Positive photosensitive resin composition and method for forming patterns by using the same

a technology of resin composition and photosensitive resin, which is applied in the direction of photomechanical equipment, instruments, optics, etc., can solve the problems of reducing the resolution of the subsequent lithography process, the photoresist layer cannot block the reflected light of the metal circuit, and the photoresist pattern adhered to the metal circuit is easily decolored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

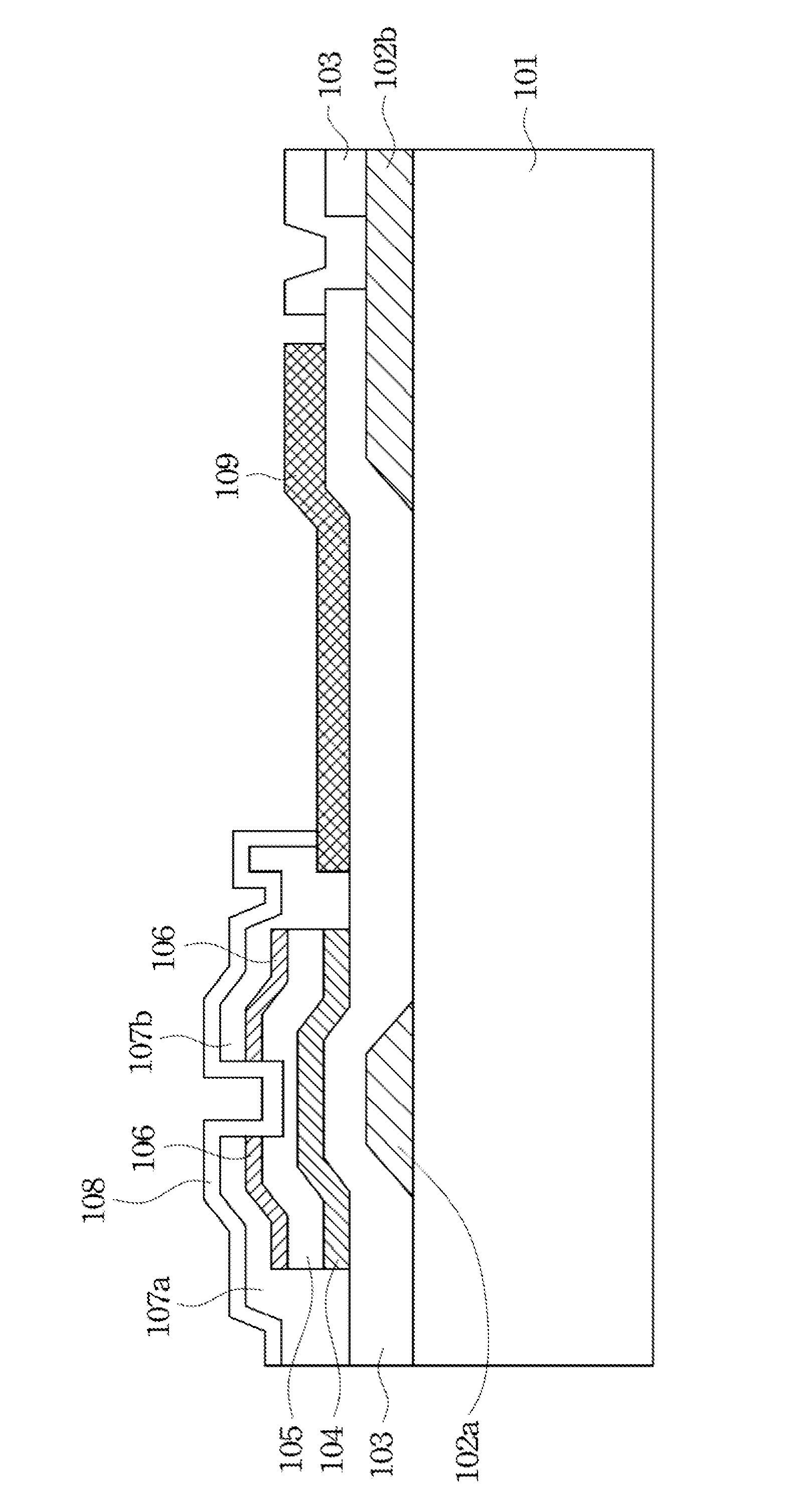

Image

Examples

synthesis example a-1-1

[0109]A 1000 mL four-necked conical flask equipped with a nitrogen inlet, a stirrer, a heater, a condenser and a thermometer was purged with nitrogen, and the following components were charged to the flask. The aforementioned components comprising 0.70 moles of m-cresol, 0.30 moles of p-cresol, 0.5 moles of 3,4-dihydroxybenzaldehyde and 0.020 moles of oxalic acid were stirred slowly and heated to 100° C., so as to carry out polycondensation for 6 hours. Next, the reaction was heated again to 180° C. and then dried under a decreased pressure at 10 mmHg for evaporating the solvent, thereby obtaining a hydroxy-type novolac resin (A-1-1).

synthesis examples a-1-2

to A-1-5

[0110]Synthesis Examples A-1-2 to A-1-5 were practiced with the same method as in Synthesis Example A-1-1 by using different kinds and different amounts of the components of the hydroxy-type novolac resin (A-1). The formulations of Synthesis Examples A-1-2 to A-1-5 were also listed in TABLE 1 rather than focusing or mentioning them in details.

synthesis examples a-2-1

to A-2-3

[0111]Synthesis Examples A-2-1 to A-2-3 were practiced with the same method as in Synthesis Example A-1 by using different kinds and different amounts of the components of the other hydroxy-type novolac resin (A-2). The formulations of Synthesis Examples A-2-1 to A-2-3 were also listed in TABLE 1 rather than focusing or mentioning them in details.

Preparation of Positive Photosensitive Resin Composition

[0112]The following examples are directed to the preparation of the positive photosensitive resin composition of Examples 1 to 13 and Comparative Examples 1 to 6 according to TABLES 2 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com