Method of prepregging with resin and novel prepregs produced by such method

a technology of resin and prepregs, which is applied in the field of apparatus and methods of prepregs, can solve the problems of increased process steps, unsatisfactory results, and increased labor costs, and achieves the effects of easy manufacturing into articles, low viscosity, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

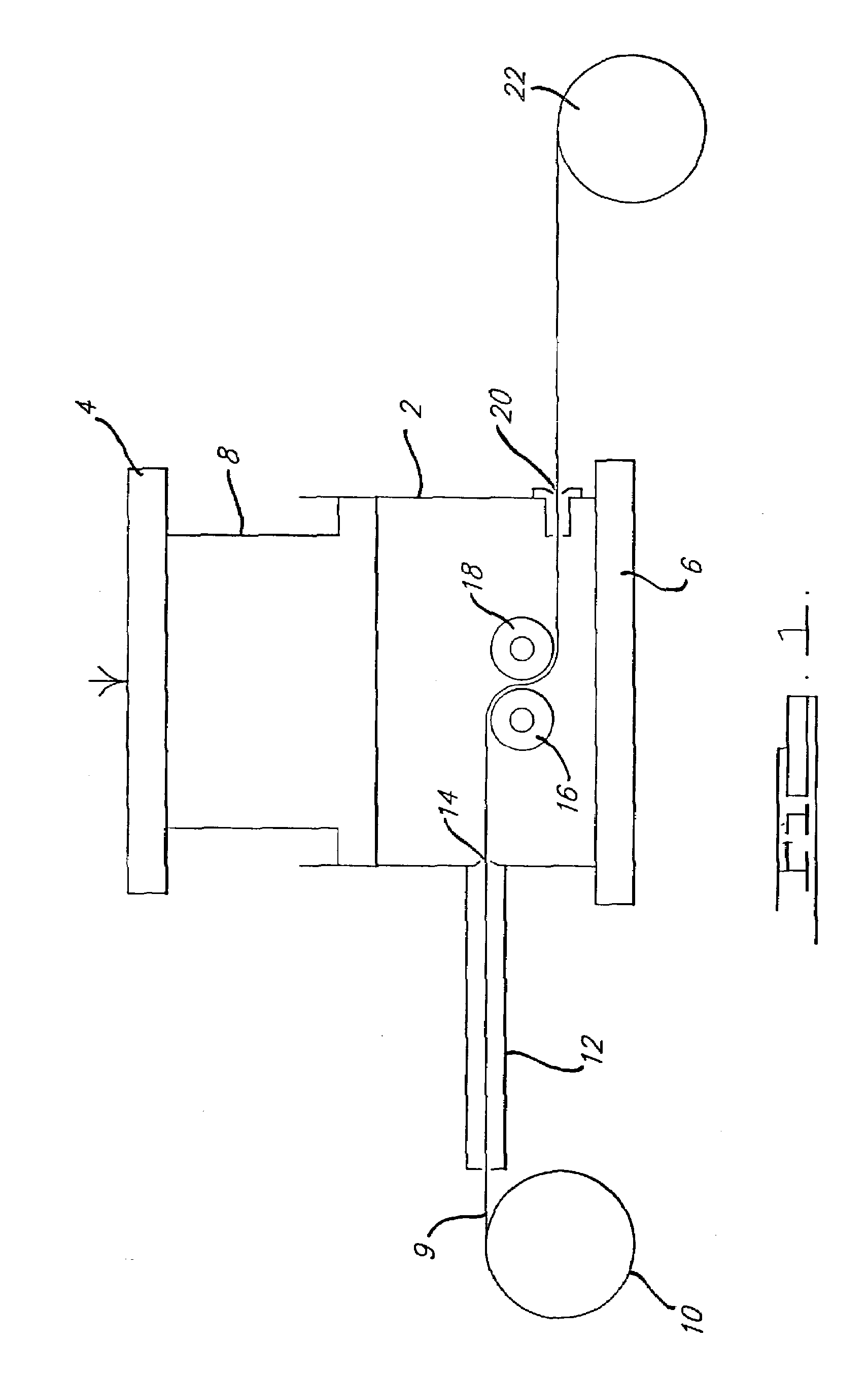

[0039]Referring now to FIG. 1, 1 kg of amorphous nylon resin (Grivory 21, available from EMS-American Grilion Inc., Sumpter, S.C.) is charged to resin tank 2 between heated platens 4 and 6. The resin is heated to about 465° F. under a pressure of about 28 psi applied from piston 8. A roving of S2 glass (750 yield, 933 sizing, available from Owens Corning, Corning N.Y.) is pulled from a creel 10 and through an 18 inch radiant heat tube 12, the tube being heated to a temperature of about 595° F. Exiting the heat tube, the roving is passed through a tapered fiber inlet die 14, over and around two 0.3 inch radius shear pins 16 and 18 heated to 495° F. and positioned about one inch apart horizontally and about 1.5 inches apart horizontally in the resin bath, and finally through a sizing die 20 located opposite the inlet die. The sizing die has a rectangular cross section with a dimensions of 0.25 in.×0.009 in. The hot fiber is pulled at a rate of about 42 ft / min. through the bath. The re...

