Method and system for controlling an electric motor with variable switching frequency at variable operating speeds

a technology of electric motors and operating speeds, applied in the direction of motor/generator/converter stoppers, dynamo-electric converter control, pulse technique, etc., can solve the problems of increasing the switching loss of inverters, increasing the data processing burden of data processors or digital signal processors within inverters, and reducing the life of inverters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

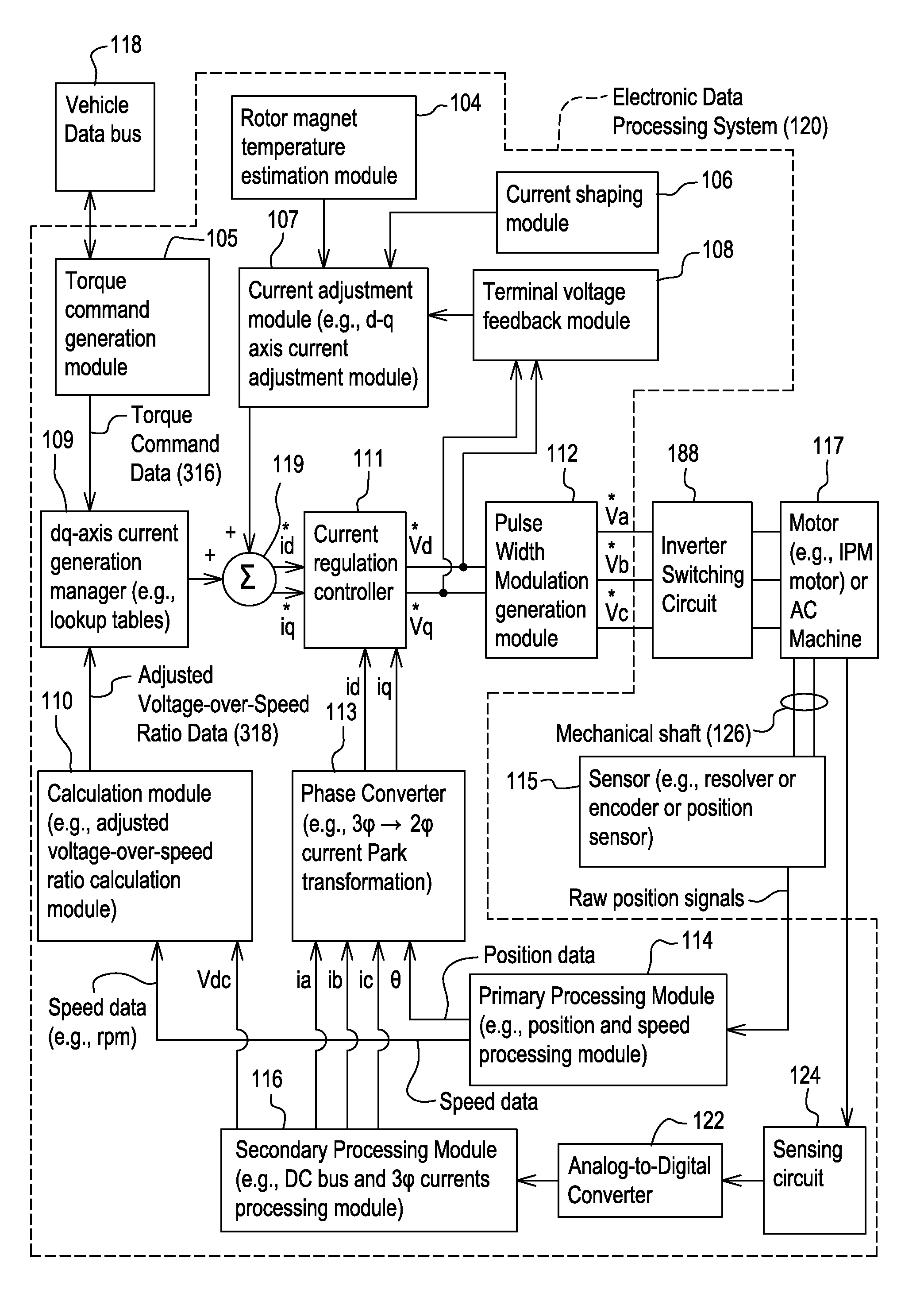

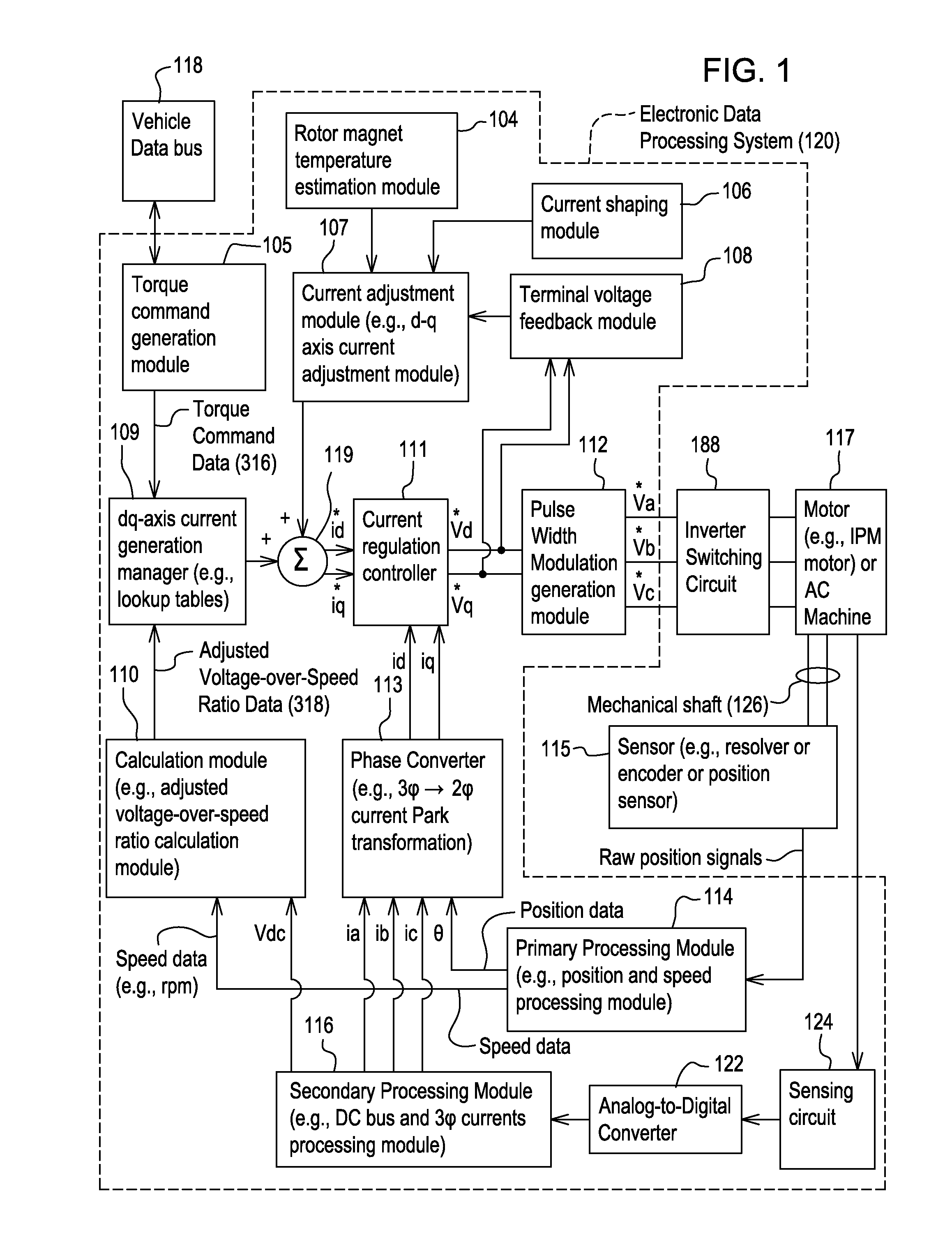

[0011]In accordance with one embodiment, FIG. 1 discloses system for controlling a motor 117 (e.g., an interior permanent magnet (IPM) motor) or another alternating current machine. The method and system described in this document can be equally applied to, interior permanent magnet motors, induction machines, or surfaced mounted permanent magnet (PM) machines with wide operating speeds. In one embodiment, the system, aside from the motor 117, may be referred to as an inverter or a motor controller. The system or inverter is well-suited for a widely varying operating speed of the motor shaft such that a balanced or optimum pulse width modulation frequency is selected for the inverter in one or more different speed ranges.

