Trench capacitor of a DRAM and fabricating method thereof

a technology of dram and clamp capacitor, which is applied in the direction of semiconductor devices, electrical devices, transistors, etc., can solve the problems of increasing the number of technical problems encountered in the fabrication of both types of dram, limiting and increasing the amount of memory needed to operate software at an alarming rate. , to achieve the effect of increasing the level of device integration and a larger processing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0036]FIGS. 4A through 4E are schematic cross-sectional views showing the steps for fabricating a DRAM according to one preferred embodiment of the present invention. First, as shown in FIG. 4A, a substrate 300 is provided. The substrate has at least an isolation structure 302 formed thereon. The substrate 300 is a silicon substrate and the isolation structure 302 is a shallow trench isolation (STI) structure fabricated using silicon oxide, for example.

[0037]Then, trenches 304a and 304b are formed in the substrate 300 beside the isolation structure 302. The trenches 304a and 304b are formed, for example, by performing a patterning process using a mask layer. In one embodiment, the trenches 304a and 304b penetrate through the isolation structure 302. The dash line portion represents that portion of the isolation structure 302 is removed in the process of forming the trenches 304a and 304b.

[0038]After that, a first lower electrode 306a and a second lower electrode 306b are formed in ...

second embodiment

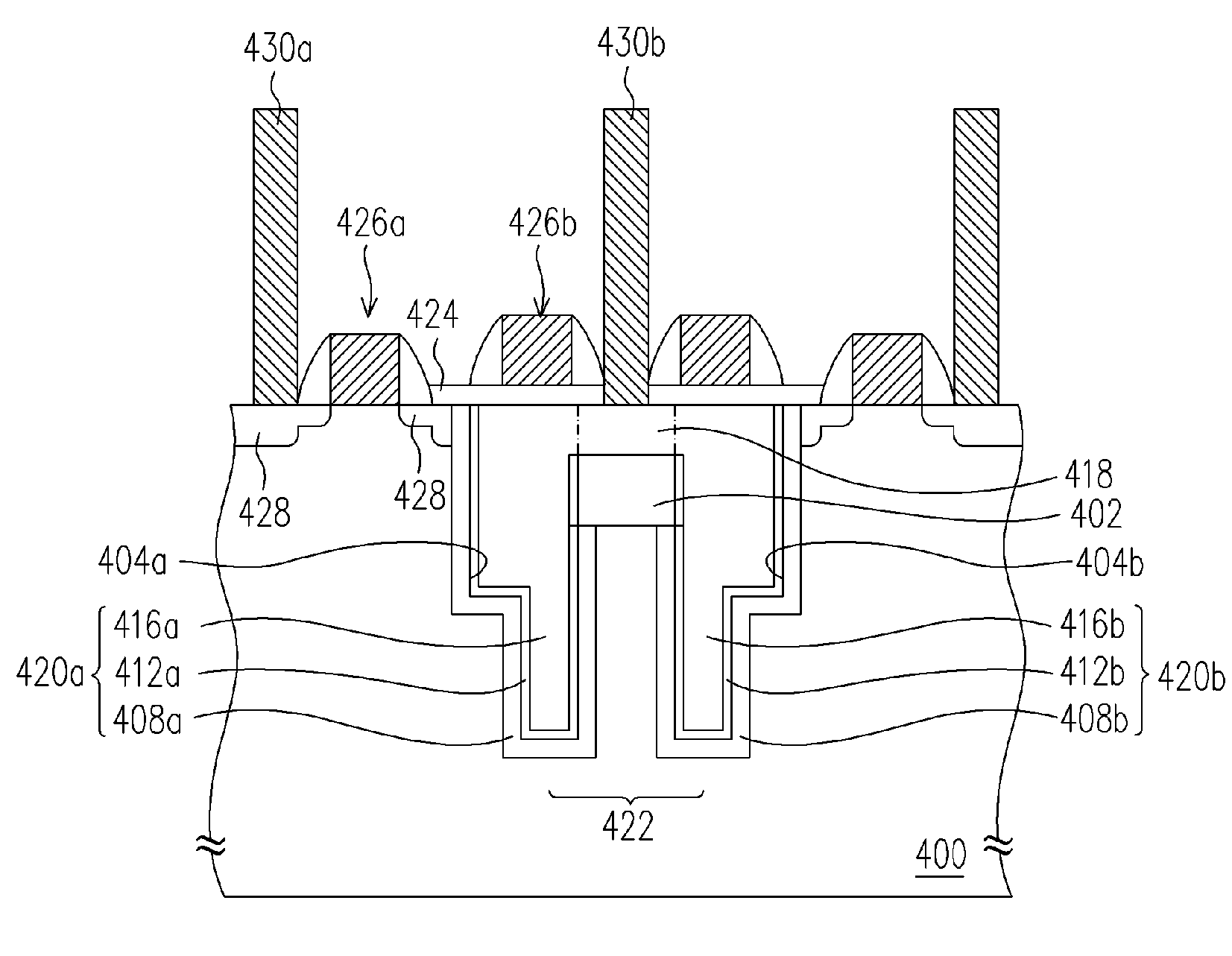

[0048]FIGS. 5A through 5E are schematic cross-sectional views showing the steps for fabricating a DRAM according to another preferred embodiment of the present invention. First, as shown in FIG. 5A, a substrate 400 is provided. The substrate has at least an isolation structure 402 formed thereon. The substrate 400 is a silicon substrate and the isolation structure 402 is a shallow trench isolation (STI) structure fabricated using silicon oxide, for example.

[0049]Trenches 404a and 404b are formed in the substrate 400 beside the isolation structure 402 and then a portion of the isolation structure 402 between the trenches 404a and 404b is removed to form an opening 406. The trenches 404a and 404b and the opening 406 are formed, for example, by performing a patterning process using a mask layer. In one embodiment, the trenches 404a and 404b penetrate through the isolation structure 402. The dash line portion represents that portion of the isolation structure 402 is removed in the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com