Parabolic trough solar collector for fluid heating and photovoltaic cells

a solar collector and fluid heating technology, applied in the safety of solar heat collectors, lighting and heating apparatus, furnaces, etc., can solve the problems of high cost of maintenance, low efficiency of solar power generating plants, and low cost of maintenance, so as to reduce weight and cost, the support of fixed conduits and suspended reflector panels is simplified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

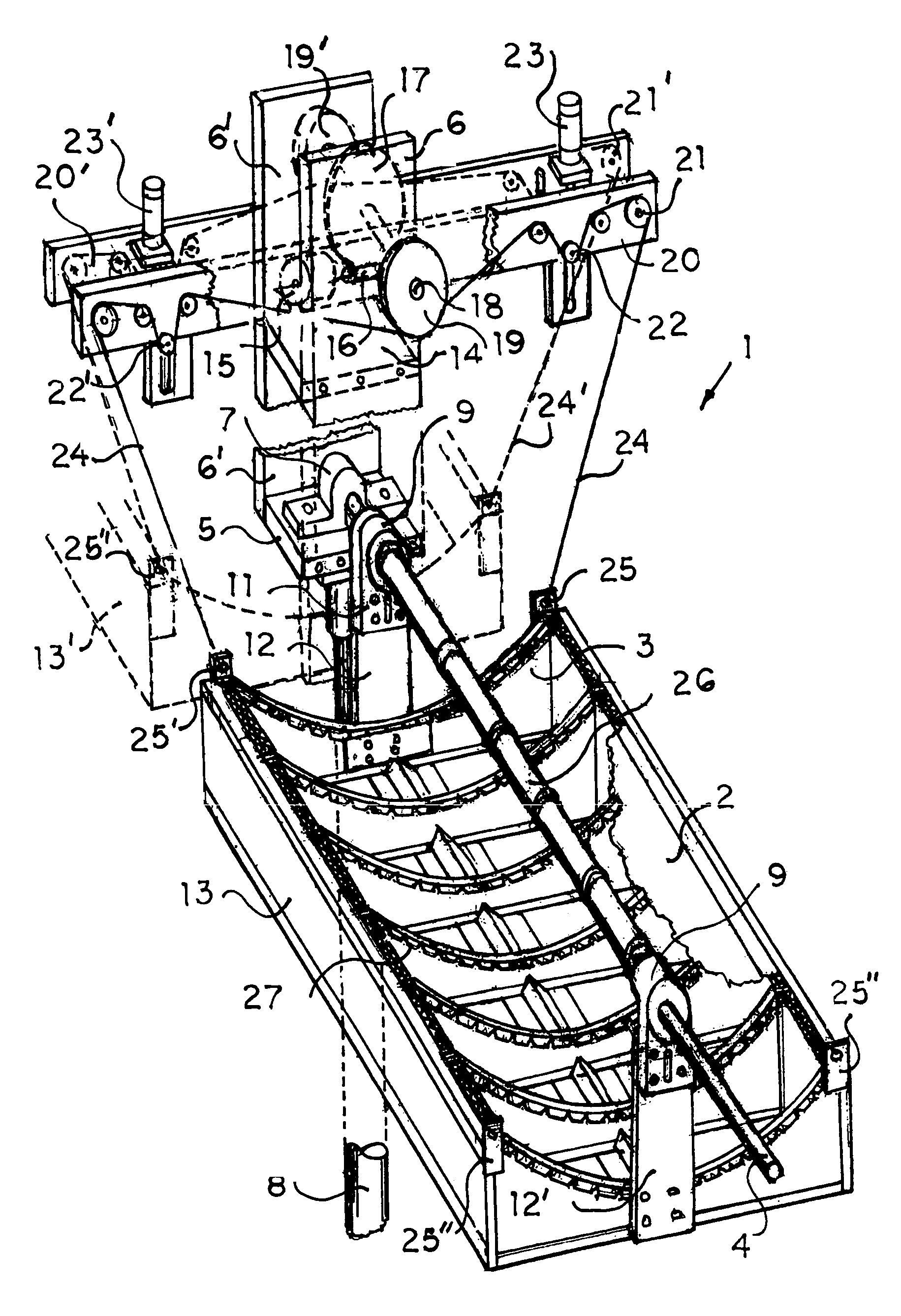

