Motor drive control apparatus

a control apparatus and motor technology, applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, instruments, etc., can solve the problems of increasing the size of linear vibration motors, unnecessary restrictions such as securing the operation reliability of sensors, etc., to save the global environment, reduce the loss of friction loss in compressors, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

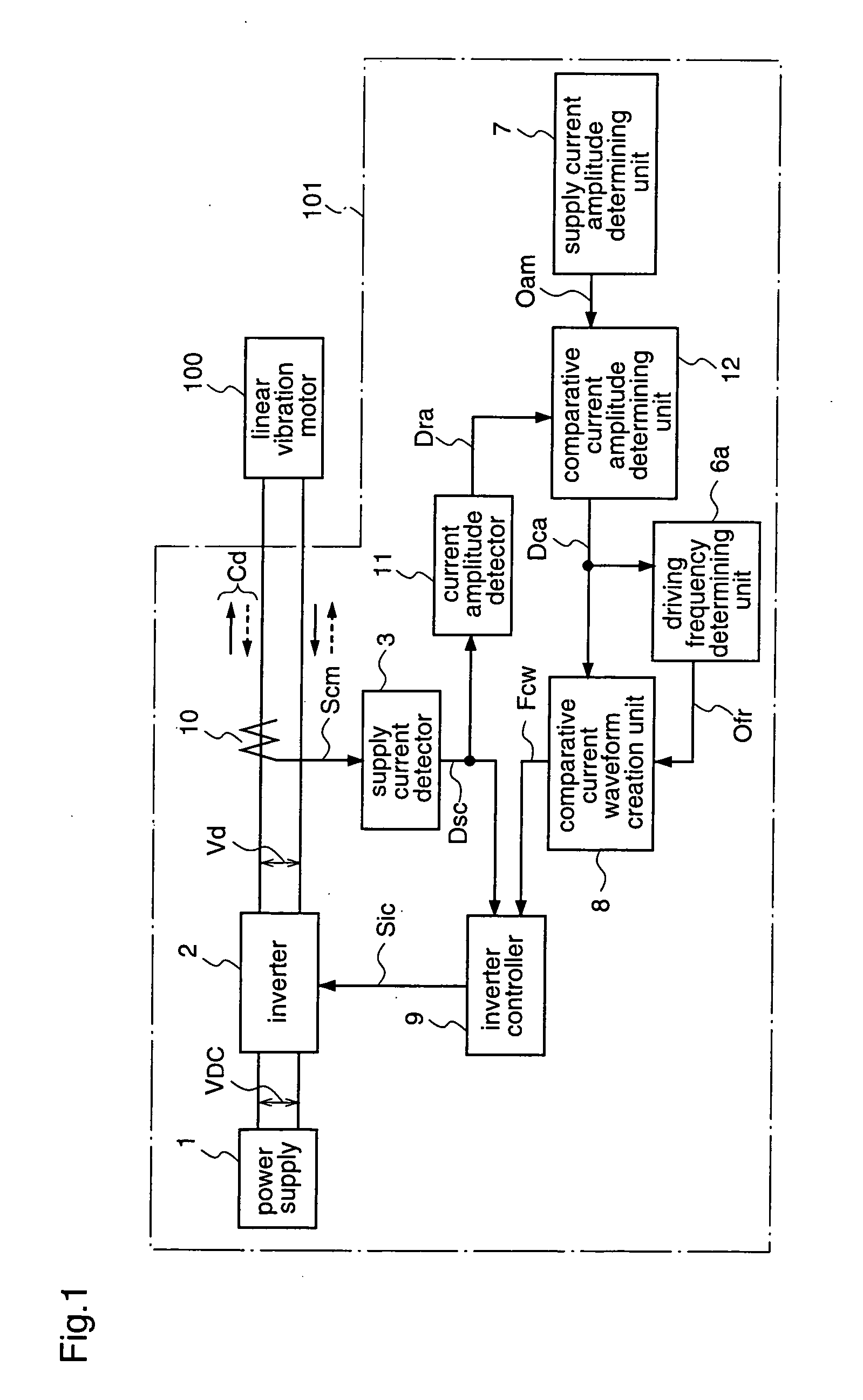

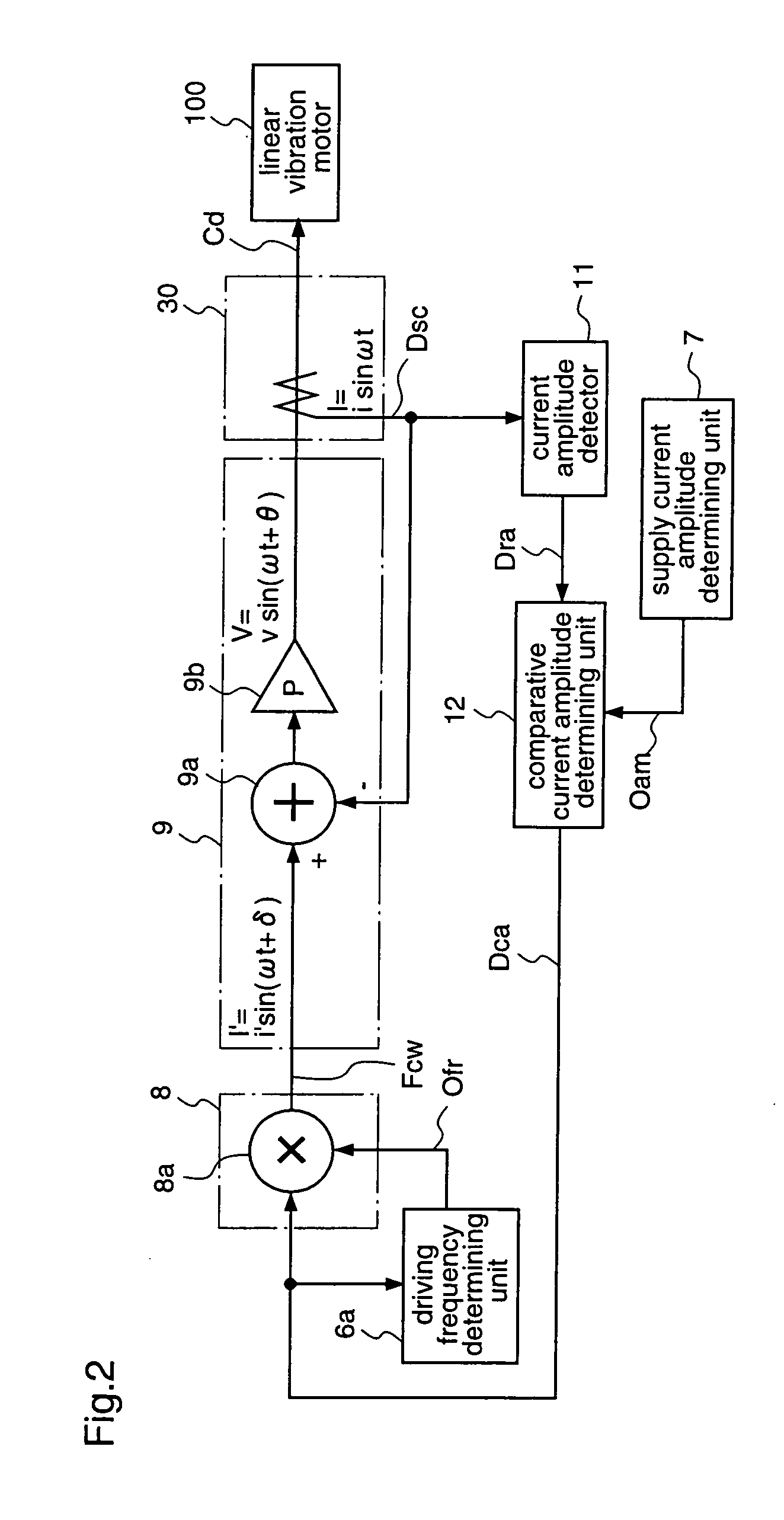

[0055]FIG. 1 is a block diagram for explaining a motor drive control apparatus according to the first embodiment of the present invention.

[0056]A motor drive control apparatus 101 according to the first embodiment performs feedback drive control for a linear vibration motor 100 which has a stator and a mover, and supports the mover with a spring so as to form a spring vibration system including the mover, on the basis of a comparative current waveform (first AC current waveform) as a reference of a driving current of the linear vibration motor 100. One of the stator and the mover comprises an electromagnet while the other comprises an electromagnet or a permanent magnet.

[0057]More specifically, the motor drive control apparatus 101 includes: a power source 1 for generating a DC voltage VDC as a power supply voltage; an inverter 2 for converting the power supply voltage VDC into an AC voltage Vd of a predetermined frequency, and supplying the converted AC voltage Vd to the linear vib...

