Electrochromic media for producing a preselected color

a technology of electrochromic media and preselected color, which is applied in the field of electrochromic media for producing preselected color, can solve the problems of inability to acceptably produce gray shades, inability to change the light reflectance of mirrors, and numerous other shades, and achieves the effect of contributing to the spectrum of mediums and higher relative proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

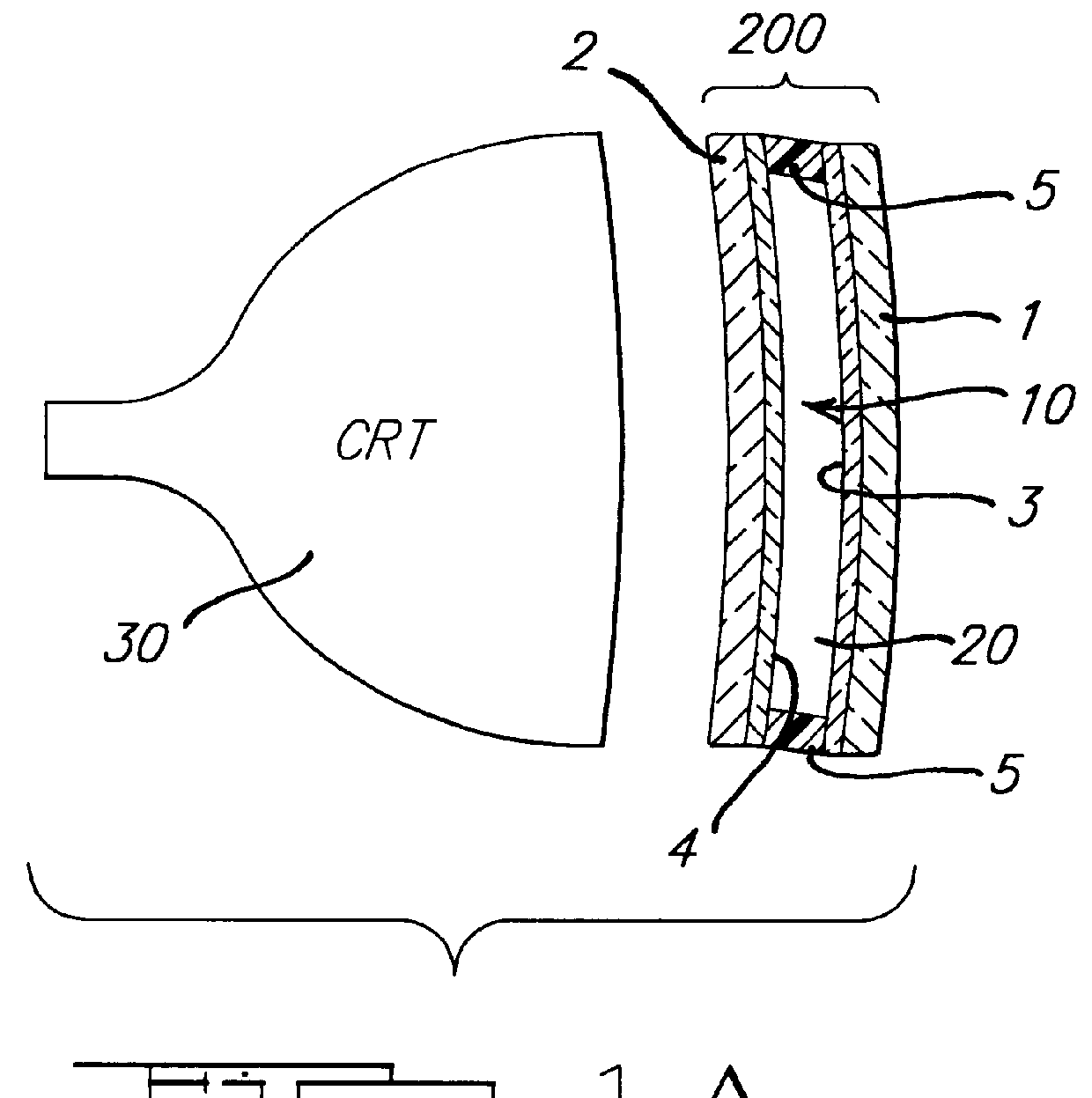

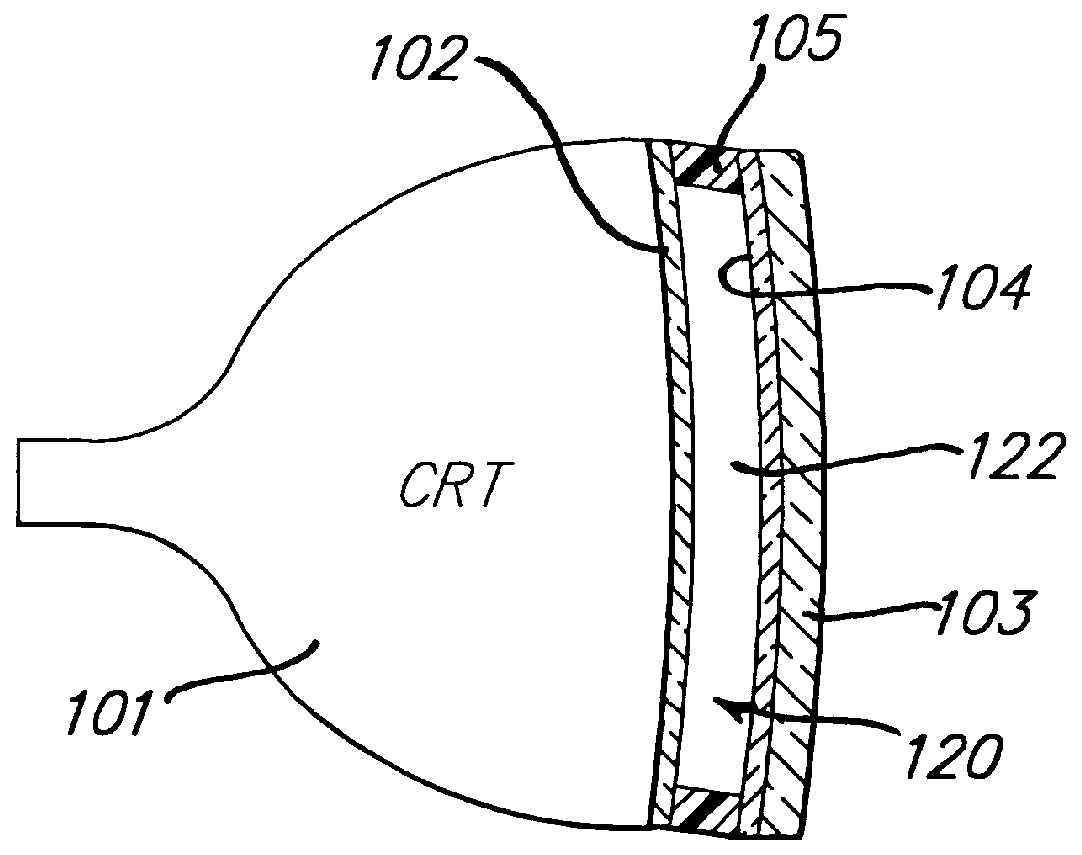

Image

Examples

example 3

An electrochromic medium containing a electrochromic compound composition consisting of 22 mM 5,10-dimethyl-5,10-dihydrophenazine, 6 mM 2-methyl-3-phenyl-5,10-dimethyl-5,10-dihydrophenazine (21 mol percent), and 34 mM 1,1'-bis(phenylpropyl)-4,4'-dipyridinium bis(tetrafluoroborate) in propylene carbonate is deoxygenated with dry nitrogen.

Application of 1.2V across the electrochromic device containing the electrochromic medium of Example 3 results in uniform coloration. The device changes from colorless to blue-gray. There is no staging noticed during darkening or clearing.

example 4

An electrochromic medium containing a electrochromic compound composition consisting of 21.5 mM 5,10-dimethyl-5,10-dihydrophenazine, 6.5 mM 2,5,7,10-tetramethyl-5,10-dihydrophenazine (23 mol percent), and 34 mM 1,1'-bis(phenylpropyl)-4,4'-dipyridinium bis(tetrafluoroborate) in propylene carbonate is deoxygenated with dry nitrogen.

Application of 1.2V across the electrochromic device containing the electrochromic medium of Example 4 results in uniform coloration. The device changes from colorless to blue-gray. There is no staging noticed during darkening or clearing.

example 5

An electrochromic medium containing a electrochromic compound composition consisting of 20 mM 5,10-dimethyl-5,10-dihydrophenazine, 8 mM 2-tertbutyl-5,7,10-trimethyl-5,10-dihydrophenazine (28.6 mol percent), and 34 mM 1,1'-bis(phenylpropyl)-4,4'-dipyridinium bis(tetrafluoroborate) in propylene carbonate is deoxygenated with dry nitrogen.

Application of 1.2V across the electrochromic device containing the electrochromic medium of Example 5 results in uniform coloration. The device changes from colorless to blue-gray. There is no staging noticed during darkening or clearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com