Method and apparatus for determining recording pulse parameters for an optical disc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

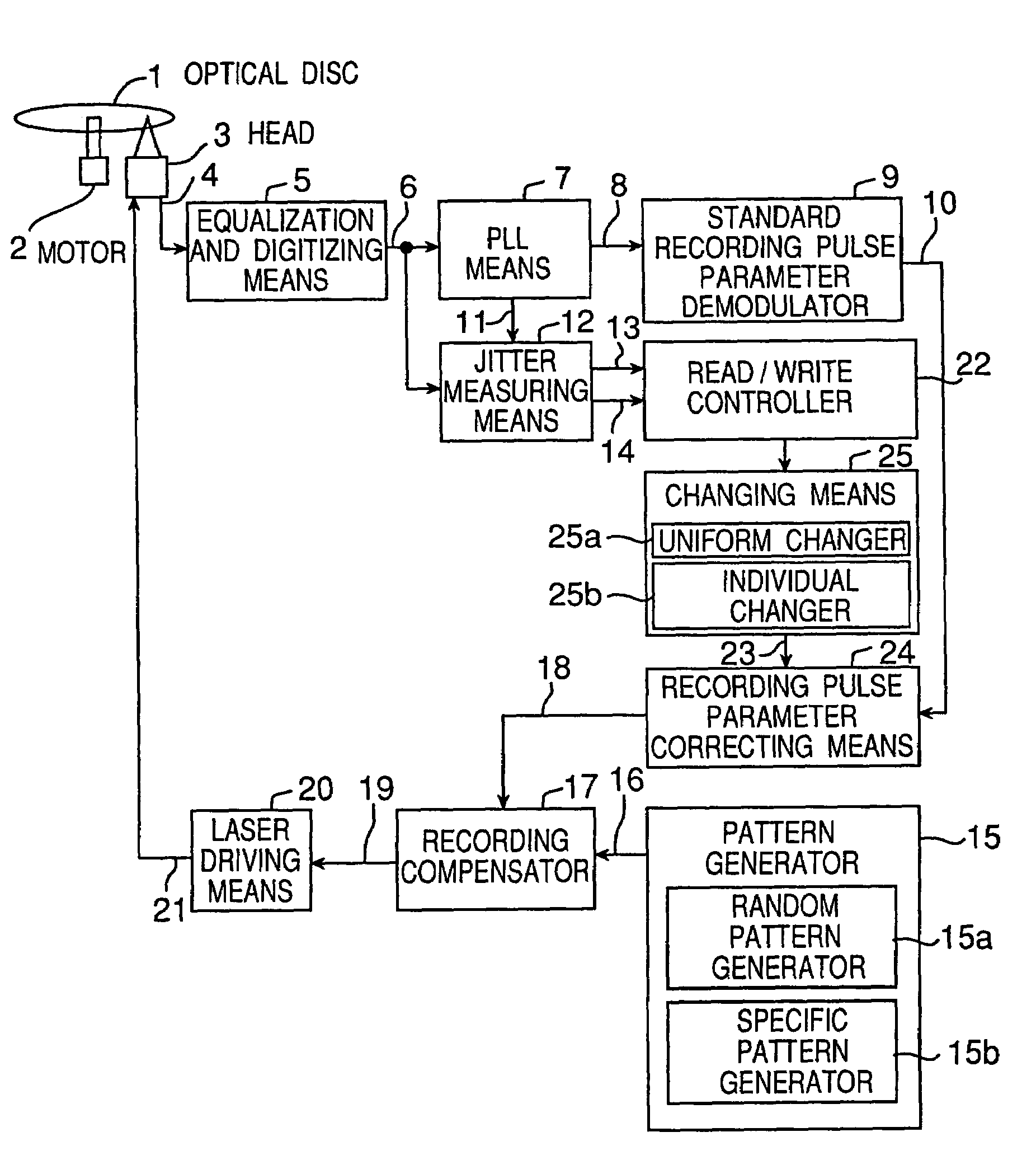

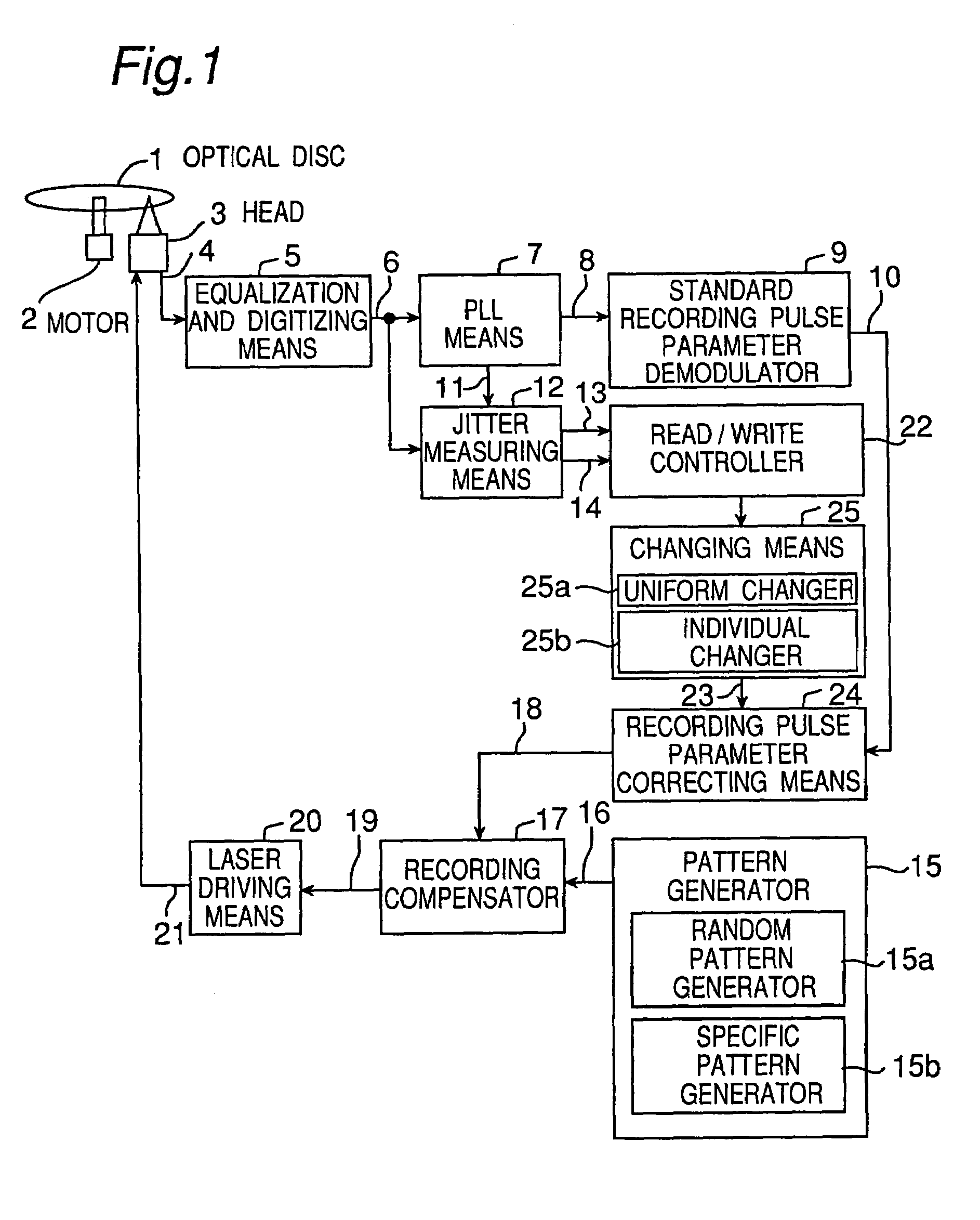

[0075]FIG. 1 is a block diagram of an optical disc recording and reproducing device that implements the optical disc recording parameter determining method of the present invention. The components and signals of this device are described first. Reference numeral 1 is a writable phase-change type optical disc; reference numeral 2 is a motor for rotating the optical disc 1; reference numeral 3 is a head for reading recorded data from the rotating optical disc 1 and obtaining read signal 4; reference numeral 5 is an equalization and digitizing means for obtaining a digital binary signal 6 from the analog read signal by means of a duty feedback slice method after compensating the frequency characteristic of read signal 4; reference numeral 7 is a PLL for detecting the edge of binary signal 6, generating a read clock synchronized thereto, and converting the binary signal 6 to data 8 synchronized to the read clock, and outputting as phase difference pulse 11 the time-based offset between ...

