Silicon carbide semiconductor device, power converter, and method of manufacturing silicon carbide semiconductor device

a technology of silicon carbide and semiconductor devices, which is applied in the direction of semiconductor devices, electrical devices, transistors, etc., can solve the problems of increasing the on resistance of the mosfet, causing more damage, and reducing the occurrence of insulation breakdown. , to achieve the effect of reducing the occurrence of insulation breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

[0034](Configuration)

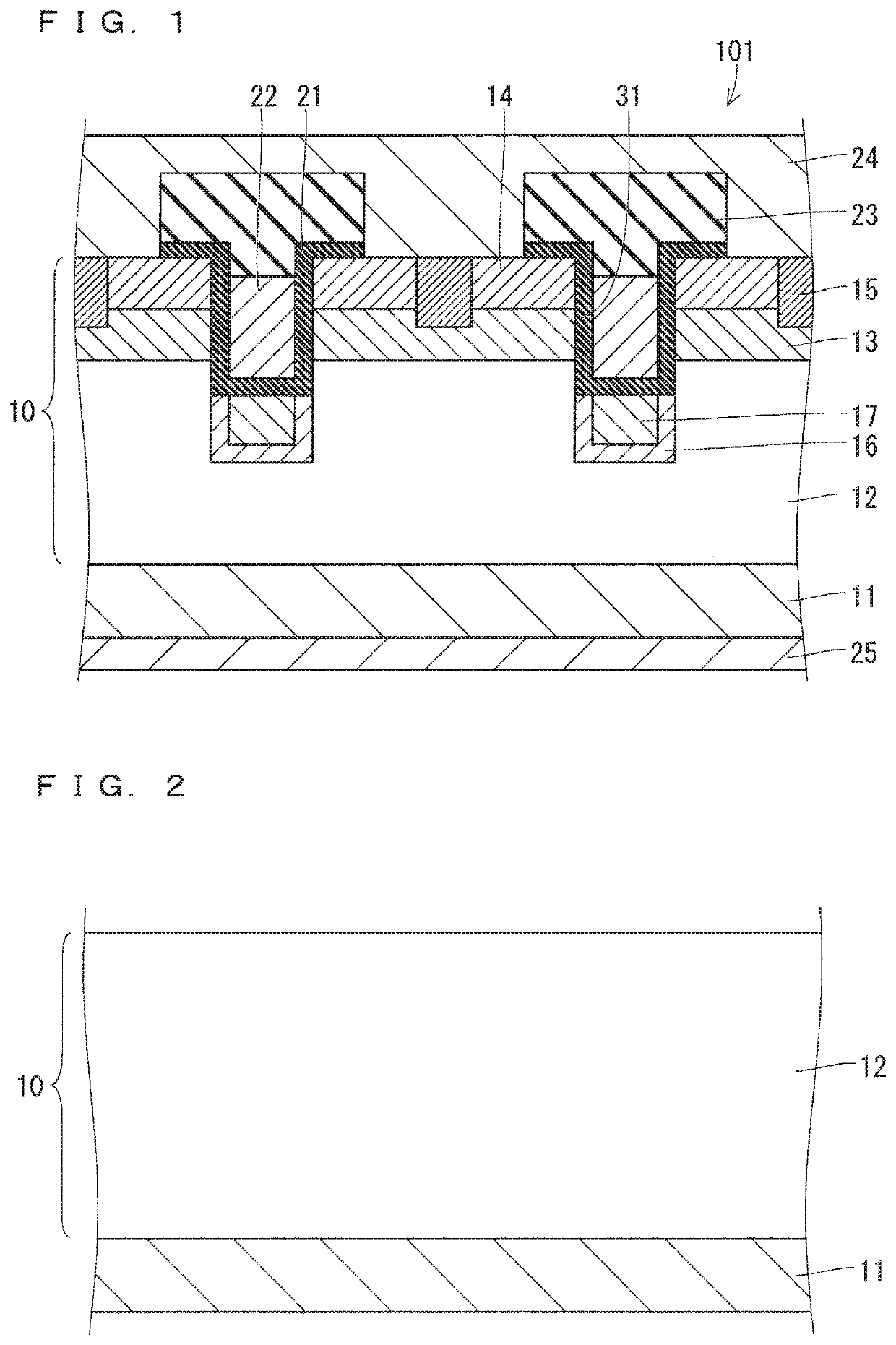

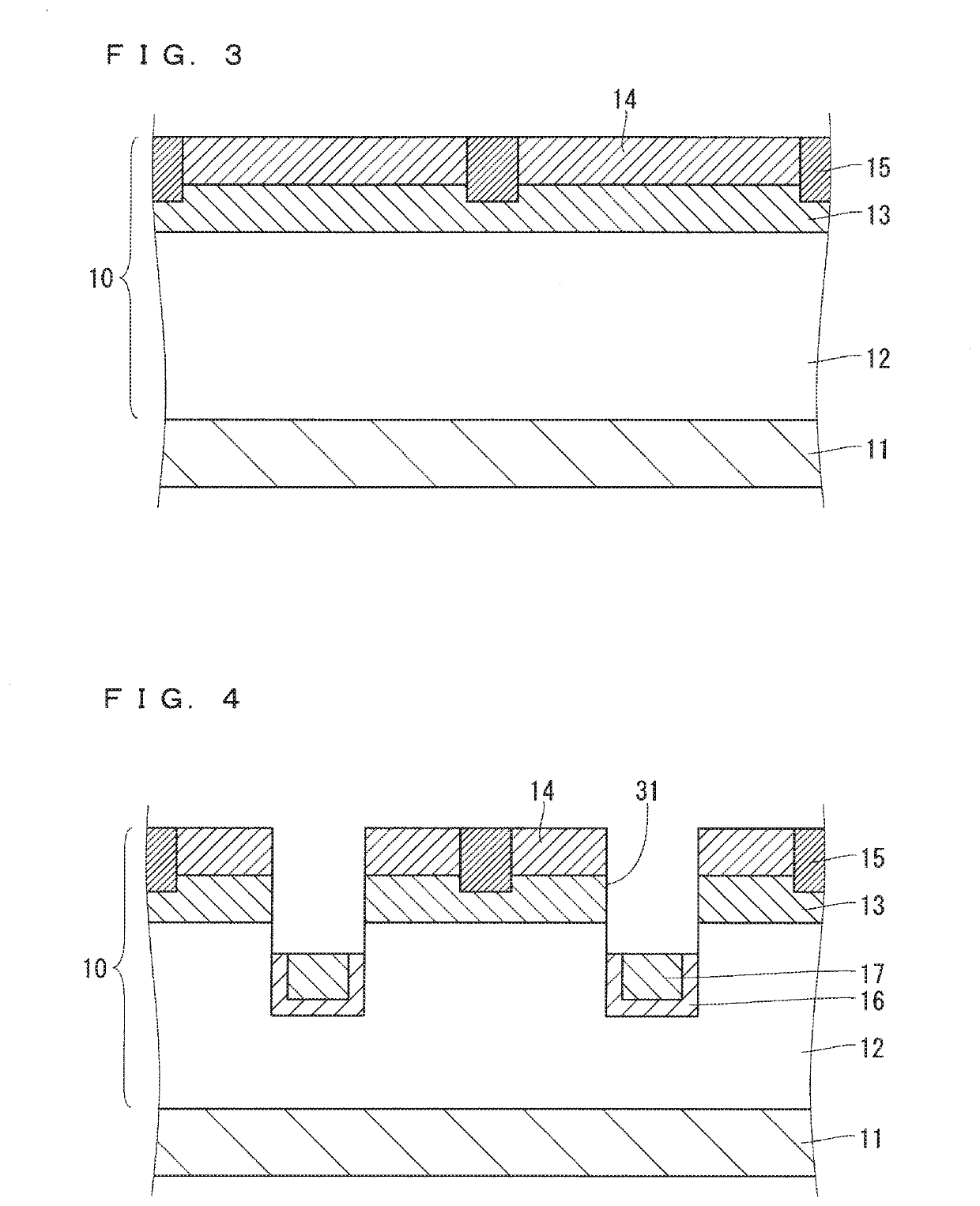

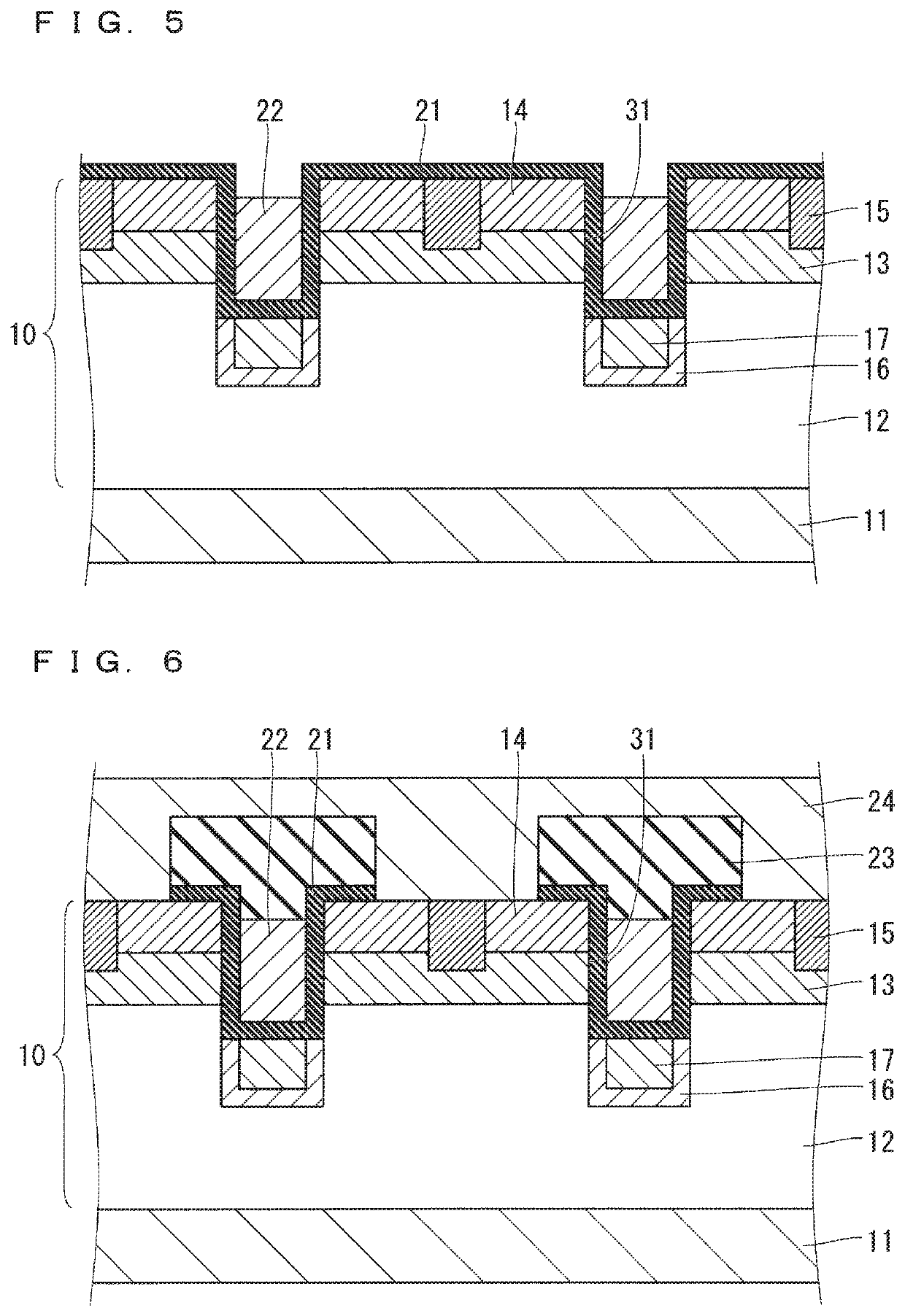

[0035]FIG. 1 is a partial sectional view schematically showing the configuration of an MOSFET 101 (silicon carbide semiconductor device) according to a first preferred embodiment. The MOSFET 101 includes an SiC substrate 11 (silicon carbide substrate), an epitaxial layer 10 (semiconductor layer) provided on one surface (in FIG. 1, upper surface) of the SiC substrate 11, a gate insulating film 21, a gate electrode 22, an interlayer insulating film 23, a source electrode 24, and a drain electrode 25. The epitaxial layer 10 includes a drift layer 12, a well region 13, a source region 14, a well contact region 15, an electric field relaxation region 16, and a surge relaxation region 17. The epitaxial layer 10 is preferably made of SiC.

