Wet-process powder forming preparation method of agilawood-containing tobacco auxiliary material and tobacco product

A technology of powder molding and agarwood, applied in tobacco, tobacco processing, tobacco preparation, etc., to improve the sensory quality of cigarettes and reduce sensory stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

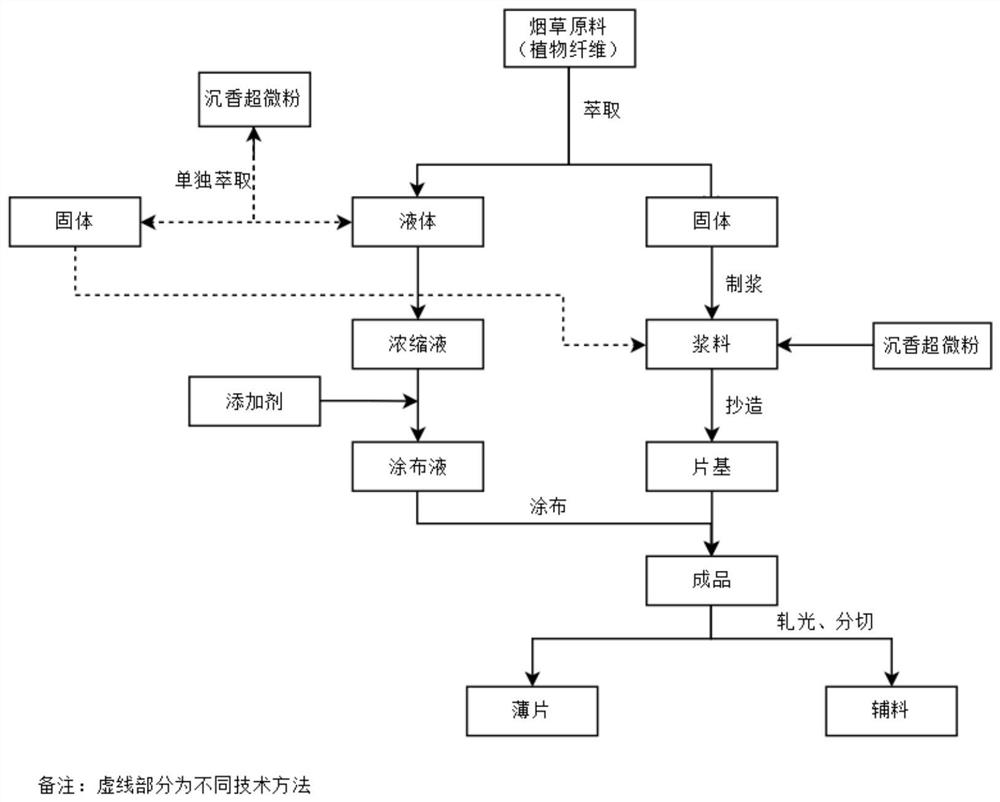

[0080] see figure 1 , Concretely, the preparation method of the adjuvant for tobacco-containing cigarettes provided by the application comprises the following steps:

[0081] (1) Preparation of ultrafine powder: use an oven to dry the agarwood to a moisture content of about 10% under the condition of 40°C, and use the ultrafine pulverizing equipment to prepare the agarwood raw material pretreated in step (1) into a 20-800 m agarwood ultrafine powder ;

[0082] (2) extraction: carry out solid-liquid separation after extracting the agarwood ultrafine powder of step (1) and tobacco raw material respectively, obtain solid (agarwood ultrafine powder extract residue) and filtrate; or carry out solid-liquid separation after the tobacco raw material is extracted, Agarwood ultrafine powder does not participate in extraction;

[0083] (3) pulping and making: use a beating machine to pulp tobacco raw materials and plant fibers to obtain a slurry with a set beating degree; further add t...

Embodiment 1

[0088] Example 1: Preparation of tobacco sheet sample 1 containing excipients for cigarettes

[0089] Material selection: weigh 20 parts by weight of agarwood raw materials, 15 parts by weight of softwood pulp, and 65 parts by weight of tobacco raw materials as raw materials. In the raw materials of agarwood, the hooking and shoveling are mixed according to the mass ratio of 1:1.