second embodiment

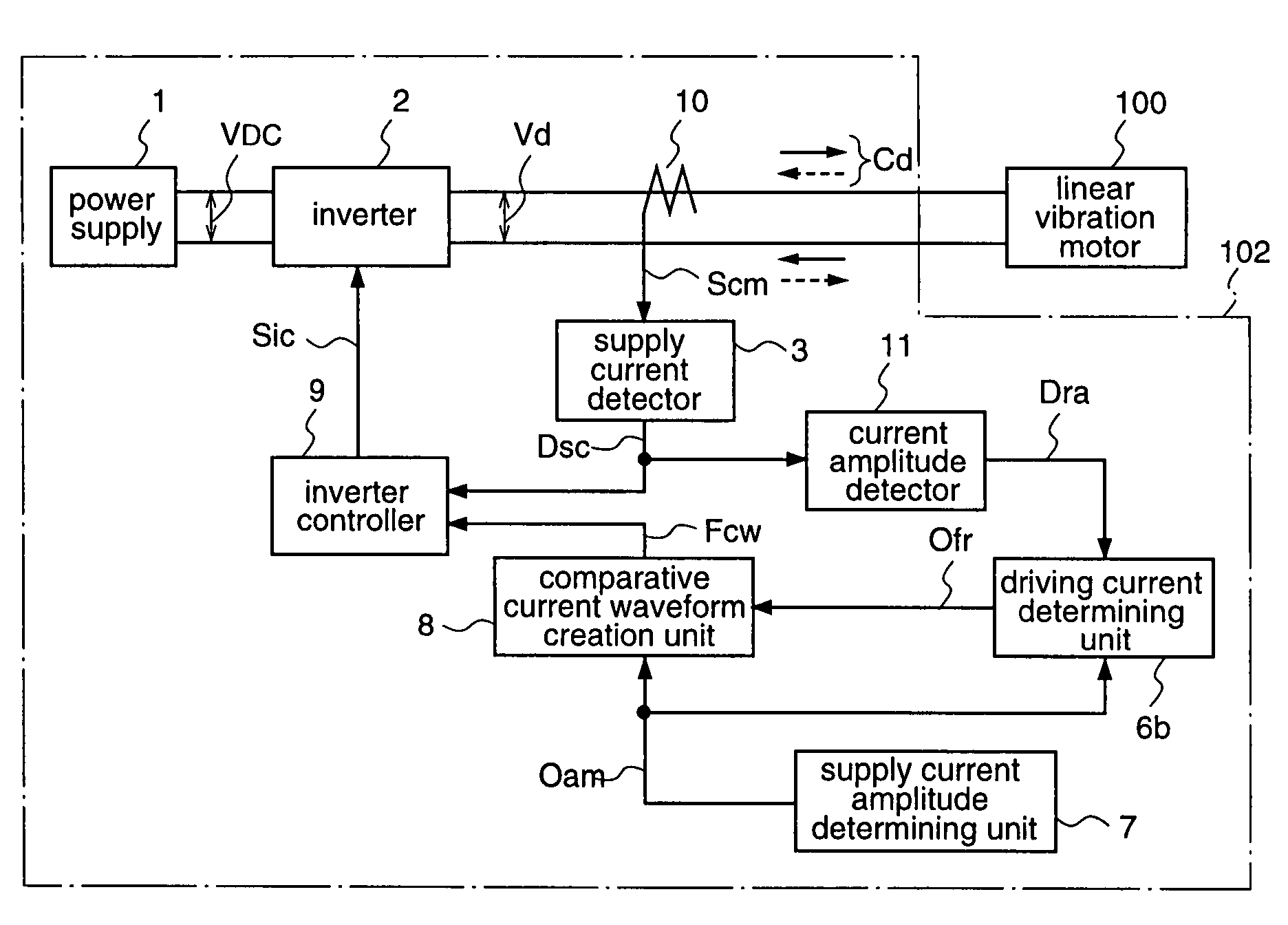

[0132]FIG. 4 is a block diagram illustrating a motor drive control apparatus according to a second embodiment of the present invention.

[0133]A linear vibration motor drive control apparatus 102 according to the second embodiment is provided with, instead of the comparative current amplitude value determining unit 12 and the driving frequency determining unit 6a of the first embodiment, a driving frequency determining unit 6b for determining a driving frequency ω of the inverter supply voltage Vd on the basis of the target amplitude value i″ of the inverter supply current Cd that is determined by the supply current amplitude determining unit 7 and the actual amplitude value i of the inverter supply current Cd that is detected by the current amplitude detector 11.

[0134]A power supply 1, an inverter 2, a supply current detector 3, a supply current amplitude determining unit 7, a comparative current waveform creation unit 8, an inverter controller 9, a current sensor 10, and a current a...

third embodiment

[0166]FIG. 7 is a block diagram for explaining a motor drive control apparatus according to a third embodiment of the present invention.

[0167]A motor drive control apparatus 103 according to the third embodiment performs feedback drive control of a linear vibration motor 100 having a stator and a mover, which is supported with a spring so as to form a spring vibration system including the mover, on the basis of a driving voltage and a driving current of the linear vibration motor 100, similar to the motor drive control apparatus 101 according to the first embodiment. This third embodiment is different from the first embodiment in that the frequency of an AC current as the driving current is determined on the basis of a power applied to the linear vibration motor 100, whereas the frequency of an AC current as the driving current is determined on the basis of the driving current of the linear vibration motor in the first embodiment. One of the stator and the mover comprises an electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com