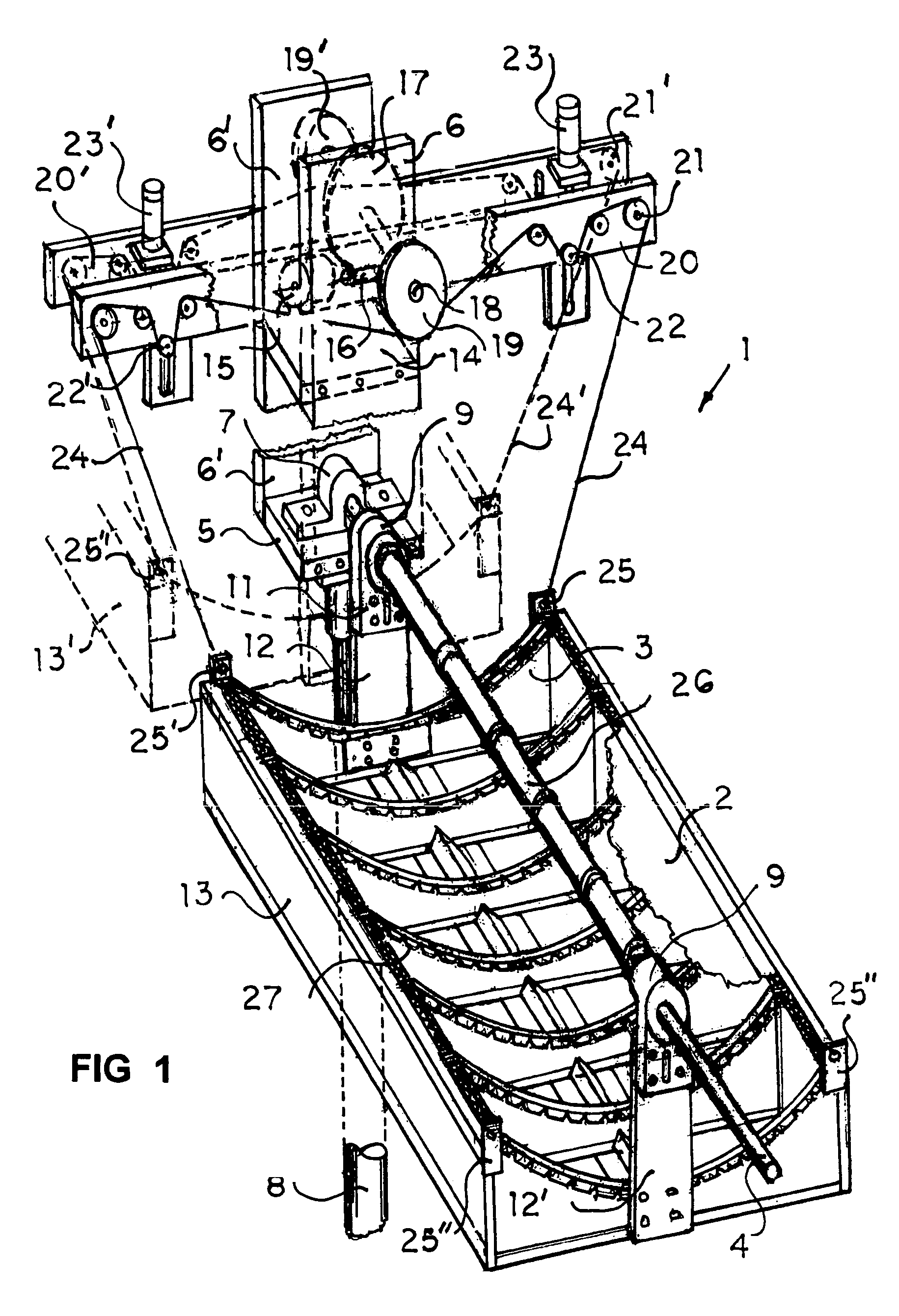

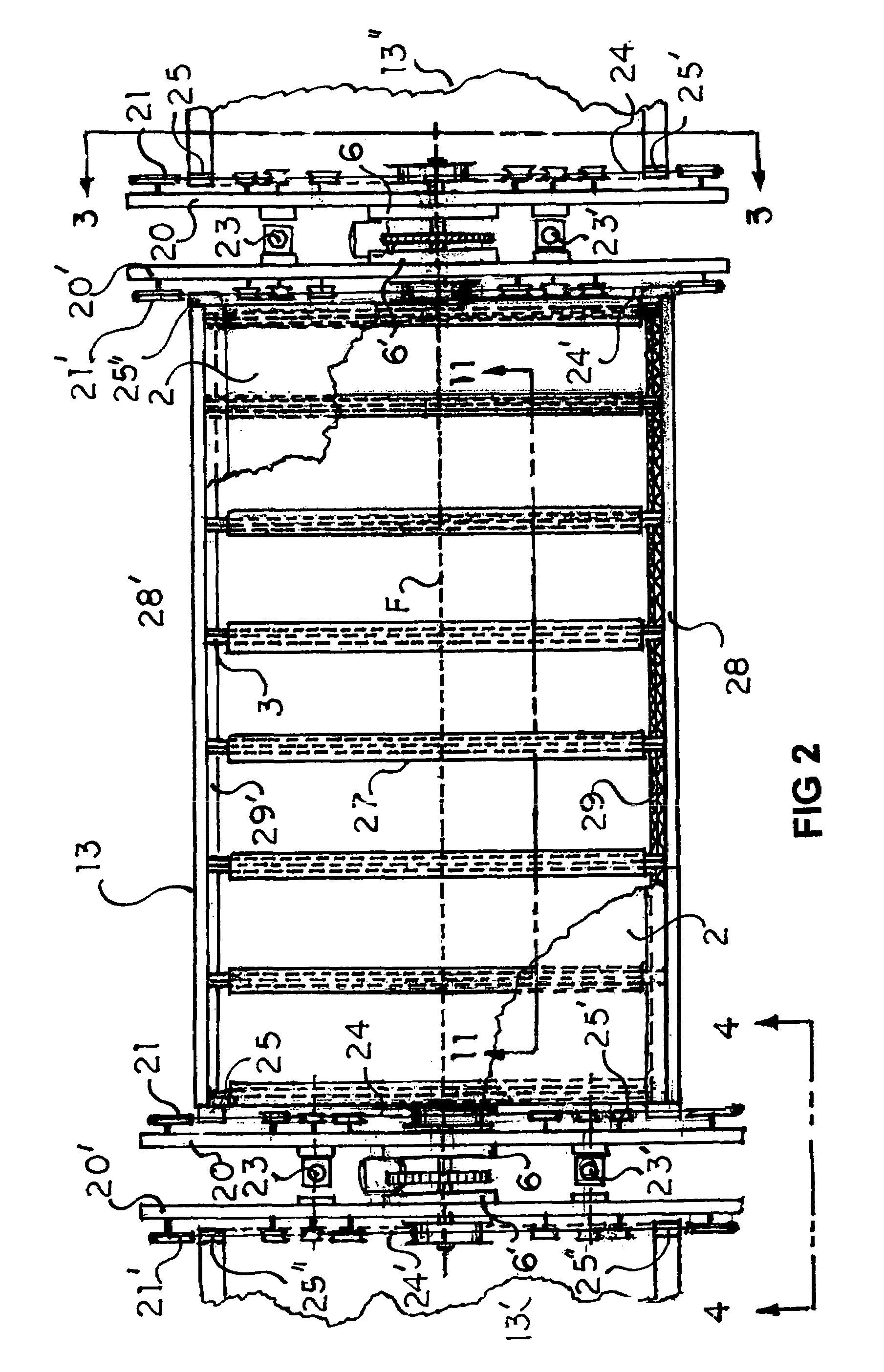

[0036]In FIG. 1, the parabolic trough concentrating collector 1 reflects solar rays from reflector surface 2 (portions cutaway) supported by a plurality of parabolic shaped transversely aligned corrugated board segments 3 with flexible strips 27 superposed and attached to side surfaces (as shown in FIGS. 1, 5, 6).

[0037]Reflected rays are directed to a focal line F co-incident with the centerline of conduit 4 which is secured to cross member 5 of vertically extended support 6 by clamp 7.

[0038]In FIG. 1, support extensions 6, 6′ and cross supports 5, 14 are attached to stationary post 8 and are fixed. Housing 9 with inside bushings 10 include a downwardly extending portion 11 for connection to and support of reflector support arms 12, 12′ which are attached to both ends of unitary reflector 13. The reflector 13, support arms 12, 12′, housing extensions 11, 11′ and housings 9, 9′ pivot from conduit 4.

[0039]In FIG. 1, the upper support extensions 6, 6′ include cross member 14 to support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com