Cholesteric liquid crystal light modulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

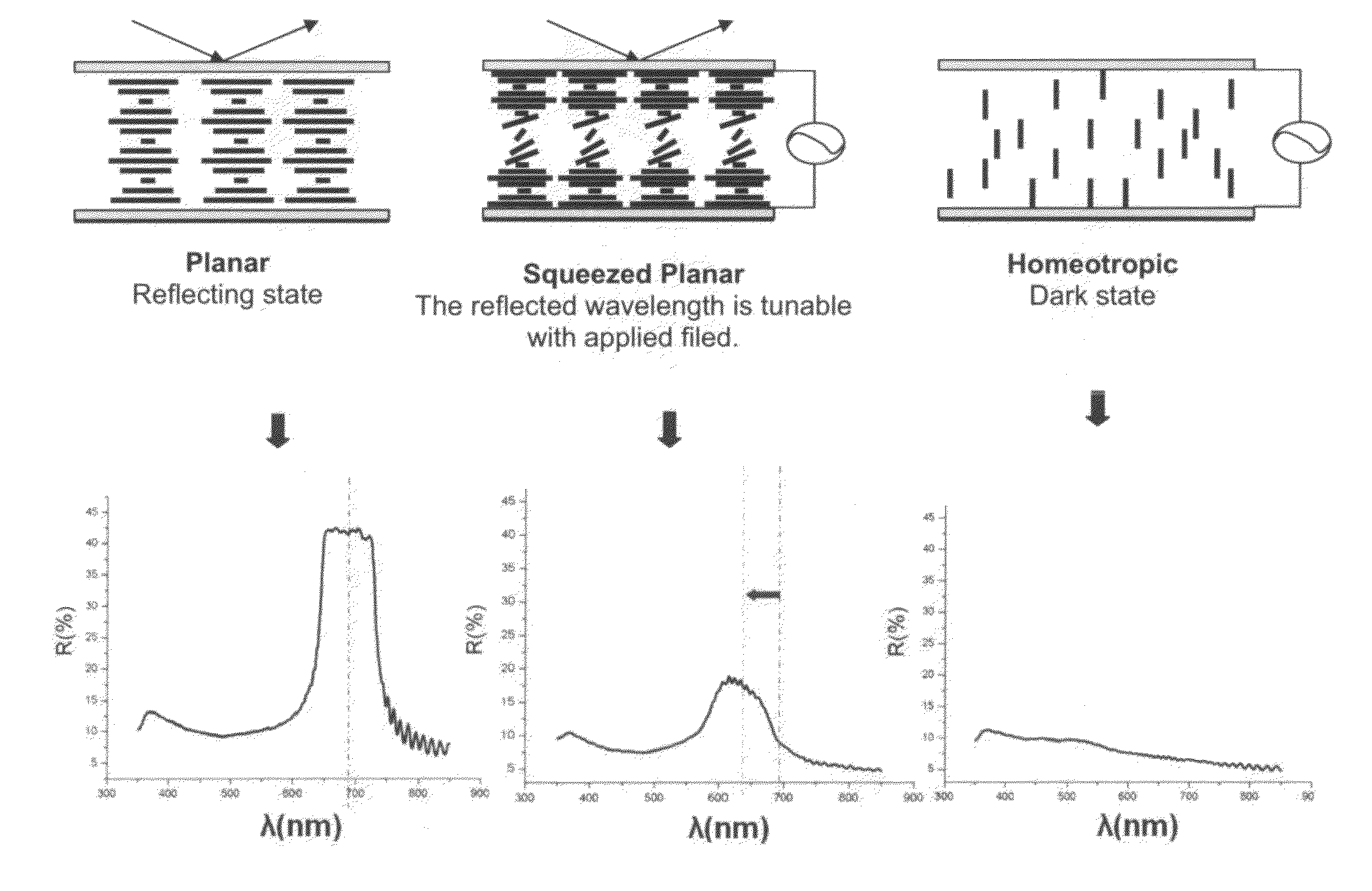

[0032]As shown in FIG. 4, a field-induced blue shift in cholesteric liquid crystal is illustrated wherein the reflected wavelength is a function of applied voltage (a) and the reflectivity is a function of switched spectral wavelength (b). The reflective wavelength of the cholesteric liquid crystal is 695 nm with 45% reflectivity at zero voltage. As the voltage exceeds 15V, the pitches in the bulk are deformed by the voltage because of weak anchoring and thus, the pitches in the middle layers are extended. Consequently, the liquid crystal molecules in the bulk start to compress the pitches near the boundary layers so the pitches near the boundary layers are shortened. The spectral wavelength is switched to reflect a red at 16V with 25% reflectivity, green at 25V with 15% reflectivity and blue color at 40V with 12.5% reflectivity. Because the oriented liquid crystal molecules are no longer in a planar structure, the number of layers contributing to the reflectance decreases. Therefor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com