Antenna for RFID

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental examples

[0040]Next, Experimental Examples of the present invention are described below in detail together with Comparative Examples.

experimental example 1

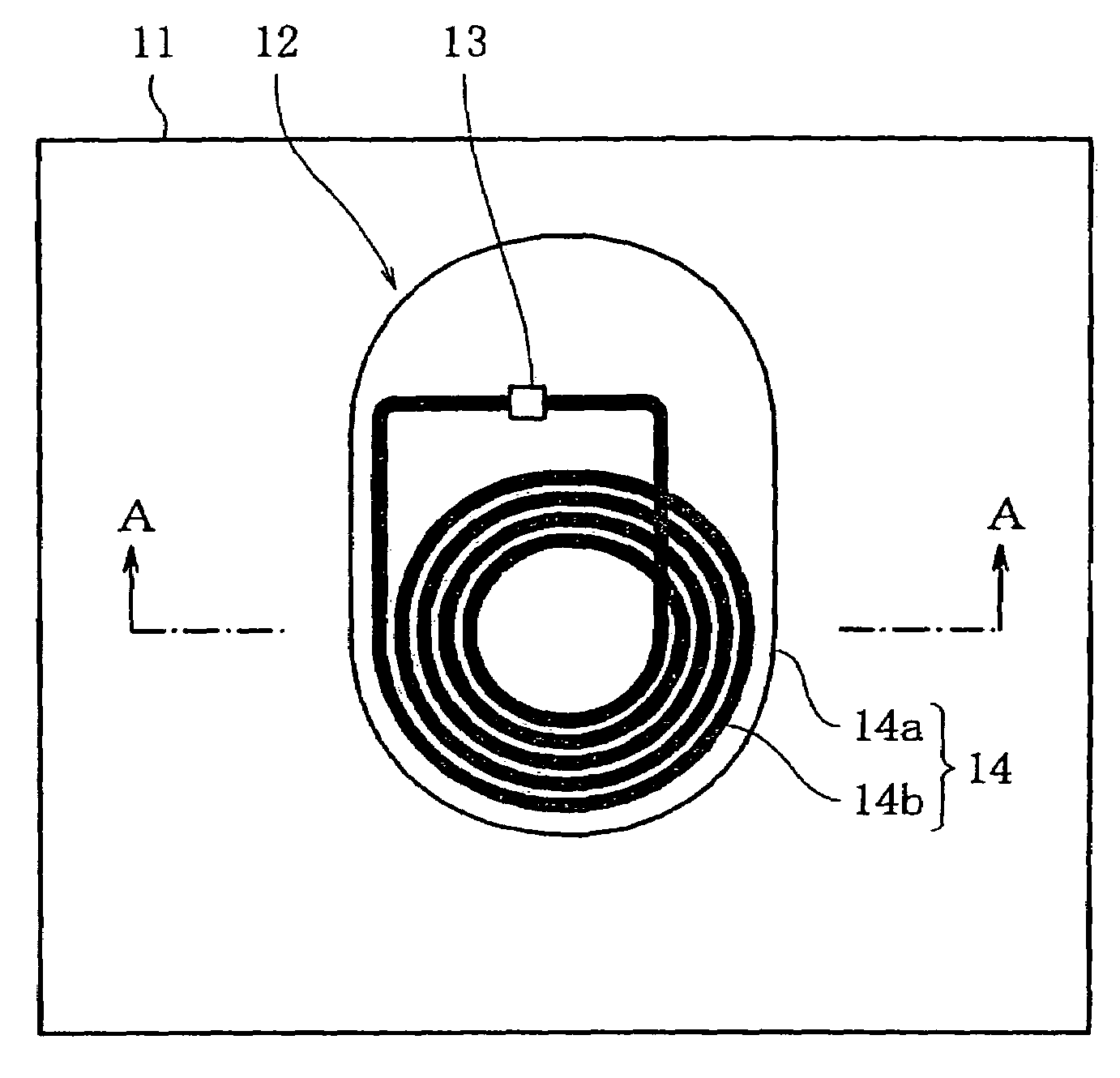

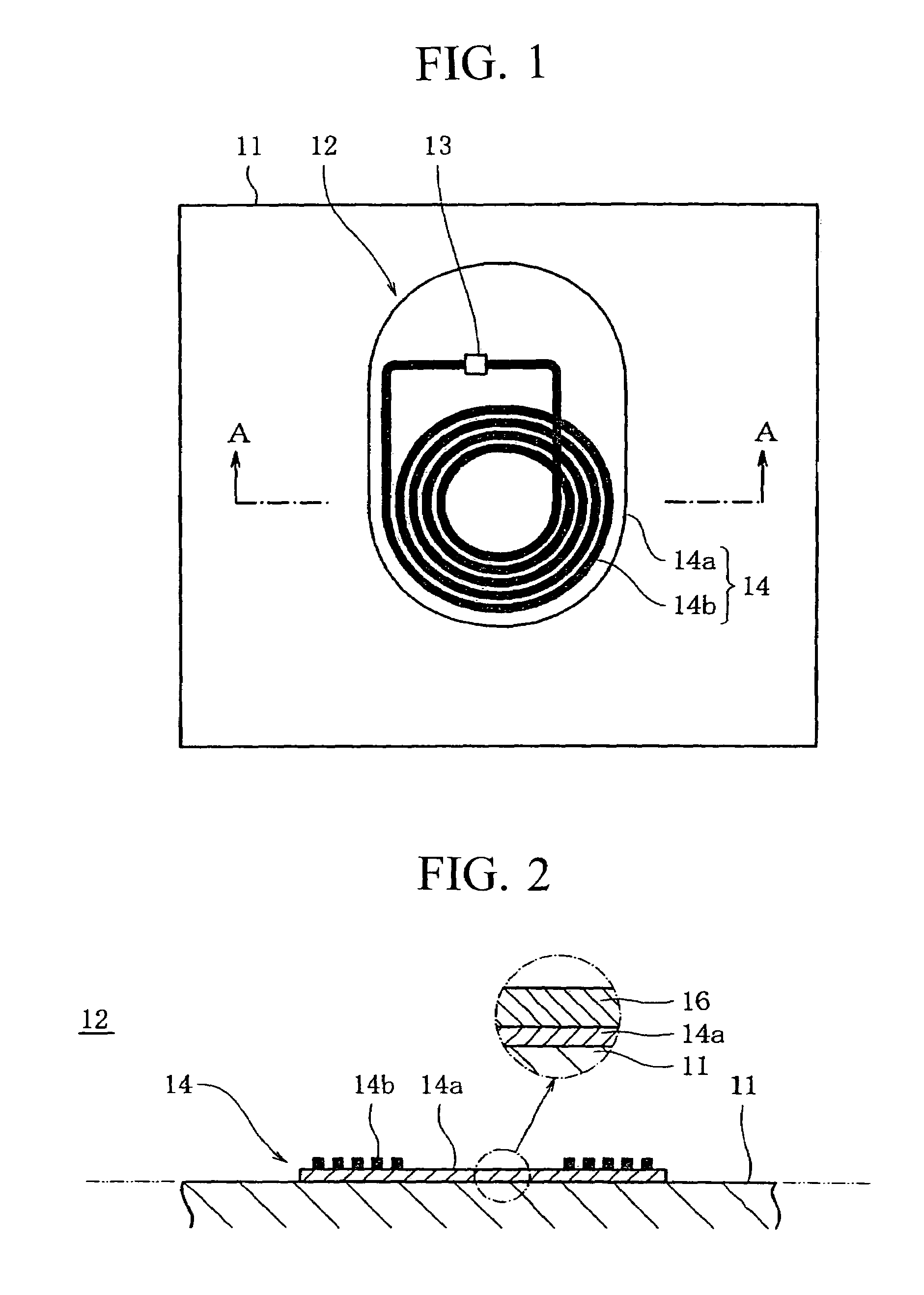

[0041]As shown in FIGS. 1 and 2, a coil body with an outer diameter of 50 mm and an inner diameter of 49 mm was made by winding a coated copper wire having a diameter of 0.2 mm four to five times. Moreover, a mild-steel plate having a size of 100×100 mm and a thickness of 0.16 mm was prepared as an article and a non-metallic acrylic plate having the same shape and size as the mild-steel plate was also prepared for comparison. As a conductive member, an aluminum plate having a size of 50×50 mm and a thickness of 0.2 mm was affixed to the surfaces of the mild-steel plate and acrylic plate, respectively. Then, the L1 value and the Q1 value of the coil body were measured by directly affixing the coil body at the surface of the aluminum plate which is affixed on the mild-steel plate, or by maintaining a predetermined interval to the surface of the aluminum plate. Thereafter, the values of L2 and Q2 were measured by directly affixing the coil body at the surface of the aluminum plate whic...