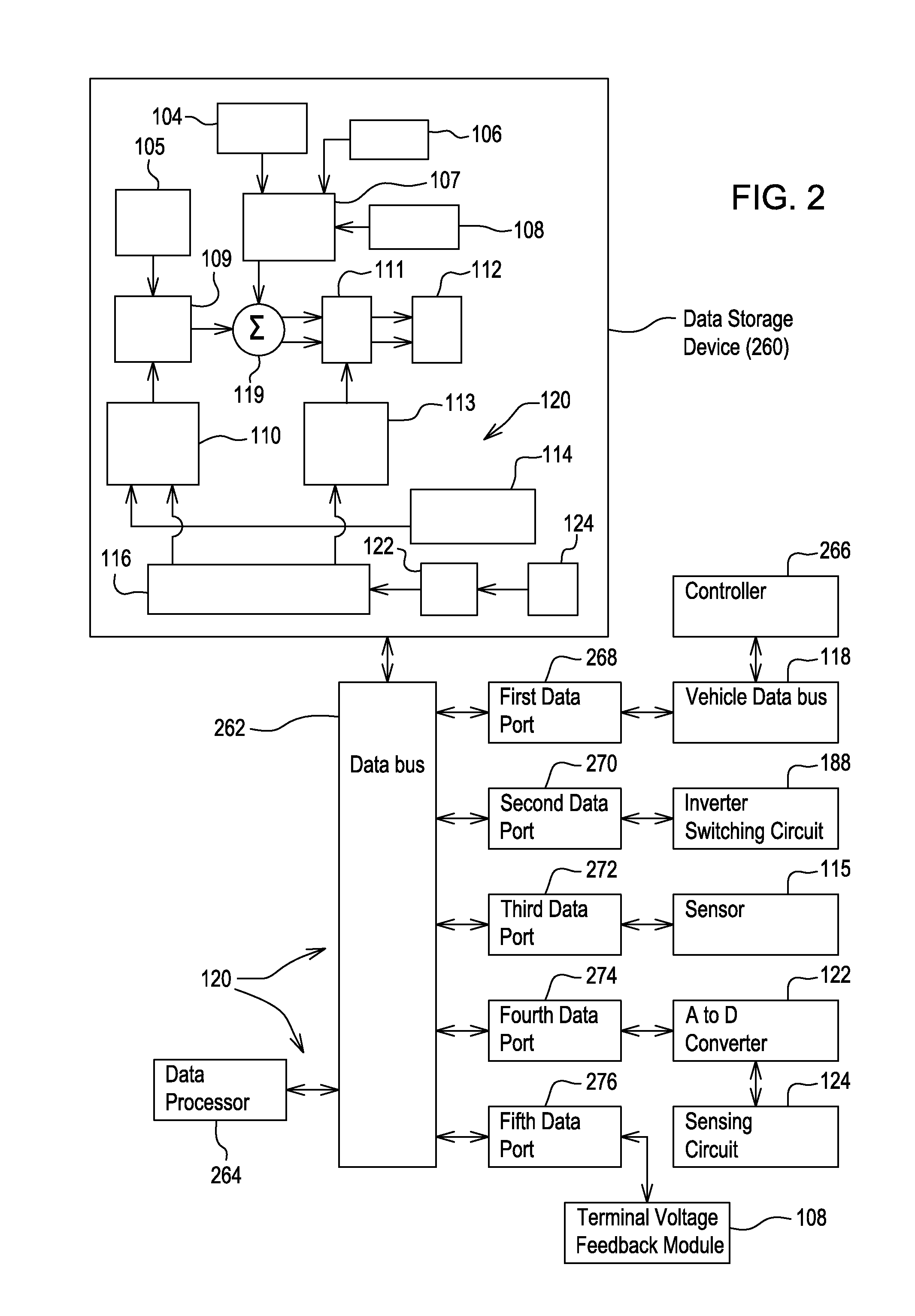

[0012]The system comprises electronic modules, software modules, or both. In one embodiment, the motor controller comprises an electronic data processing system 120 to support storing, processing or execution of software instructions of one or more software modules....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com