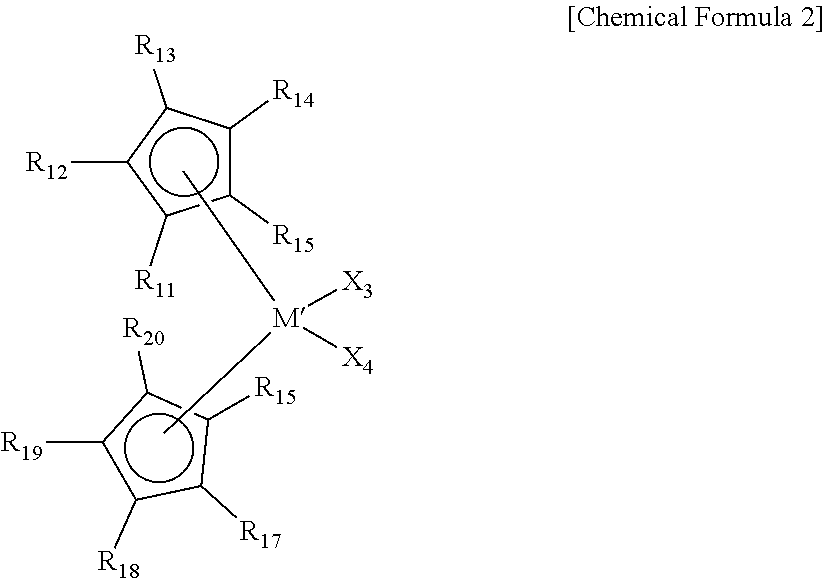

tion Metal Compound (Metallocene Catalyst Precursor B)

[0180]

[0181]The metallocene compound (B) having the above structural formula was prepared (purchased from Strem Corporation, Cas Number 12148-49-1).

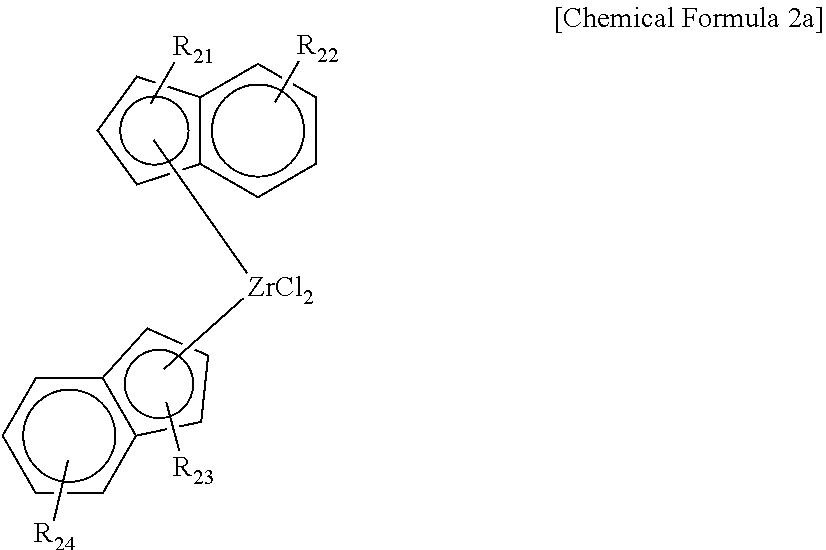

synthesis example 3

tion Metal Compound (Metallocene Catalyst Precursor C)

[0182]Tetramethylcyclopentadiene (TMCP, 6.0 mL, 40 mmol) was dissolved in THF (60 mL) in a dried 250 mL Schlenk flask and then cooled to −78° C. Then n-BuLi (2.5 M, 17 mL, 42 mmol) was slowly added dropwise to the above solution, and the mixture was stirred overnight at room temperature.

[0183]On the other hand, dichlorodimethylsilane (4.8 mL, 40 mmol) was dissolved in n-hexane in another 250 mL Schlenk flask and then cooled to −78° C. Then, the TMCP-lithiation solution previously prepared was slowly added to this solution, and the mixture was stirred overnight at room temperature.

[0184]Thereafter, the resulting solution was subjected to reduced pressure to remove solvent. The resulting solid was dissolved in toluene and filtered to remove residual LiCl, thereby obtaining an intermediate (yellow liquid, 7.0 g, 33 mmol, 83% yield).

[0185]1H NMR (500 MHz, CDCl3): 0.24 (6H, s), 1.82 (6H, s), 1.98 (6H, s), 3.08 (1H, s).

[0186]Indene (0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com