Permeable membrane microchannel heat sinks and methods of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

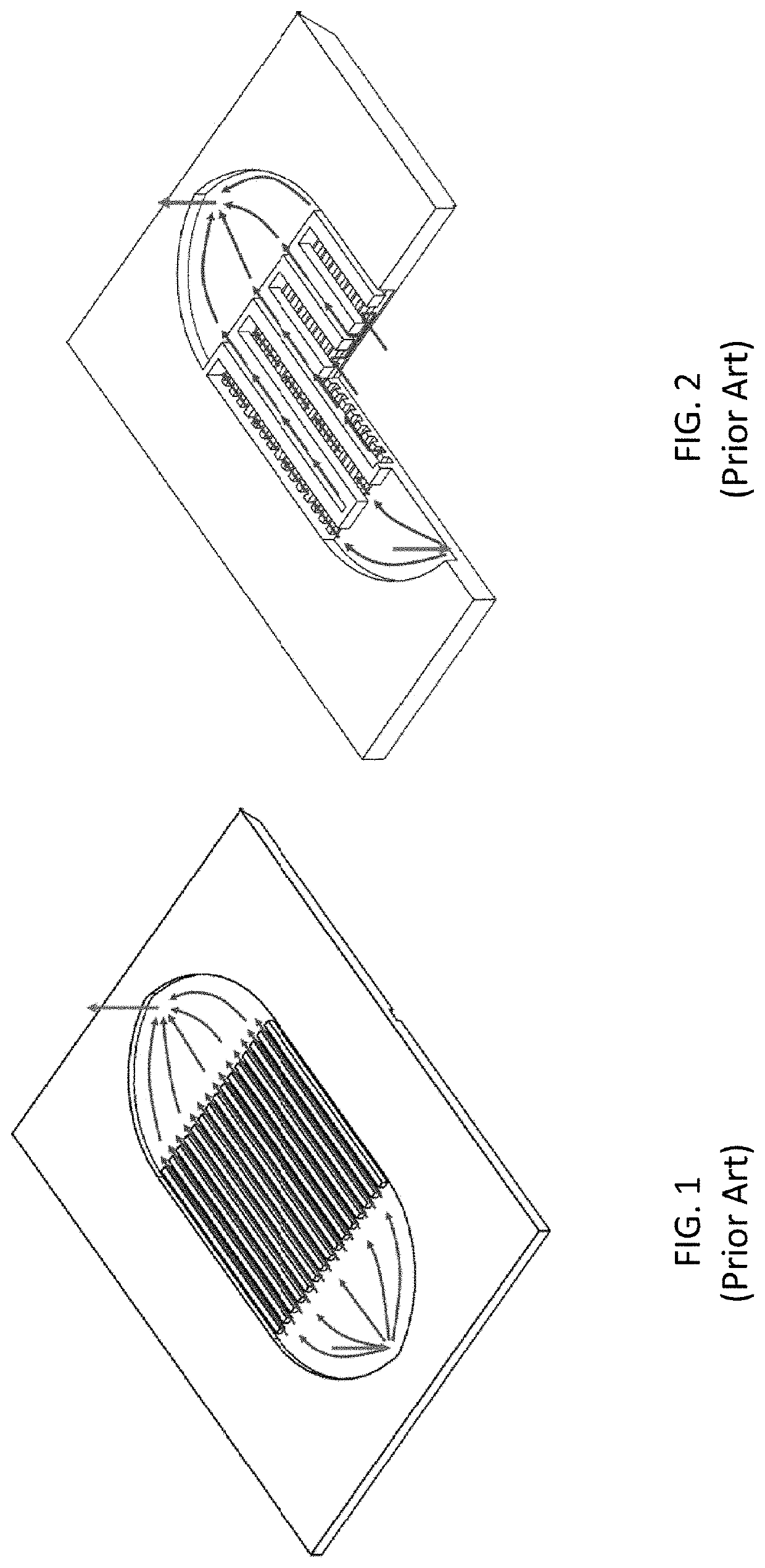

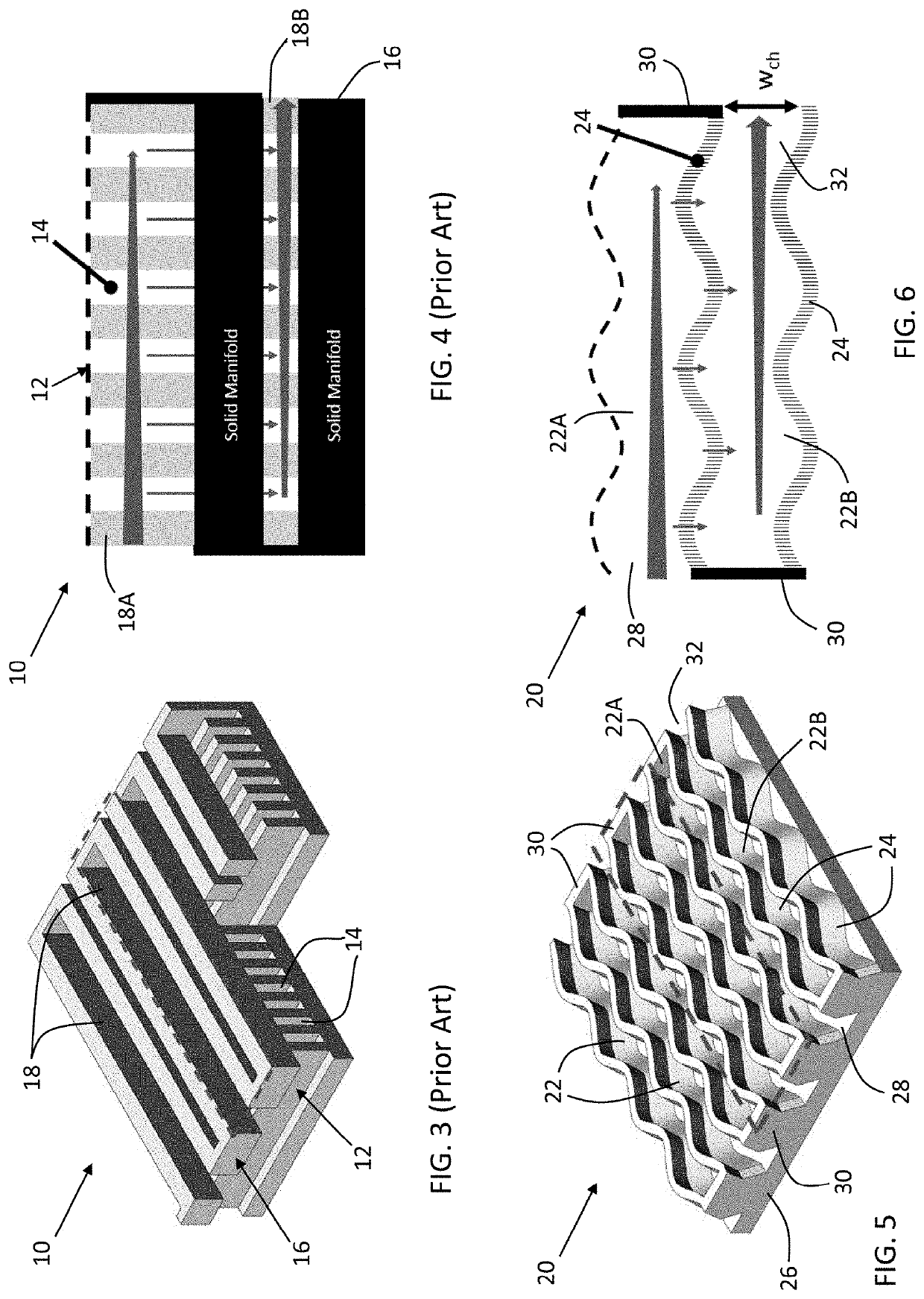

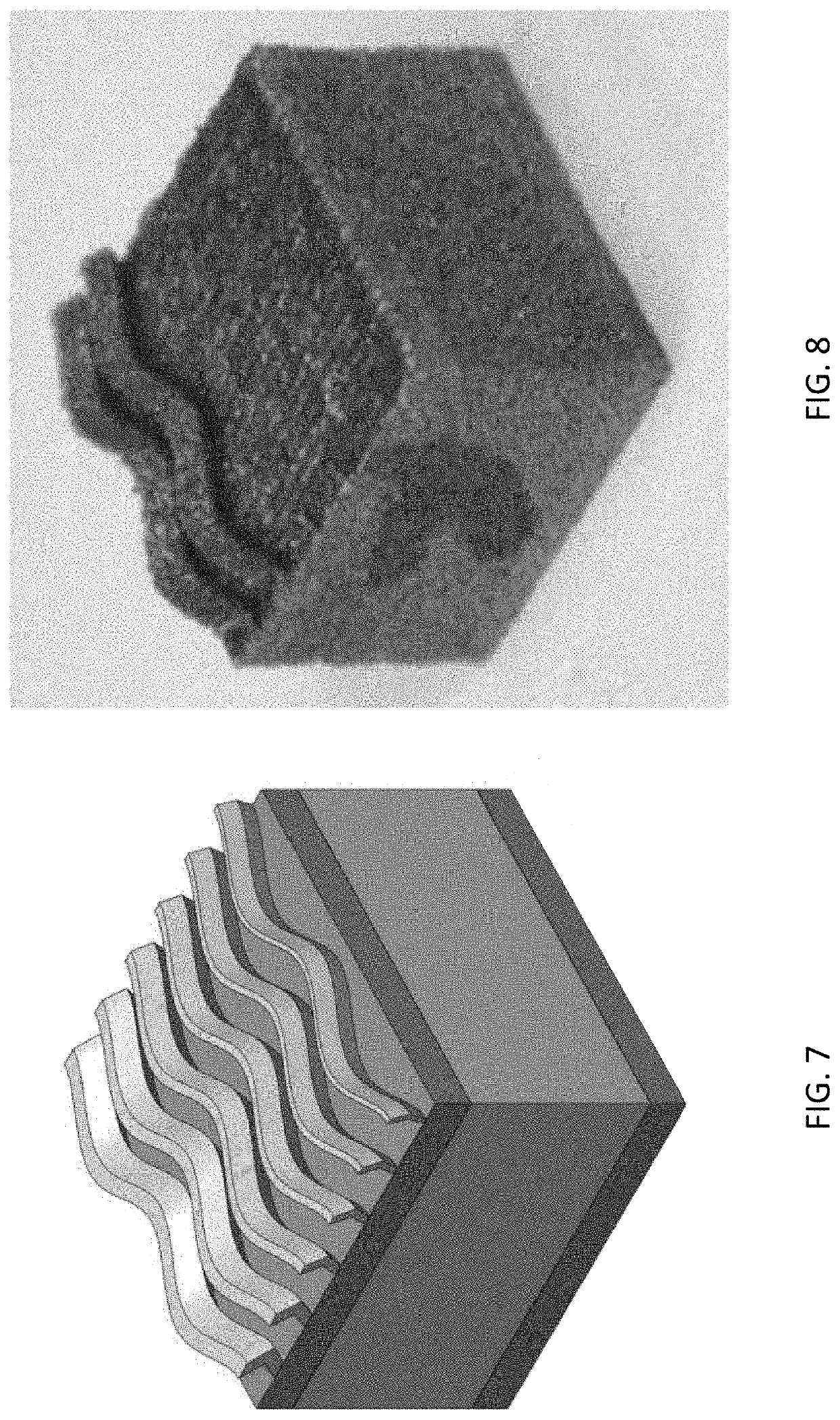

[0025]The following describes the development, fabrication, and evaluation of heat sinks that incorporate complex non-linear three-dimensional (3D) structures comprising one or more porous walls (membranes) as their primary heat transfer surface(s), whereby the heat sinks contain internal porosity that creates fluid flow paths through the membranes to increase the area available for heat transfer, and the membranes are sufficiently thin to reduce pressure drop in comparison to a manifold microchannel heat sink. The internal porosity-containing heat sinks, referred to herein as permeable membrane microchannel (PMM) heat sinks, were fabricated using direct metal laser sintering (DMLS) of an aluminum alloy (AlSi10Mg), though it should be understood that heat sinks formed by other fabrication techniques and materials are also within the scope of the present invention.

[0026]Investigations discussed below benchmarked PMM heat sinks against a manifold microchannel (MMC) heat sink both expe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com