Automatic inspection of printing plates or cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Before describing some embodiments of the present invention in detail, two specific, non-limiting examples of a system useful in the performance of the method of the present invention will be described, one useful in the manufacture of offset plates and the other in the manufacture of gravure cylinders.

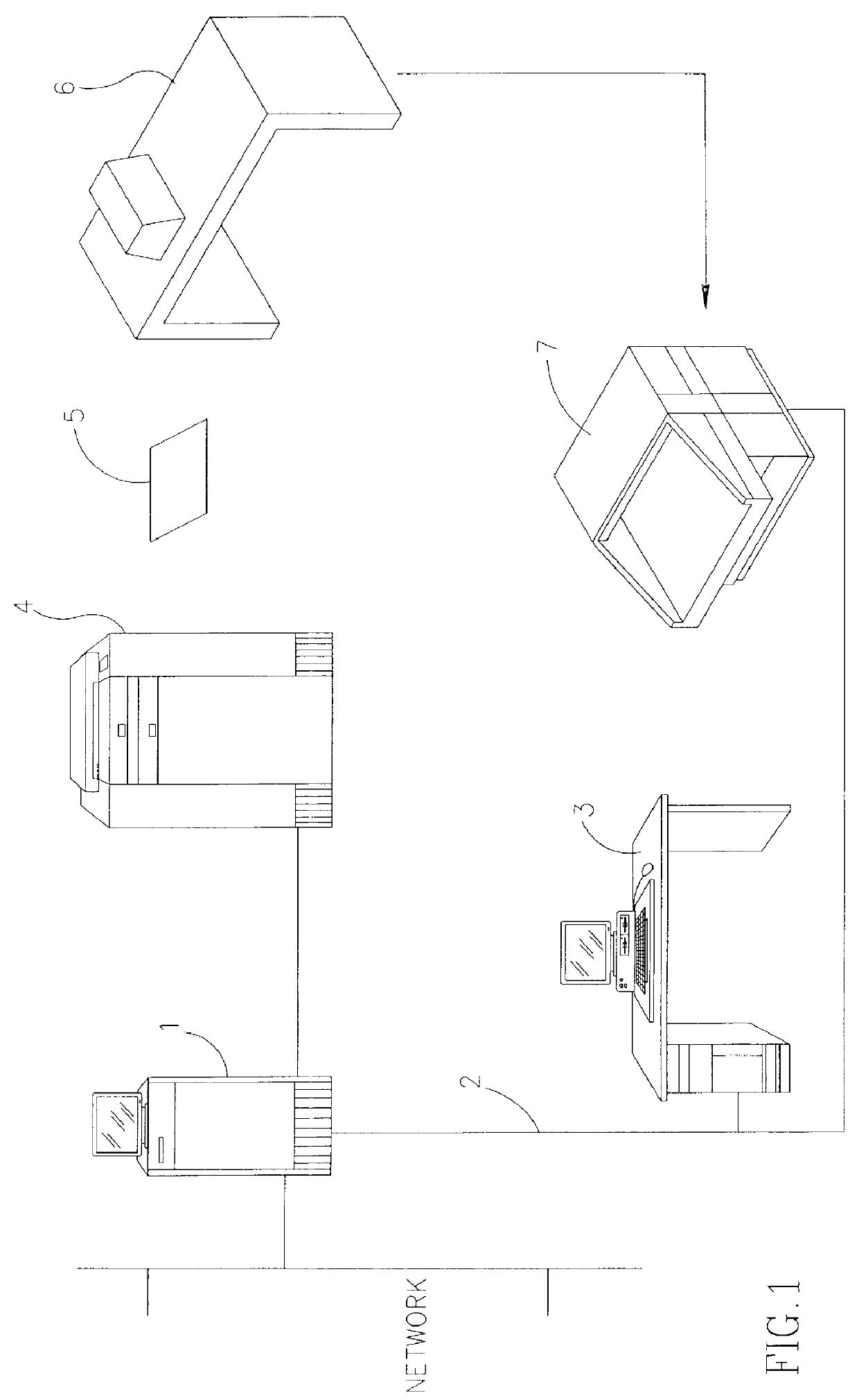

Attention is directed to FIG. 1 showing a schematic illustration of a system useful in an embodiment of the invention which serves for the manufacturing of offset plates. The system comprises a computer 1 such as micro-Whisper / I.TM. computer, commercially available from Scitex Corporation, Herzlia, Israel, interlinked by means of communication network 2 to workstation 3 such as a Prisma.TM. or Star PS.TM., commercially available from Scitex Corporation, Herzlia, Israel. Computer 1 is also linked to image setter 4 such as Dolev 200.TM. commercially available from Scitex Corporation, Herzlia, Israel.

In operation, a reference digital representation of an imposed printing plate, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com