Multi-pixel x-ray source with tungsten-diamond transmission target

a technology of tungsten-diamond and x-ray source, which is applied in the direction of x-ray tube target materials, instruments, stochastic cad, etc., can solve the problem of high inefficiency of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

n of the Multi-Pixel Thermionic Emission X-Ray Source (MPTEX)

[0095]This Example describes the development of a multi-pixel thermionic emission x-ray source (MPTEX) prototype, and the evaluation of the performance of the prototype.

Methods and Materials

[0096]Multi-Pixel Thermionic Emission X-Ray Source (MPTEX):

[0097]An MPTEX source prototype for TBCT applications is developed. The tube is made of aluminum body with ConFlat flanges. Water cooling pipes are embedded in the aluminum tube body for fast heat removal. The anode is made from a graphite bar brazed with a 5 mm thick tungsten target. FIGS. 14A and 14B show the MPTEX prototype and its functional diagram. The tube can contain up to 48 thermionic cathodes in a 4 mm spatial spacing and each cathode may produce the same numbers of focal spots. Both oxide coated and dispenser cathodes that can produce 100 mA and 500 mA cathode current respectively are evaluated. The tube is able to operate at 100 kVp limited by the anode high voltage...

example 2

on of a W-PG Laminate Anode on an APG Base

[0102]This Example describes the fabrication of APG anode modules with W-APG laminate targets.

[0103]APG Base:

[0104]FIG. 16A shows the cross section of an MPTEX source and FIG. 16B shows the anode module of the MPTEX source. The anode is about 25 cm long made from a graphite bar brazed with a 5 mm thick tungsten target. Because of the symmetric temperature distribution in tube length (z) direction, the heat flows primarily in the cross sectional plane. Thus, the a-b plane of APG with large thermal conductivity needs to be aligned parallel to the tube cross section. The a-b plane of commercial APG plates synthesized with chemical vapor deposition (CVD) techniques is perpendicular to its thickness. Commercial APG plates can be purchased and machined into the dog-bone shape as shown in FIG. 16B. The APG plates may be coated with W-PG laminate target and then stacked together with the x-y planes of APG plates along the cross sectional plane (the ...

example 3

n and Optimization of W-PG Laminate Target

[0111]This Example describes the development of a technique to evaluate W-PG target and optimize its performance.

[0112]Various parameters, such as number of W-PG layers, thickness of each PG and W layers, annealing temperature and time need to be determined. The design is first guided by numerical simulation and then optimized through experimental studies.

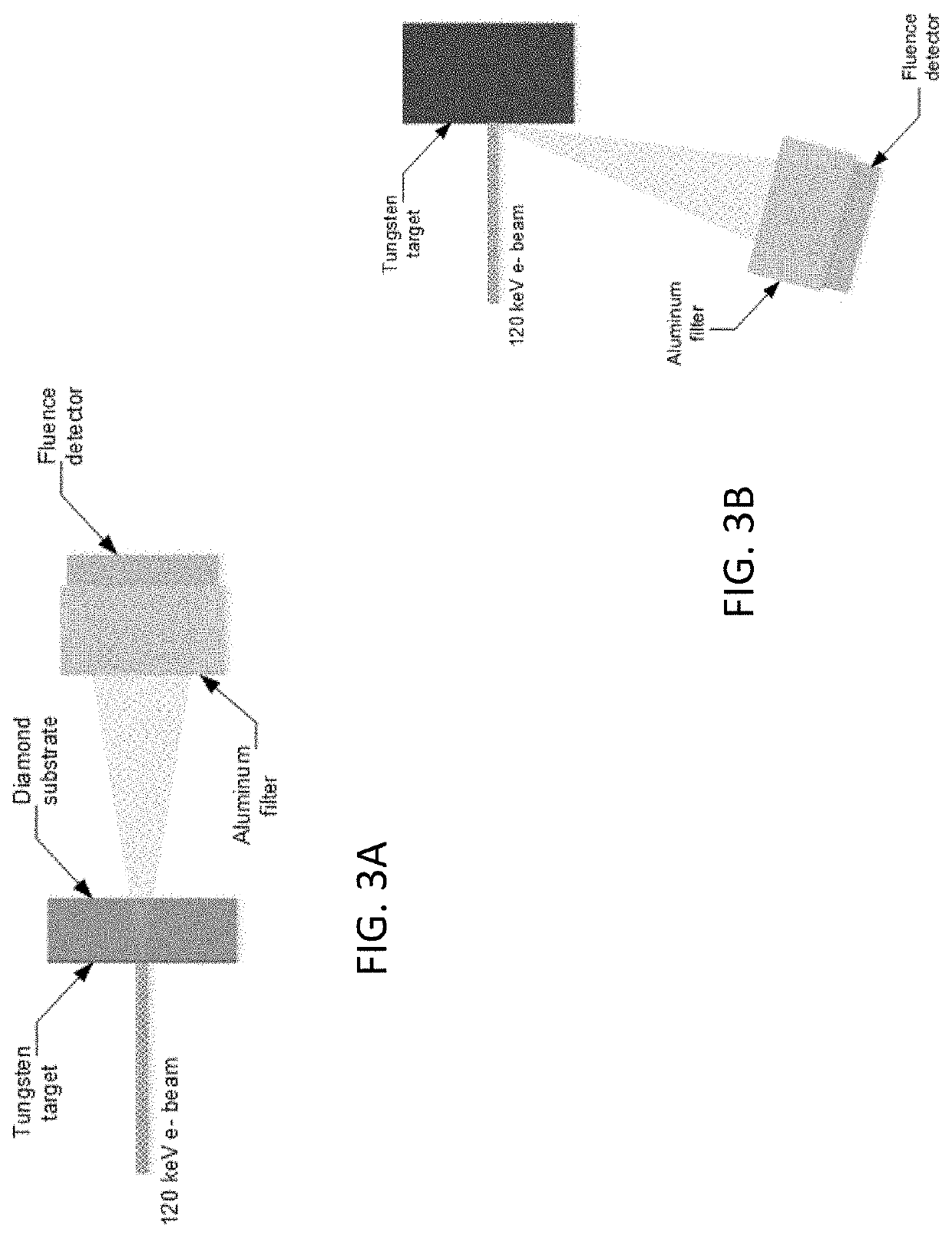

[0113]Optimization of W-PG Laminate Target Via Monte Carlo Simulation and FEA Method:

[0114]The Continuous Slow Down Approximation (CSDA) range of a 120 keV beam is about 15 μm. Thus, a total thickness of 10-15 μm for a W target is sufficient. The heat should be evenly divided to different W layers to achieve the best result. Monte Carlo (MC) simulation is used to determine the thicknesses of PG and W layers such that the power transferred to each W layer is approximate the same. The energy lost to the APG layers should be as low as possible. On the other hand, thinner APG conducts heat slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com