Optical compensation film, polarizing plate and liquid crystal display device

a liquid crystal display device and optical compensation technology, applied in the direction of polarising elements, thin material processing, instruments, etc., can solve the problem of hardly achieving objects, and achieve the effect of superior image, superior phase difference, and excellent wavelength dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Optical Compensation Film

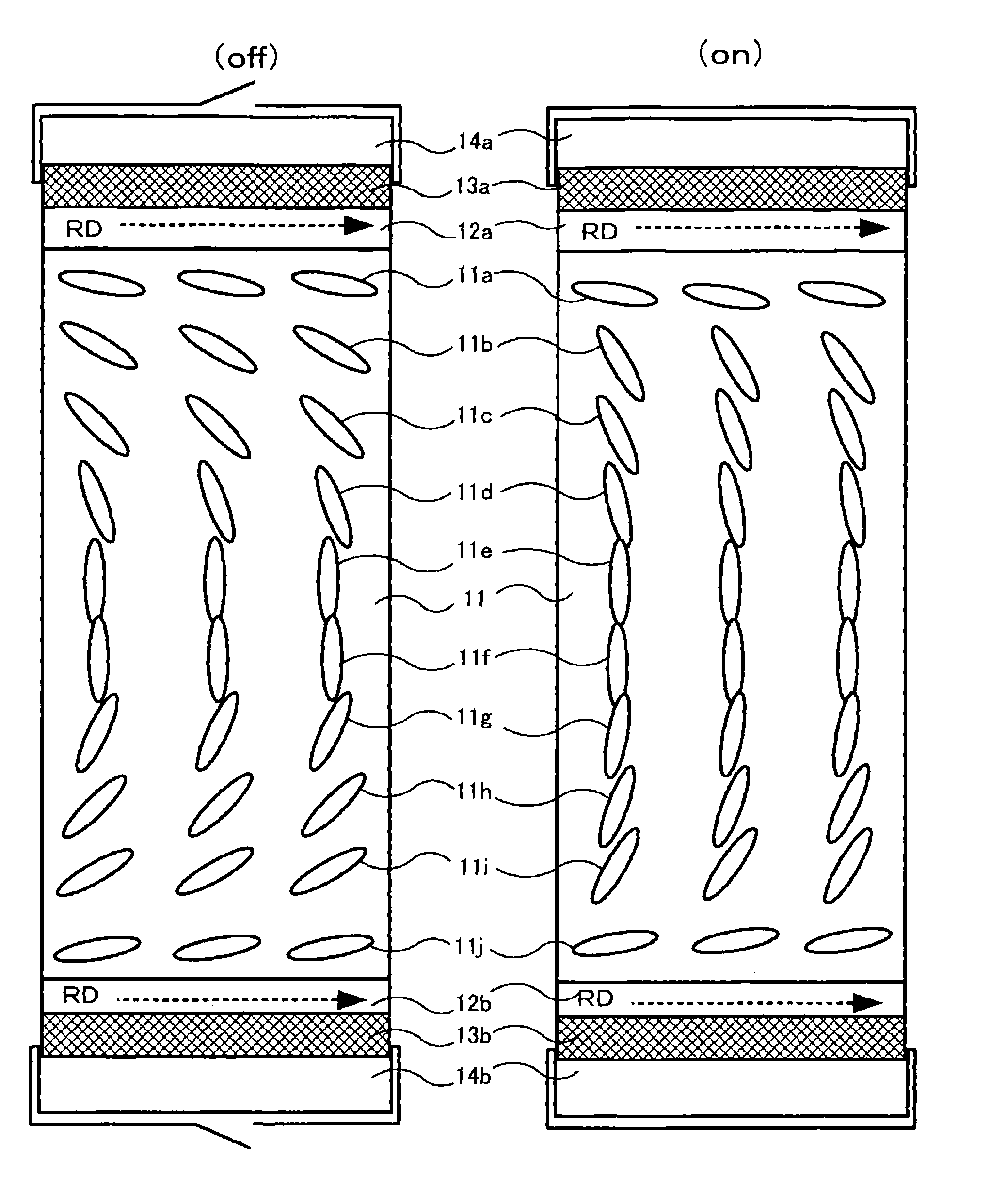

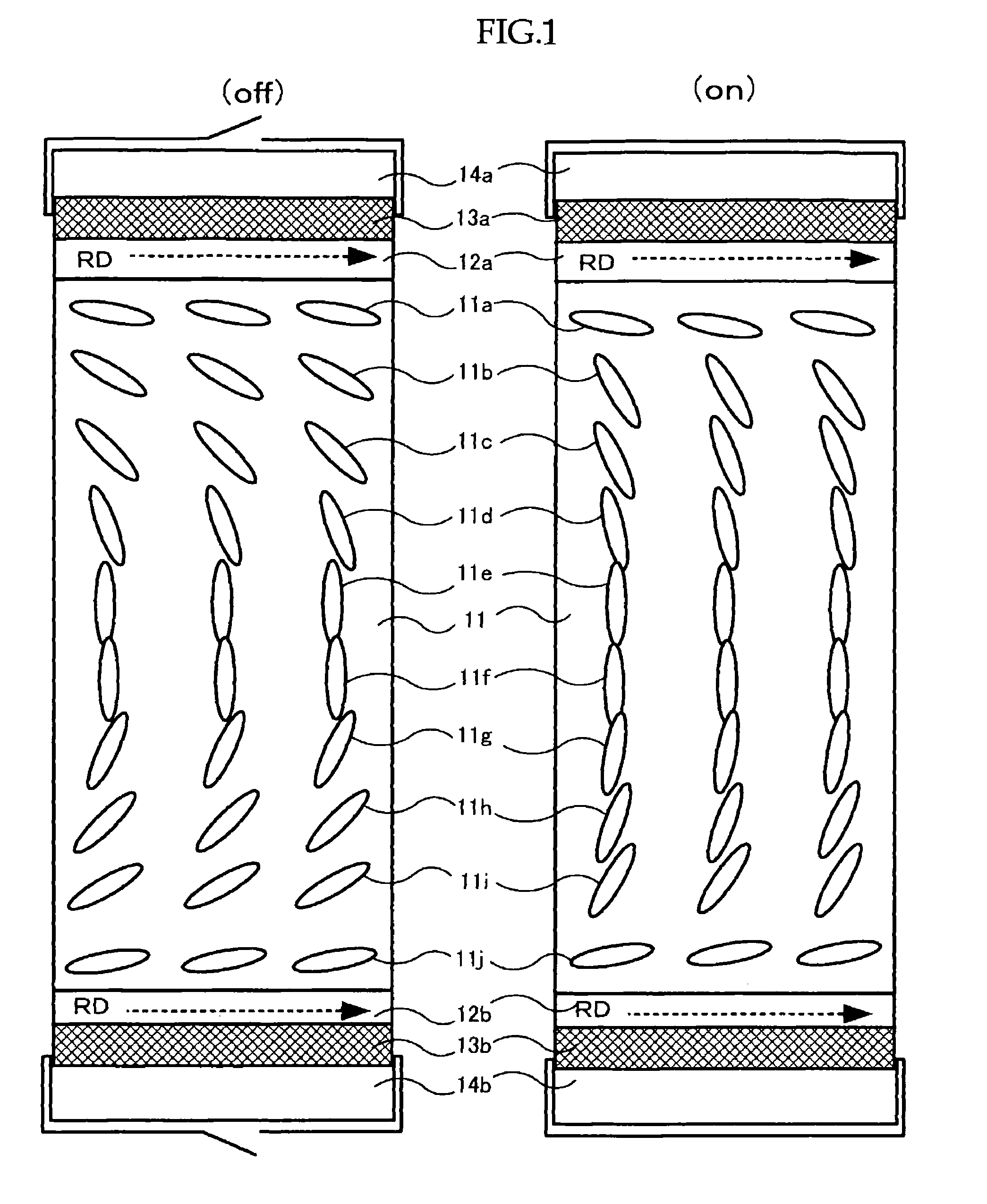

[0082]In the first embodiment, the optical compensation film is one that comprises a first optically anisotropic layer and a second optically anisotropic layer.

[0083]The optical compensation film has a function to solve such a problem of view-angle dependence through compensating phase difference of liquid crystal layers at near substrate interface that transmissivity or brightness changes depending on average orientation of liquid crystal molecules inclined at near substrate interface of liquid crystal devices, briefly speaking, the transmissivity or brightness changes when the view angle changes. The view-angle dependence can be improved, substantially perfect black display can be taken, and front contrast ratio can be increased by way of disposing the inventive optical compensation film at interface with substrates of the liquid crystal display devices.

[0084]In the inventive optical compensation film, the view-angle dependence can be improved by both opti...