experimental example 2

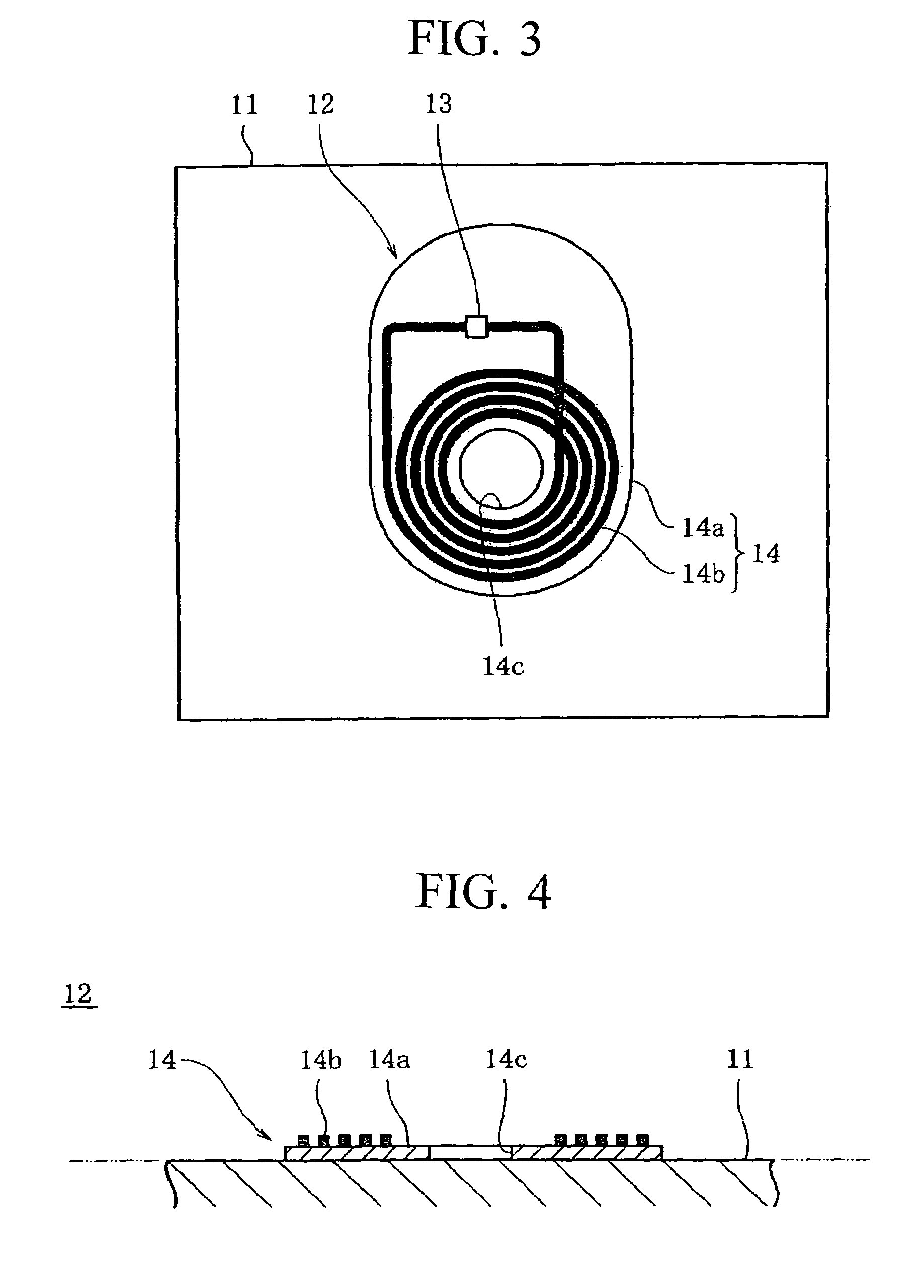

[0042]A soft magnetic member was set between the coil body and aluminum plate of the Experimental Example 1. The soft magnetic member used a member having an outer diameter of 60 mm and a thickness of 0.34 mm which was obtained by injection-molding a composite material made of 72% of carbonyl iron and polyethylene and then compressing the moulded composite material. The coil body of the Experimental Example 1 was brought into close contact with the surface of the soft magnetic member 26 to measure the L1 value and the Q1 value of the coil body by directly bringing the back of the soft magnetic member 26 into contact with the surface of an aluminum plate set on the mild-steel plate of the Experimental Example 1 or setting the soft magnetic member 26 by maintaining a predetermined interval. Then, the L2 value and the Q2 value of the coil body were measured by directly bringing the back of the soft magnetic member 26 into contact with the surface of the aluminum plate set on the acryli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com