[0090] Preparation of ultrafine powder: use ultrafine pulverization equipment to prepare the raw material of agarwood into D 50 =50 mesh agarwood superfine powder;

[0091] Extraction: The raw materials (tobacco raw materials, plant fibers) and water were mixed at a weight ratio of 1:5, and the mixture was extracted at 50° C. for 1 h to obtain a solid part and a liquid part.

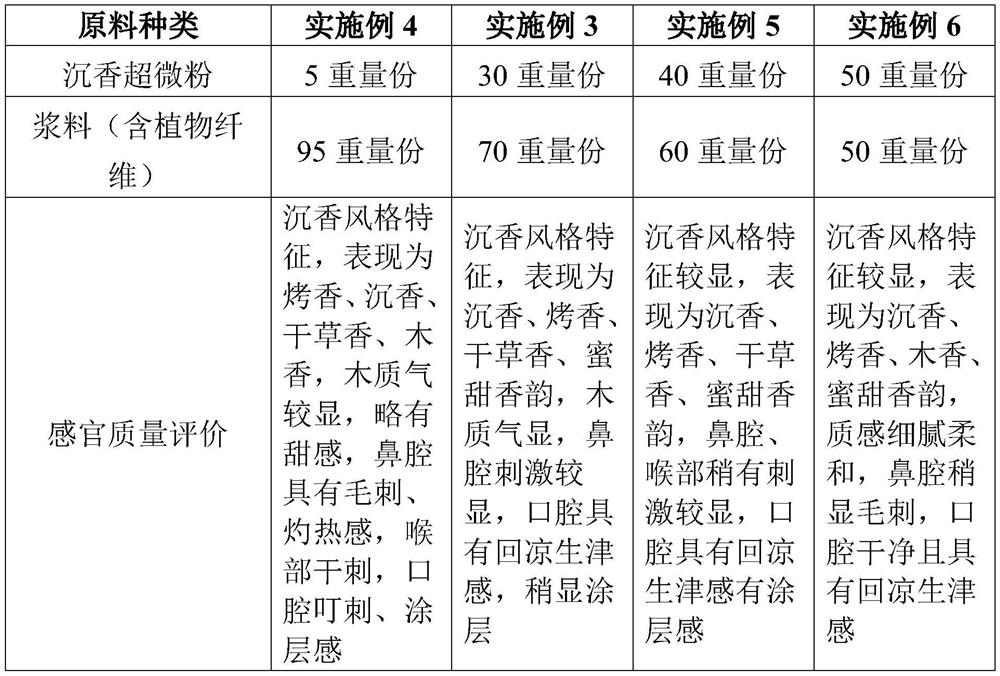

[0092] Pulping and papermaking: the solid part is pulped with a beating degree of 30°SR to obtain a slurry, and the agarwood ultrafine powder is added to the slurry with 5 parts by dry weight, and the absolute dry weight of ...

Embodiment 2

[0095] Example 2: Preparation of tobacco sheet sample 2 containing excipients for cigarettes

[0096] Material selection: weigh 20 parts by weight of agarwood raw materials, 15 parts by weight of hardwood pulp, and 65 parts by weight of tobacco raw materials as raw materials. The raw materials of agarwood are shoveled and hooked and mixed in a mass ratio of 5:1.

[0097] Preparation of ultrafine powder: use ultrafine pulverization equipment to prepare the raw material of agarwood into D 50 =500 mesh agarwood superfine powder;

[0098] Extraction: Mix the raw materials (tobacco raw materials, plant fibers) and water according to the weight ratio of 1:20, and extract the mixture at 90° C. for 5 hours to obtain a solid part and a liquid part.

[0099] Pulping and papermaking: the solid part is pulped with a beating degree of 65°SR to obtain a slurry, and the agarwood ultrafine powder is added to the slurry with 50 parts by dry weight, and the absolute dry weight of the slurry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com