second embodiment

Optical Compensation Film

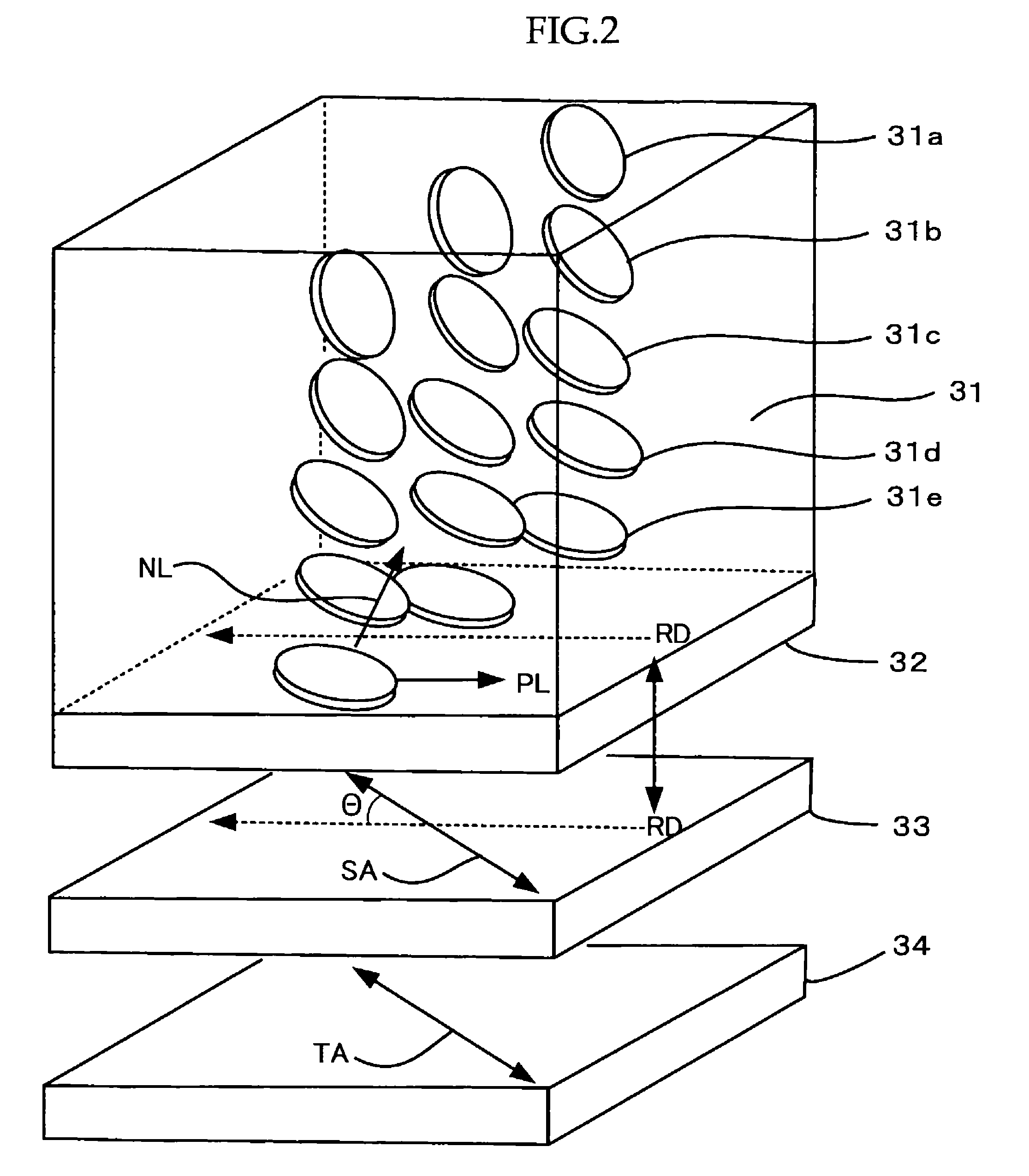

[0389]The optical compensation films of the second embodiment comprise an orientation film and an optically anisotropic layer containing a liquid-crystal compound.

[0390]The optical compensation films comprise at least two layers of, for example, a cellulose acylate film and an optically anisotropic layer having an in-plane anisotropy, preferably further comprise an orientation film to control the orientation of liquid-crystal compounds between the cellulose acylate film and the optically anisotropic layer. The cellulose film and the optically anisotropic layer may be of two or more sheets respectively. The “cellulose acylate film” encompasses cellulose acetate films.

[0391]The difference Δγsd between γsd(AL) and γsd(LC) is no less than −4.0 erg / cm2, wherein γsd(AL) is a dispersion force component of surface free energy of orientation film (AL), γsd(LC) is a dispersion force component of surface free energy of liquid-crystal compound (LC), and Δγsd is calculat...

third embodiment

Optical Compensation Film

[0459]The optical compensation films of the third embodiment have an optically anisotropic layer formed by polymerizing and curing a composition, in which the composition comprises at least a liquid crystal compound, and the ratio of GPC pattern area, in a range of above 5000 of molecular weight in GPC chart after maintaining at 60° C. and 60% of relative humidity for three days, to entire GPC pattern area is no more than 0.1% (polystyrene conversion).

[0460]The GPC chart means the chart in which GPC is measured by the conditions and apparatuses described in GPC measurement method described below.

[0461]GPC pattern area in a range of above 5000 of molecular weight means the area that is represented as having molecular weights of no less than 5000 in polystyrene conversion from elution period and detected strength of elution pattern; the entire GPC pattern area means the area of entire elution pattern on GPC chart.

GPC Measuring Process

[0462](i) A sample is weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inclination angle | aaaaa | aaaaa |

| surface free energy | aaaaa | aaaaa |

| liquid crystal temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com