Low impact gas spring

a gas spring and low impact technology, applied in the field of gas springs, can solve the problems of increasing the maintenance and repair cost of the press, increasing the need for press maintenance, and impulsing or load spikes of relatively high magnitude and short duration, so as to reduce the impact force, reduce the load, and reduce the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

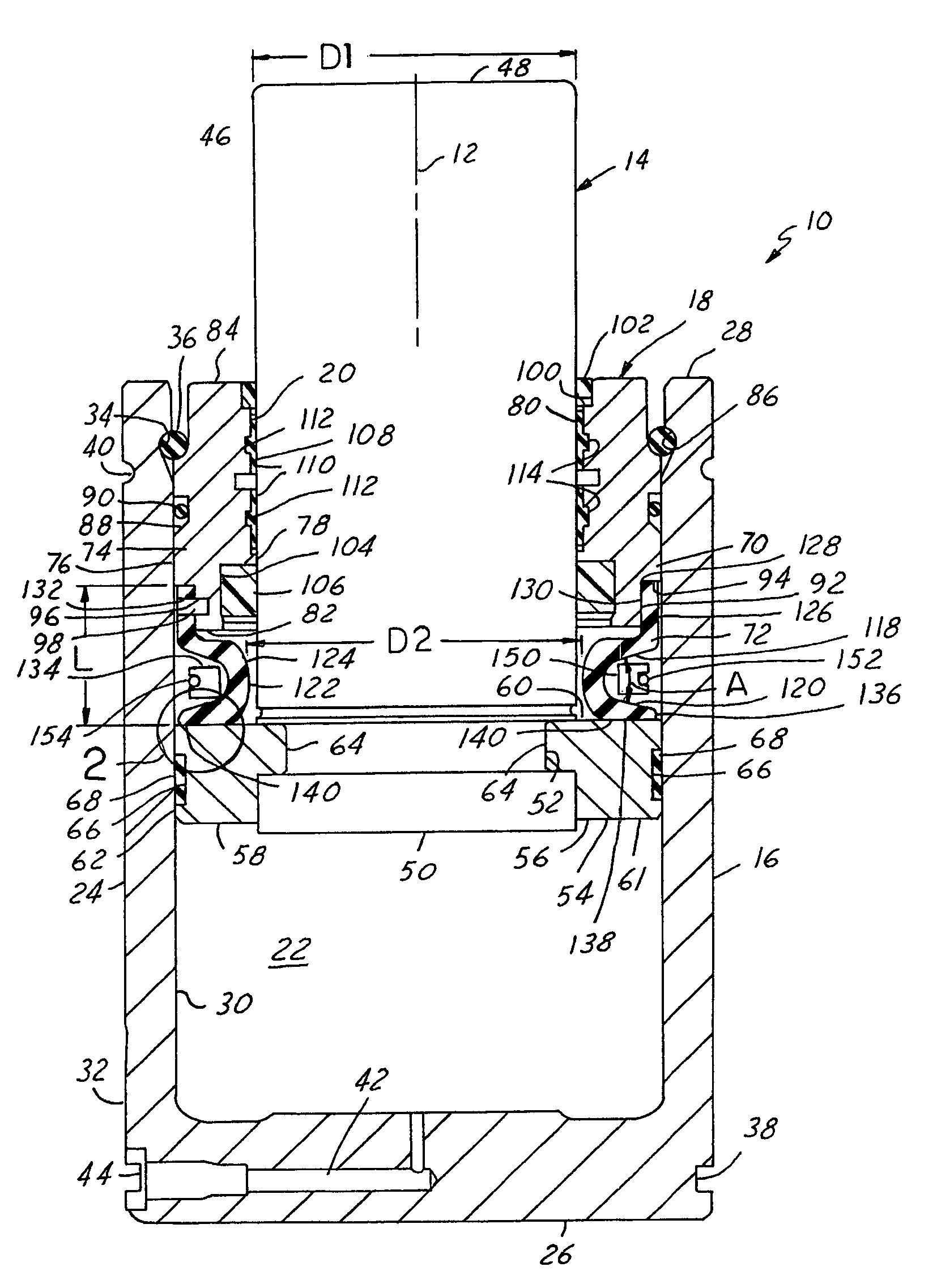

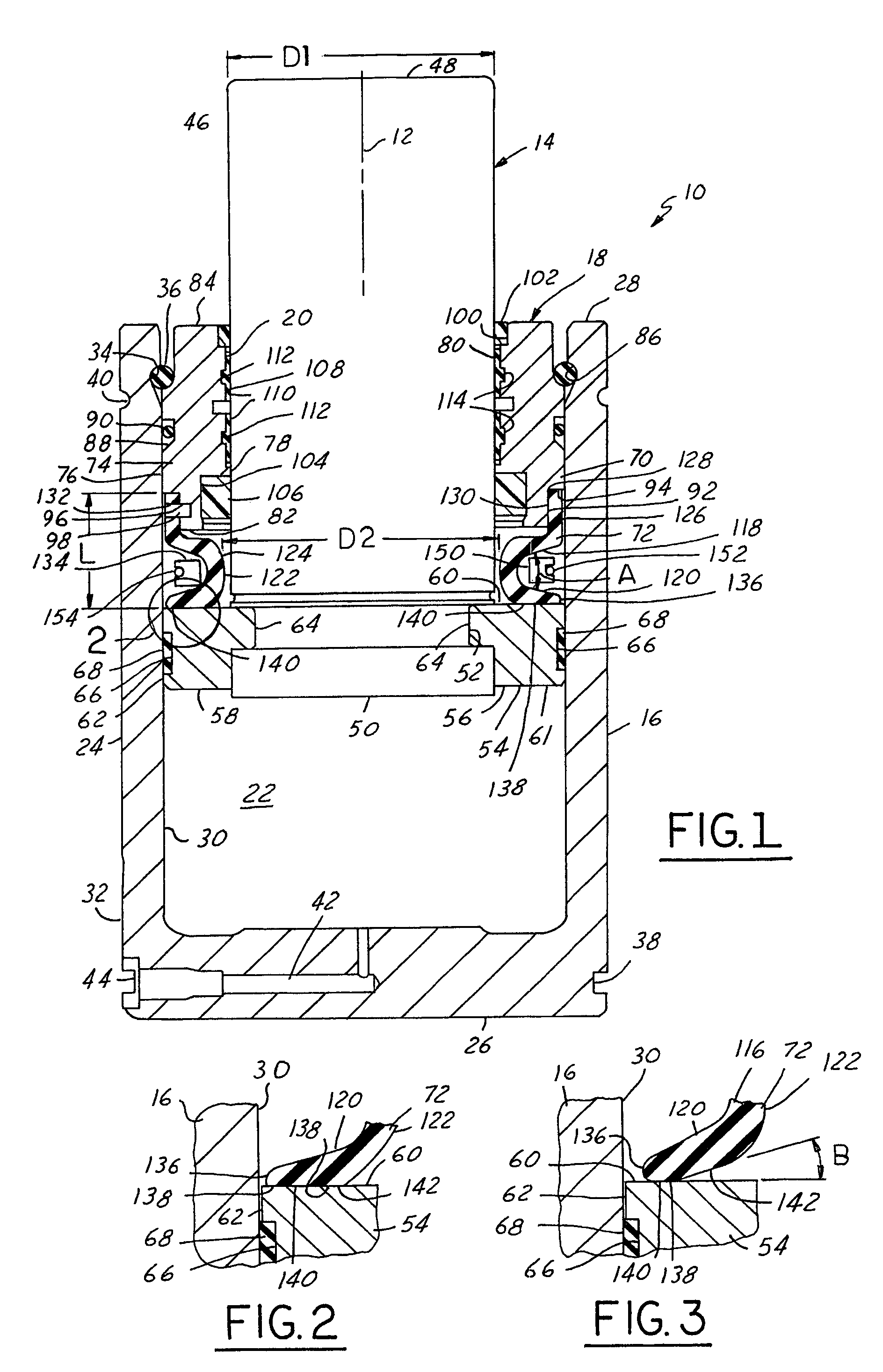

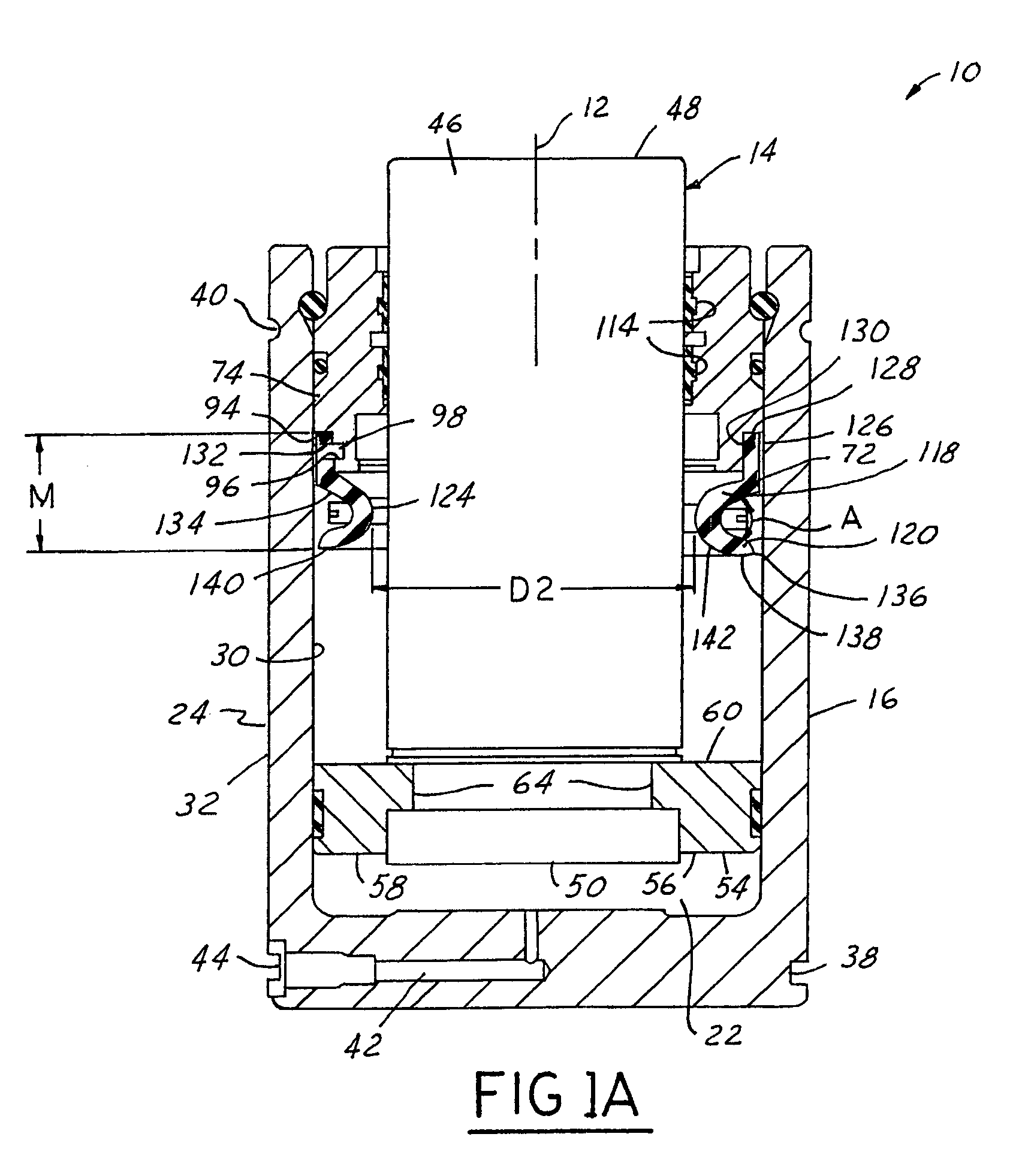

[0019]Referring in more detail to the drawings, FIG. 1 illustrates one presently preferred embodiment of a gas spring 10, such as those used in mechanical presses (not shown). Generally, a plurality of gas springs 10 may be disposed in the mechanical press such that a piston rod assembly 14 of each gas spring 10 is engaged and driven by a ram of the press as the ram advances to form a sheet metal blank in a die assembly of the press. The press may be an eccentric, crank or toggle type mechanical press, for example. Desirably, the force applied to the press ram upon initially moving the piston rod assembly 14 from its extended position toward its retracted position, and also when the press ram is disengaging the piston rod assembly 14 on a return stroke, is reduced. Accordingly, the gas spring 10 reduces the impact force on the press, both during the forming and return strokes of the press, and reduces vibration and noise in operation, thereby enhancing the ability to produce a unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com