Method for controlling the engagement force of the synchronizers of a dual clutch transmission

a technology of synchronizer and engagement force, which is applied in the direction of mechanically actuated clutches, gearing details, gearing, etc., can solve the problems of loss of efficiency, interruption of drive connection, and large physical interaction required by the operator, and achieve smooth and efficient movement of the synchronizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

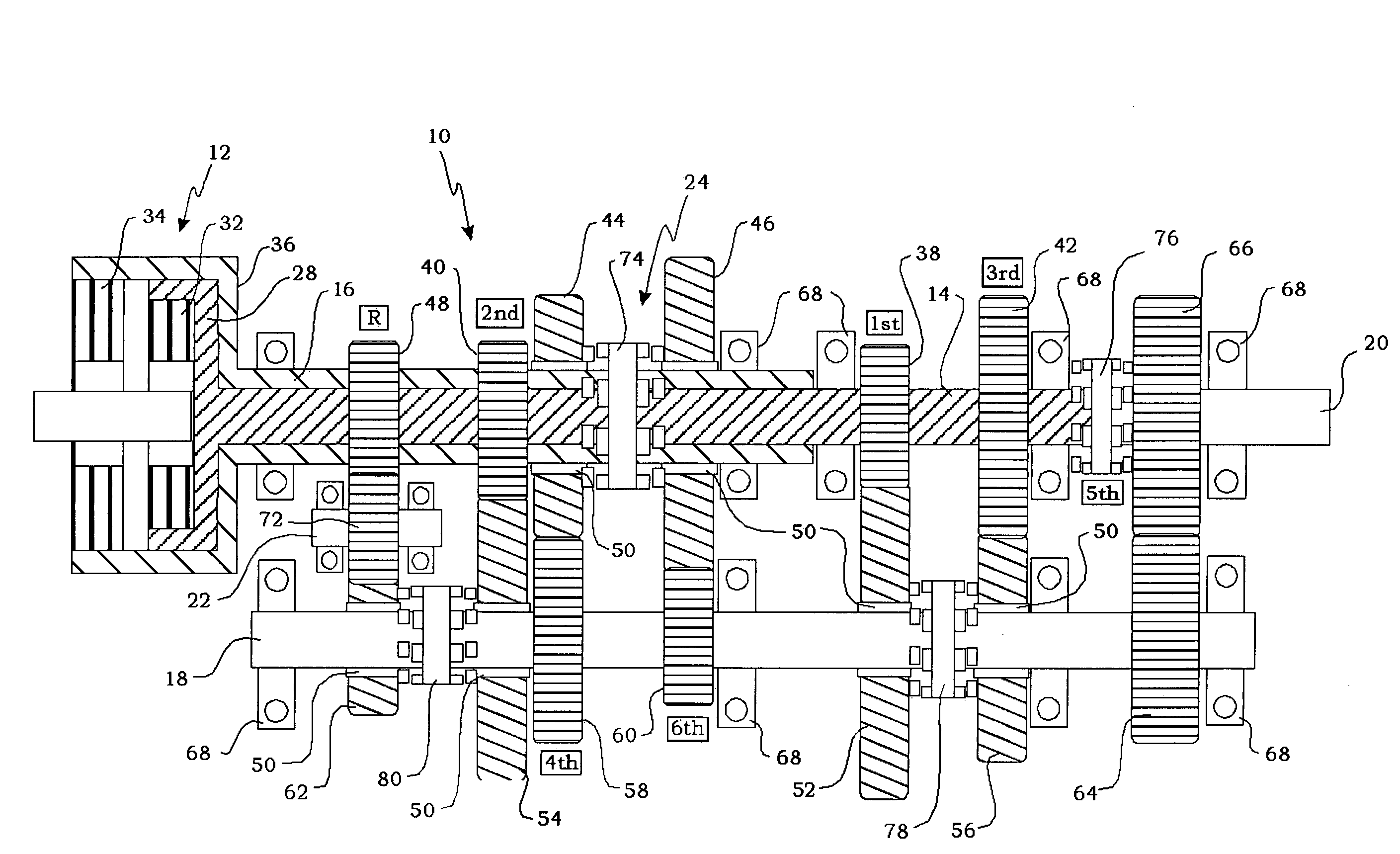

