Experimental test method for subcritical propagation rate of rock fractures based on triaxial stress - strain curve

a triaxial stress strain curve and experimental test method technology, applied in the field of rock mechanics research, can solve the problems of restricting the study of subcritical fracture propagation under high effective stress, and achieve the effect of simplifying experimental data acquisition and more accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

[0095]Cores was selected and taken from deep shale formation in a block in Sichuan Basin to conduct experiments based on the detailed implementation of the above steps. The specific process is described as follows.

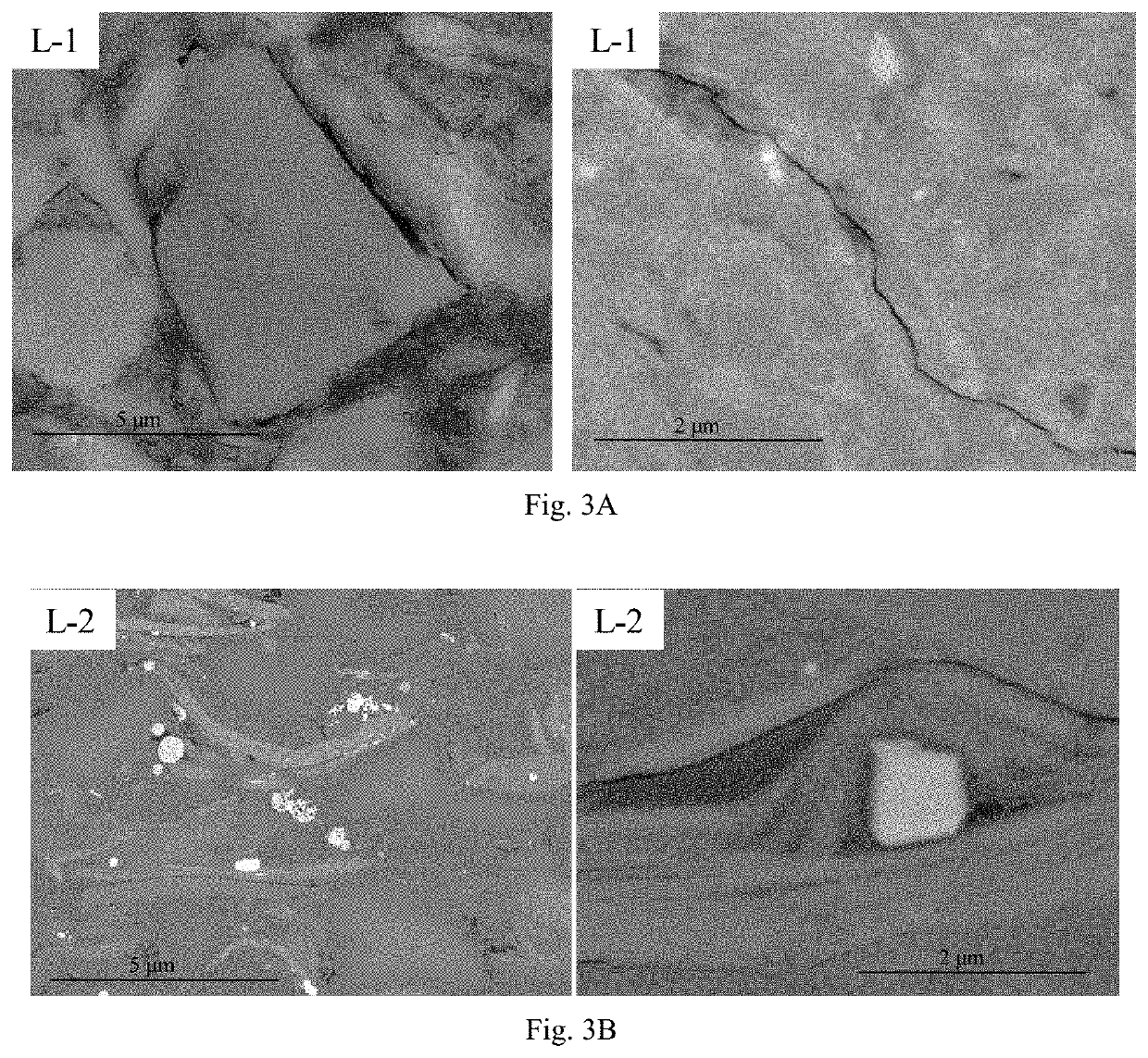

[0096]Step 1: Select and take cores from deep shale formation in a block in Sichuan Basin, drill and prepare test cores L-1 and L-2 (Table 1) according to the rock sample preparation method stated in SYT5358-2010; the cores had no visible fractures and were dried at 60° C. to constant weight.

