Control sequencing and prognostics health monitoring for digital power conversion and load management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]Aspects of the invention are more specifically set forth in the accompanying description with reference to the appended Figures.

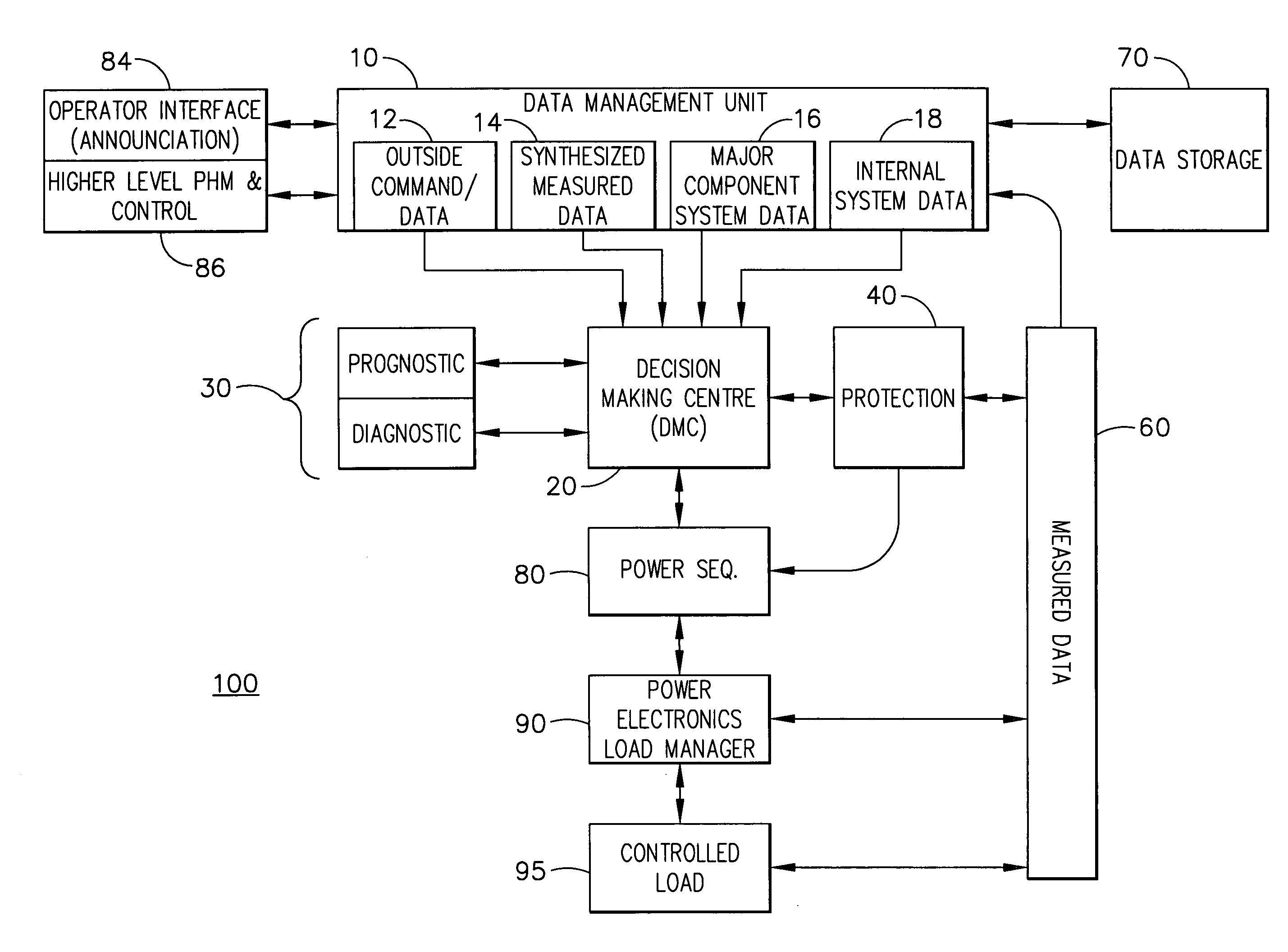

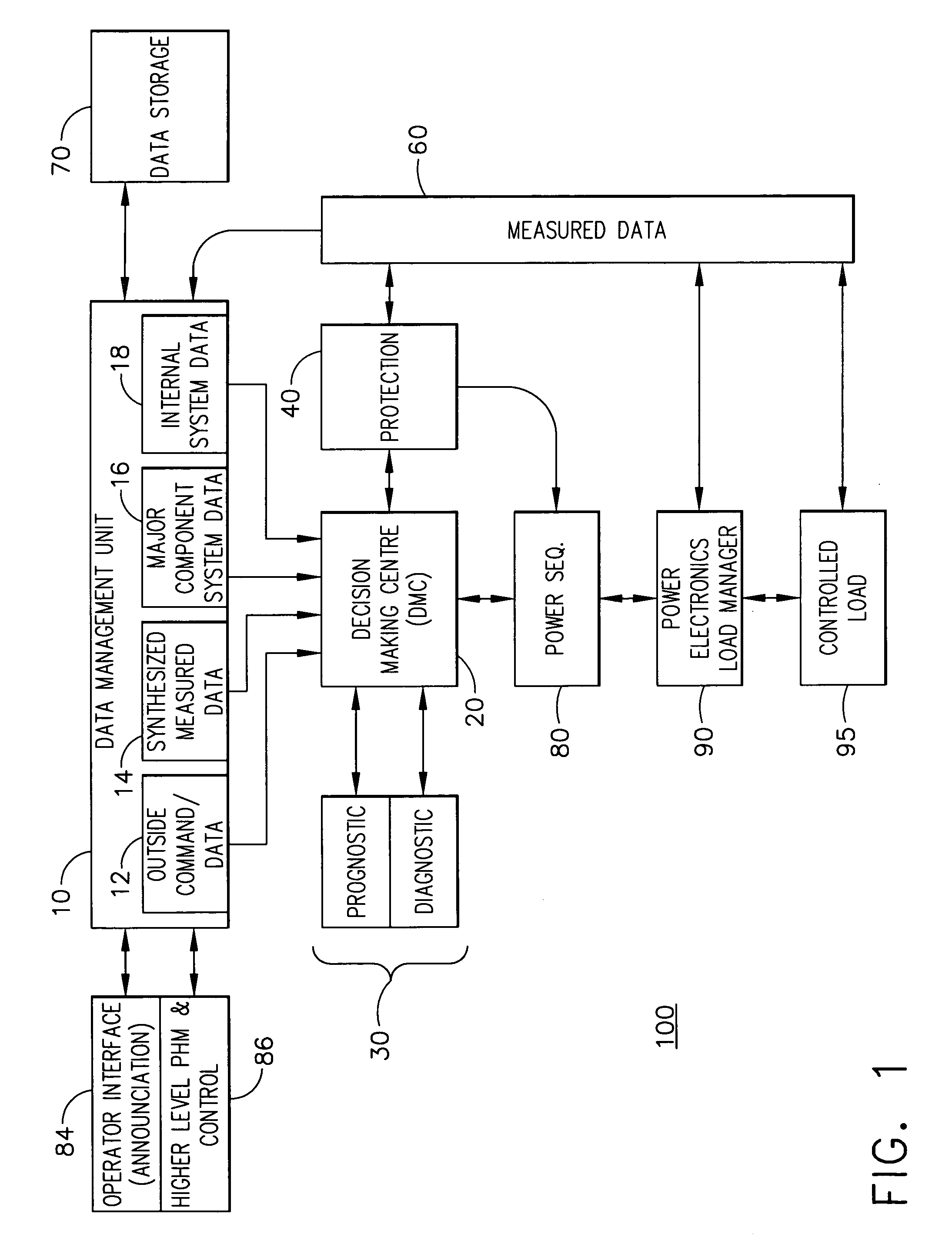

[0053]FIG. 1 illustrates a block diagram of a control sequencing and prognostic health monitoring system for digital power conversion and load management according to an embodiment of the present invention. The system 100 illustrated in FIG. 1 includes the following components: a data management unit (DMU) 10; a decision making center (DMC) 20; a prognostics health monitoring and diagnostics (PHMD) unit 30; a protection unit 40; a data measuring unit 60; a data storage unit 70; a power sequencing control unit 80; an operator interface 84; a higher level PHM and control unit 86; a power electronics load manager (PELM) 90; and a controlled load 95. The controlled load 95 may be any of numerous types of loads, including an active motor load such as an induction motor, synchronous machine or a Brushless DC motor or other passive load. The PELM 90 may be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com