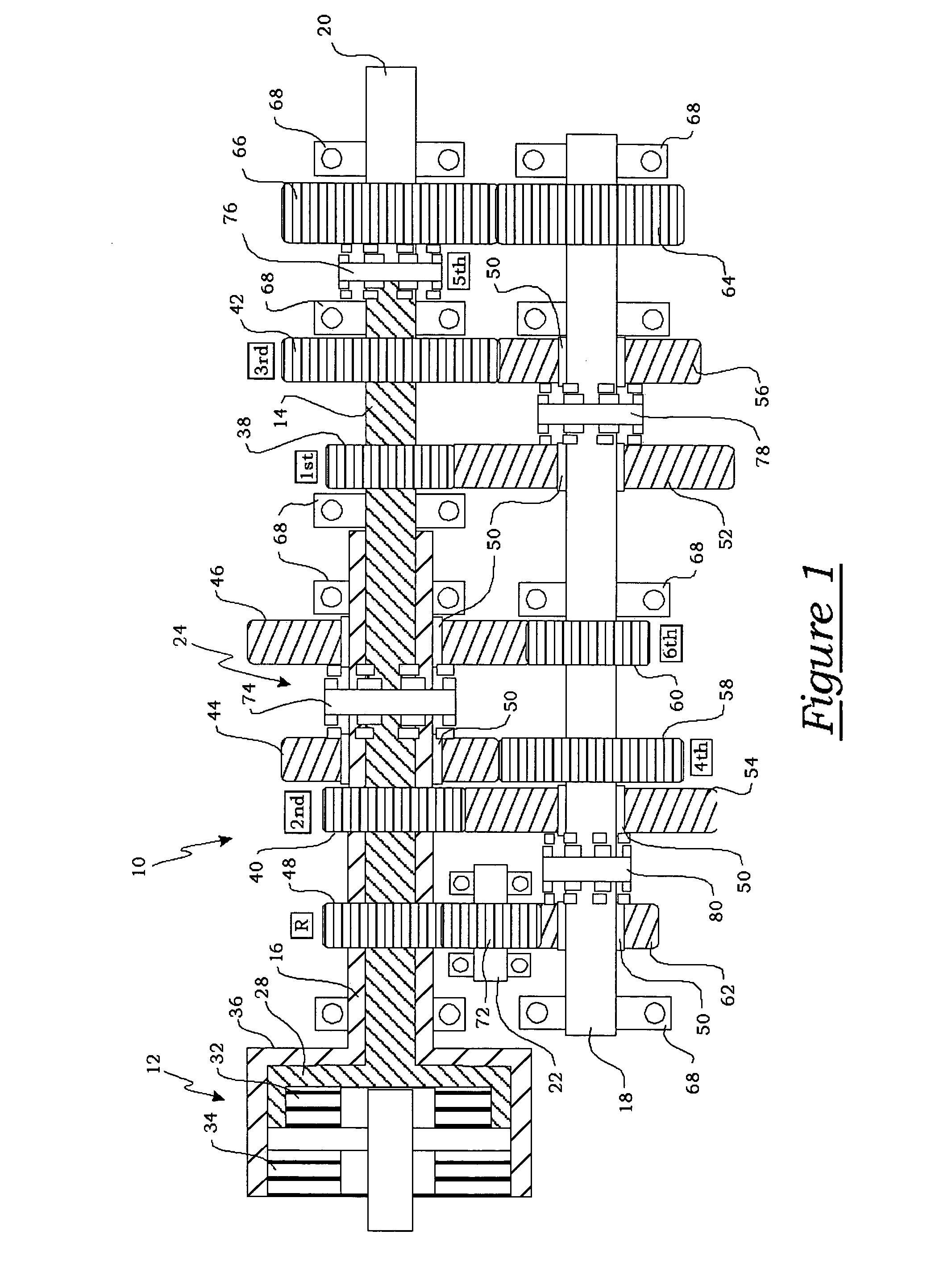

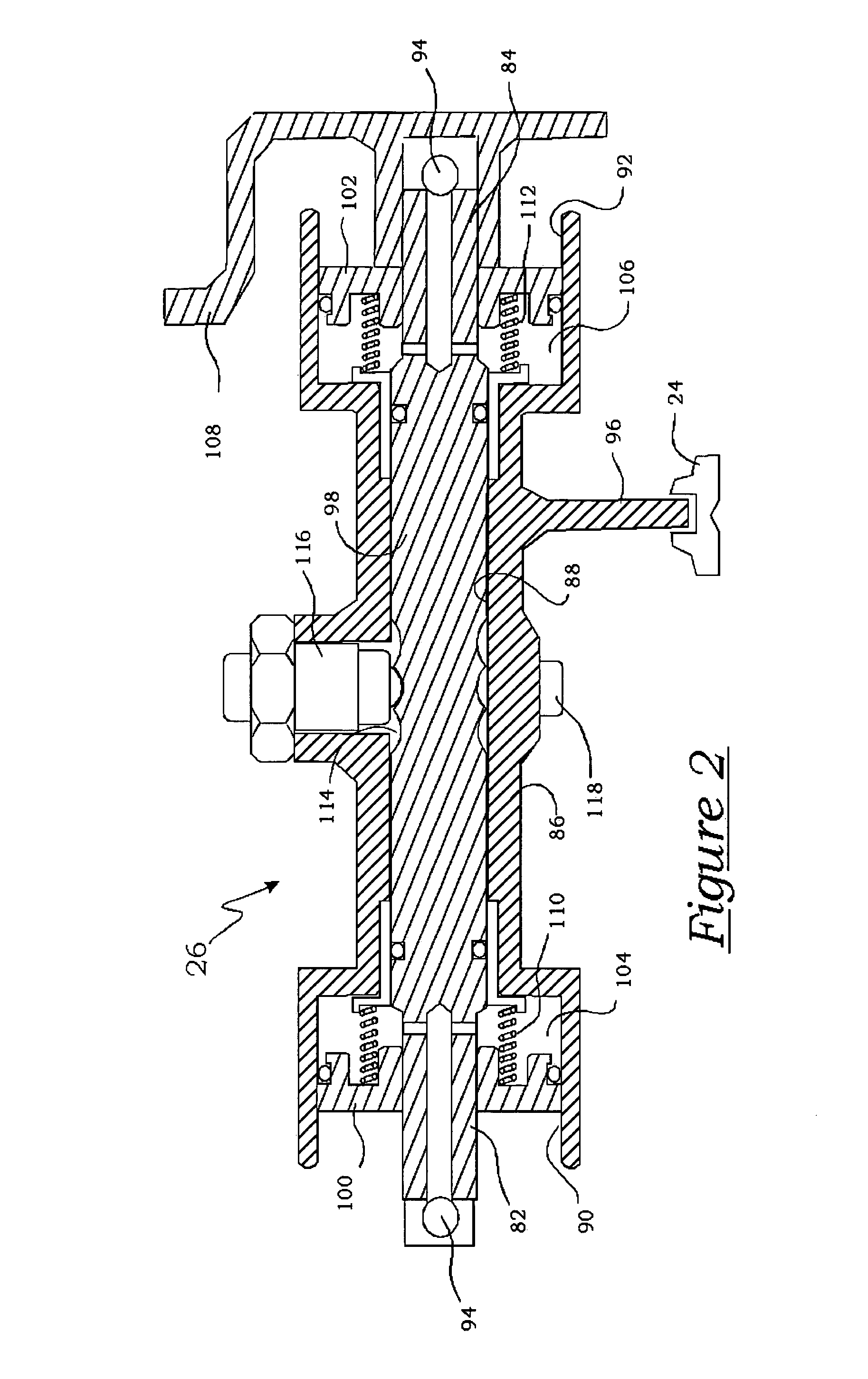

[0022]A representative dual clutch transmission that may be controlled by the present invention is generally indicated at 10 in the schematic illustrated in FIG. 1. Specifically, as shown in FIG. 1, the dual clutch transmission 10 includes a dual, coaxial clutch assembly generally indicated at 12, a first input shaft, generally indicated at 14, a second input shaft, generally indicated at 16, that is coaxial to the first, a counter shaft, generally indicated at 18, an output shaft 20, a reverse counter shaft 22, a plurality of synchronizers, generally indicated at 24, and a plurality of shift actuators generally indicated at 26 (FIG. 2).

[0023]The dual clutch transmission 10 forms a portion of a vehicle powertrain and is responsible for taking a torque input from a prime mover, such as an internal combustion engine, and transmitting the torque through selectable gear ratios to the vehicle drive wheels. The dual clutch transmission 10 operatively routes the applied torque from the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com