[0036]In the first preferred embodiment, the SiC substrate 11 has the same conductivity type as the drift layer 12. The drift layer 12 has an n-type (first conductivity type) and is provided on the SiC substrate 11. The drift layer 12 ...

second preferred embodiment

[0068]FIG. 11 schematically shows the configuration of an MOSFET 103 (silicon carbide semiconductor device) according to a second preferred embodiment and is a partial sectional view taken along a line XI-XI in FIG. 12. FIG. 12 is a partial sectional view taken along a line XII-XII in FIG. 11. The illustration of the source electrode 24 is omitted from FIG. 11.

[0069]Referring to FIG. 11, in the second preferred embodiment, multiple cell structures of the MOSFET 103 are aligned in an in-plane direction. In FIG. 11, the gate electrode 22 has a lattice pattern in a planar layout. However, this is not the only planar layout of the gate electrode 22 but the gate electrode 22 may also have a stripe pattern, example.

[0070]Referring to FIG. 12, the right region and the left region in FIG. 12 have configurations similar to the configuration in FIG. 1 (first preferred embodiment). Meanwhile, in the central part of FIG. 12, a source trench 32 is provided in the epitaxial layer 10.

[0071]The sou...

third preferred embodiment

[0077](Configuration)

[0078]FIG. 13 schematically shows the configuration of an MOSFET 104 (silicon carbide semiconductor device) according to a third preferred embodiment and is a partial sectional view taken along a line XIII-XIII in each of FIGS. 14 and 15. FIGS. 14 and 15 are partial sectional views taken along a line XIV-XIV and a line XV-XV respectively in FIG. 13.

[0079]Referring to FIG. 13, in the third preferred embodiment, multiple cell structures of the MOSFET 104 are aligned in an in-plane direction. In FIG. 13, the planar layout of the gate electrode 22, in other words, the planar layout of the gate trench 31 is a stripe pattern.

[0080]Referring to FIG. 14, the MOSFET 104 includes a part where a cross-sectional configuration is similar to the cross-sectional configuration of the MOSFET 101 (FIG. 1). At least this part has the function of forming a channel in the MOSFET 104.

[0081]Referring to FIG. 15, the MOSFET 104 includes a part where a cross-sectional configuration diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com