embodiment 2

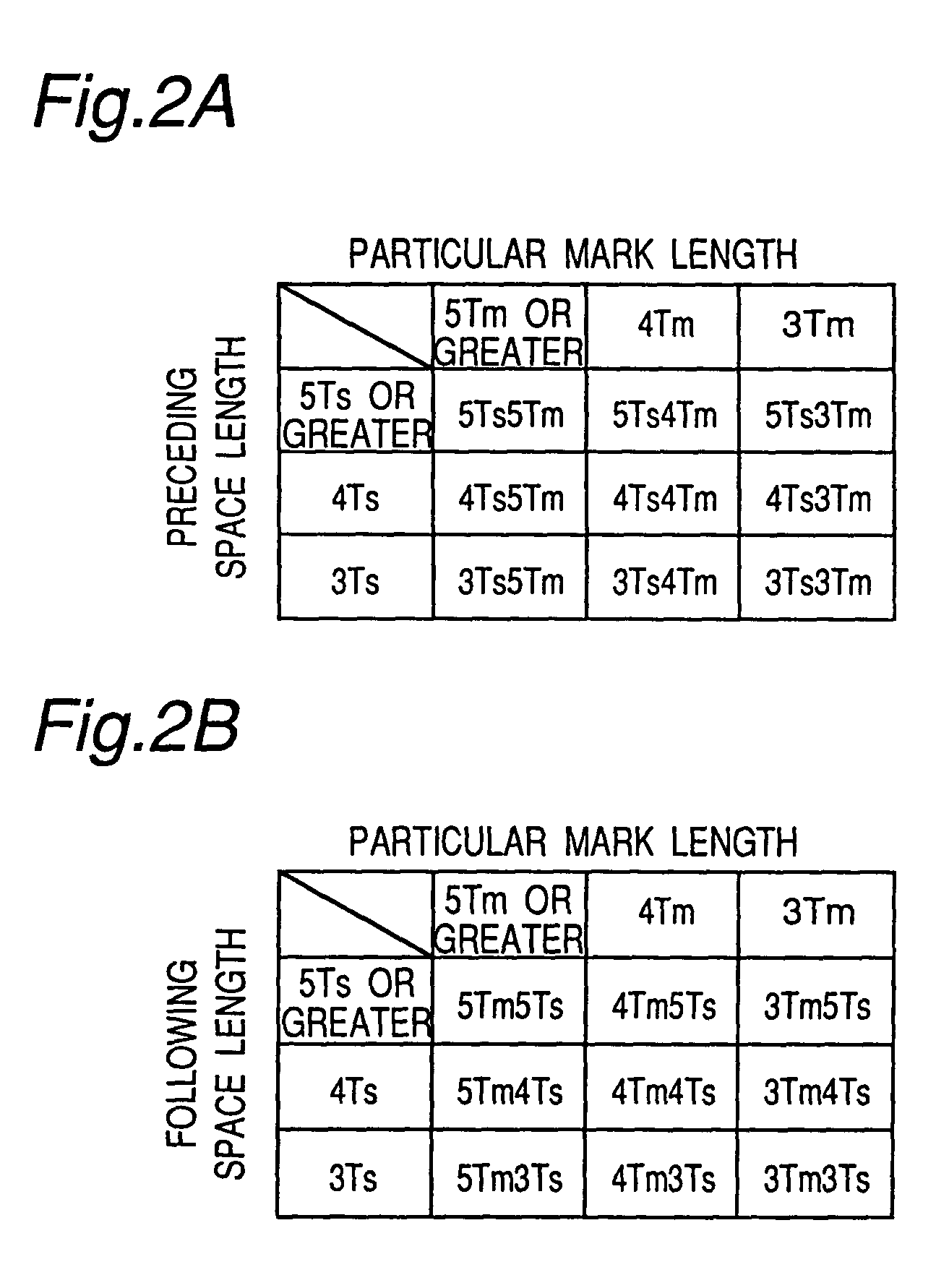

[0097]Described next below is a specific optical disc recording parameter determining method whereby good recording characteristics can be achieved with a writable optical disc wherein standard recording pulse parameters are recorded to a specific disc area even when there is a difference between the optical disc characteristics and standard recording pulse parameters. This second embodiment of the invention is also described with reference to FIG. 1. Those parts that differ from the above first embodiment are described below while further description of the same parts is omitted. In this embodiment two of the eighteen recording pulse parameters, that is, 5Ts5Tm and 5Tm5Ts, use the standard recording pulse parameters as is. Twelve different corresponding recording patterns are used to determine the remaining sixteen recording pulse parameters. These twelve recording patterns are generated by the specific pattern generator 15b of the pattern generating means 15.

[0098]The relationship...

embodiment 3

[0116]Next is described a specific method for reducing the number of read / write operations and shortening time required when compared with the steps of the second embodiment.

[0117]When the leading mark-edge pulse parameter is 5Ts3Tm in FIG. 2, the correction value is determined as described in the above-noted second embodiment using recording pattern (3) in FIG. 7. When the leading mark-edge pulse parameter is 3Ts3Tm in FIG. 2, the correction value is determined using recording pattern (11) in FIG. 7. Then, when the leading mark-edge pulse parameter is 4Ts3Tm, the correction value is not determined using recording pattern (7), but rather is calculated by, for example, interpolating the 4Ts3Tm correction value from the relationship between the 5Ts3Tm correction value as determined above, the 5Ts3Tm value of the standard parameters, the 3Ts3Tm correction value as determined above, the 3Ts3Tm value of the standard parameters, and the 4Ts3Tm value of the standard parameters. Because the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com