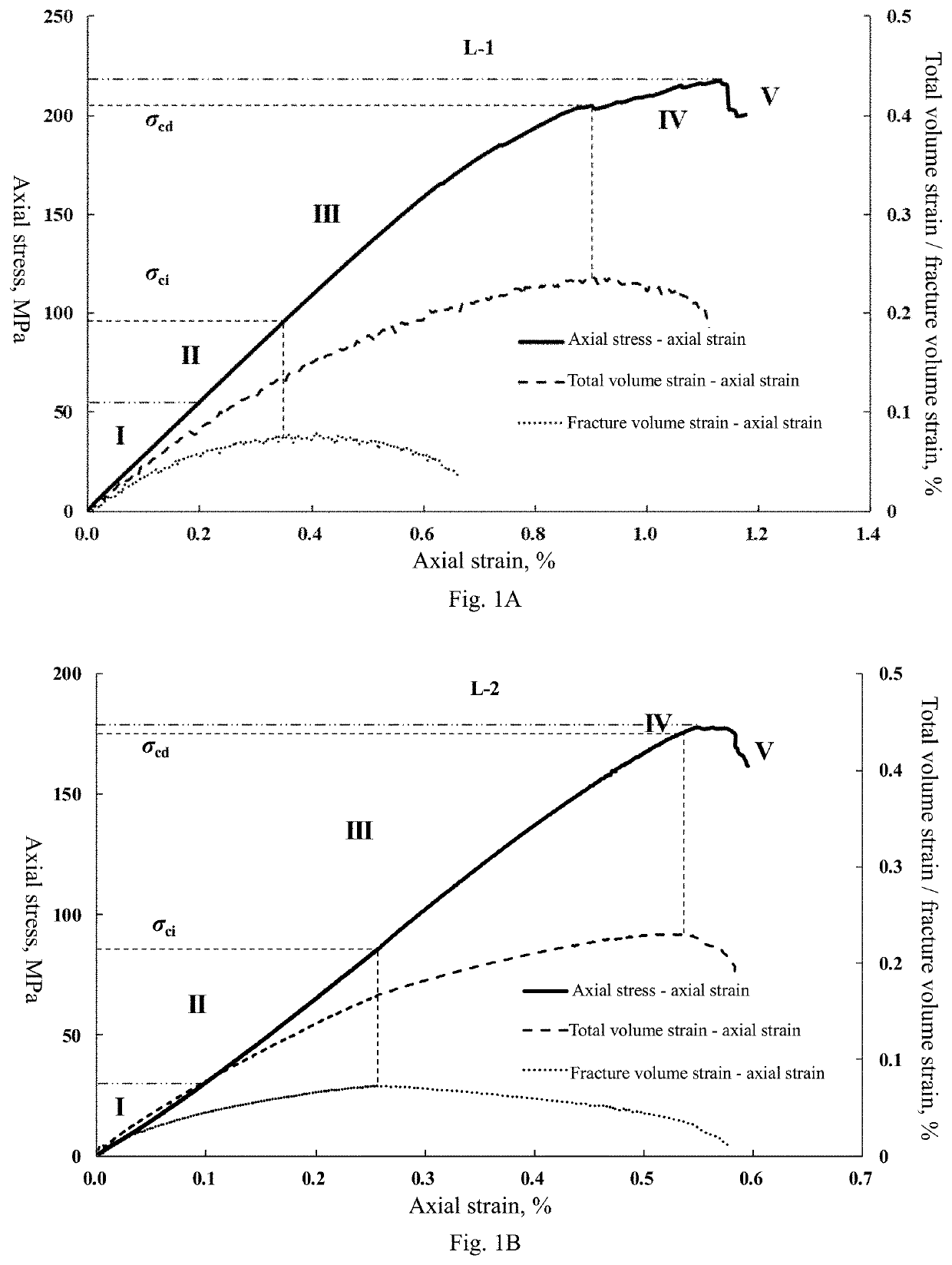

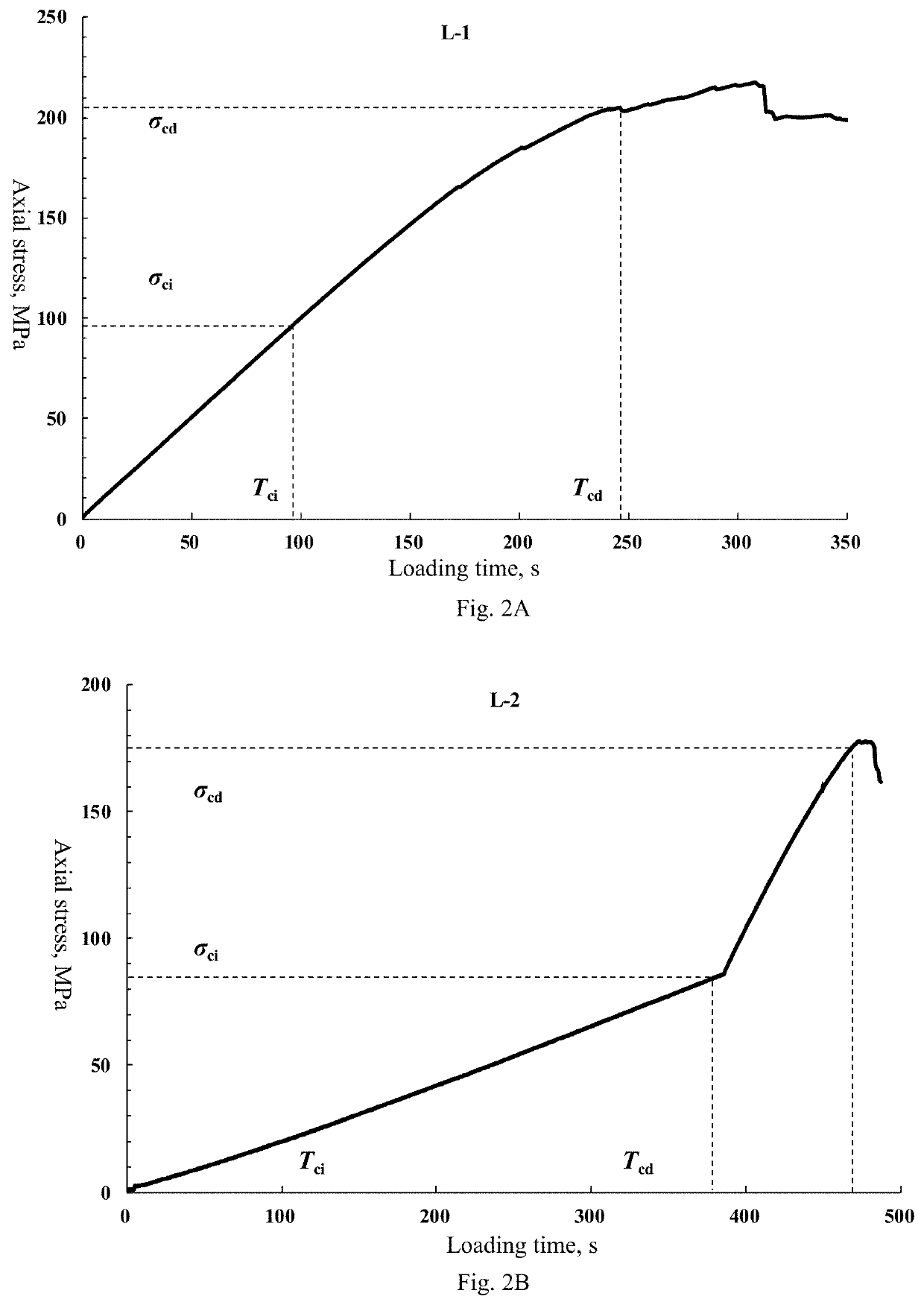

[0097]Step 2: Put the dried core into the GCTS triaxial rock mechanics test system, apply constant confining pressure (radial stress) of 30 MPa to the core, and apply axial stress in the axial direction after the confining pressure is stable; in order to satisfy the quasi-static loading requirement in test, the axial loading rate is only 0.005 mm / s; record the experimental parameters such as axial stress, strain and corresponding loading time of the core throughout the loading test unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com