example 2

[0040]A tow of S2 glass (750 yield, 933 sizing, available from Owens Corning, Corning N.Y.) is impregnated with amorphous nylon resin (Grivory 21, available from EMS-American Grilion Inc., Sumpter, S.C.) using the same procedure described in Example 1, except that the resulting impregnated tow is sized to 0.25 in. wide and 0.011 in. thick. The impregnated tow has a resin content of 54% by weight. The impregnated tow is chopped into three-inch section. The chopped impregnated tow, 713.25 grams, is placed into a 10 in.×18 in. tool that is preheated to 515° F. and is pressurized to 300 psi for 8 min. The tool is then quenched. The resulting part weighs 653 grams and has an average thickness of 3.82 mm.

example 3

[0041]A woven S2 fiberglass cloth with Owens Corning 933 sizing is impregnated with the same amorphous nylon resin and is used in Examples 1 and 2. The fiberglass cloth has the following parameters: FDI Style # 1406 (a designation of Fabric Development Corporation, Quakertown, Pa.); yarn type, S2 glass 75 1 / 0, 933A; weave, 8 harness satin; count, 120×30; width, 39.25 in.; weight, 11.74 oz per square yard; and thickness, 0.0017 in. as measured at 1 psi.

[0042]The nylon is extruded into a film 0.0045 in. thick and placed on a creel. The S2 cloth is also on a creel.

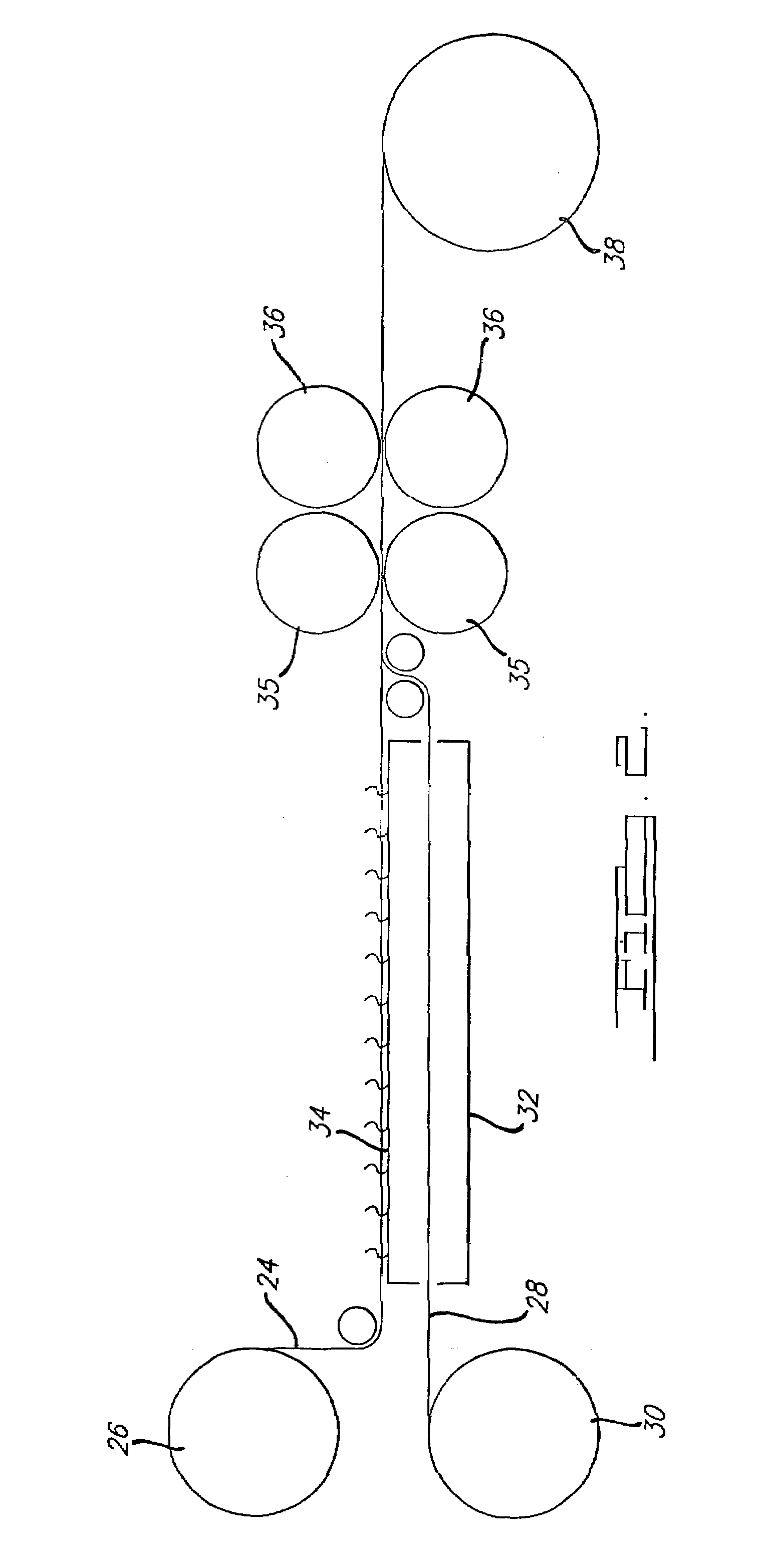

[0043]Referring now to FIG. 2, the nylon film 24 is pulled from creel 26 and the glass cloth 28 is pulled from creel 30. The glass cloth is pulled through a radiant heater 32. The radiant heater heats the fiber to 600° F., while a reinforced Teflon® sleeve 34 on top of the heater carries the film. Heat escaping from the heater raises the temperature of the film to between 425 and 475° F. The cloth and the film are then fed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com