Surface-acoustic-wave filters with poles of attenuation created by impedance circuits

a technology of impedance circuit and surface acoustic wave, which is applied in the direction of multiple-port network, electrical apparatus, and electromechanical/electrostrictive/magnetostrictive devices, etc., can solve the problems of difficult to meet the above requirements satisfactorily with a saw ladder filter, difficult to provide wide stopbands with the necessary high attenuation, and difficult to solve. , to achieve the effect of improving the frequency characteristic of the filter, increasing the stopband

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

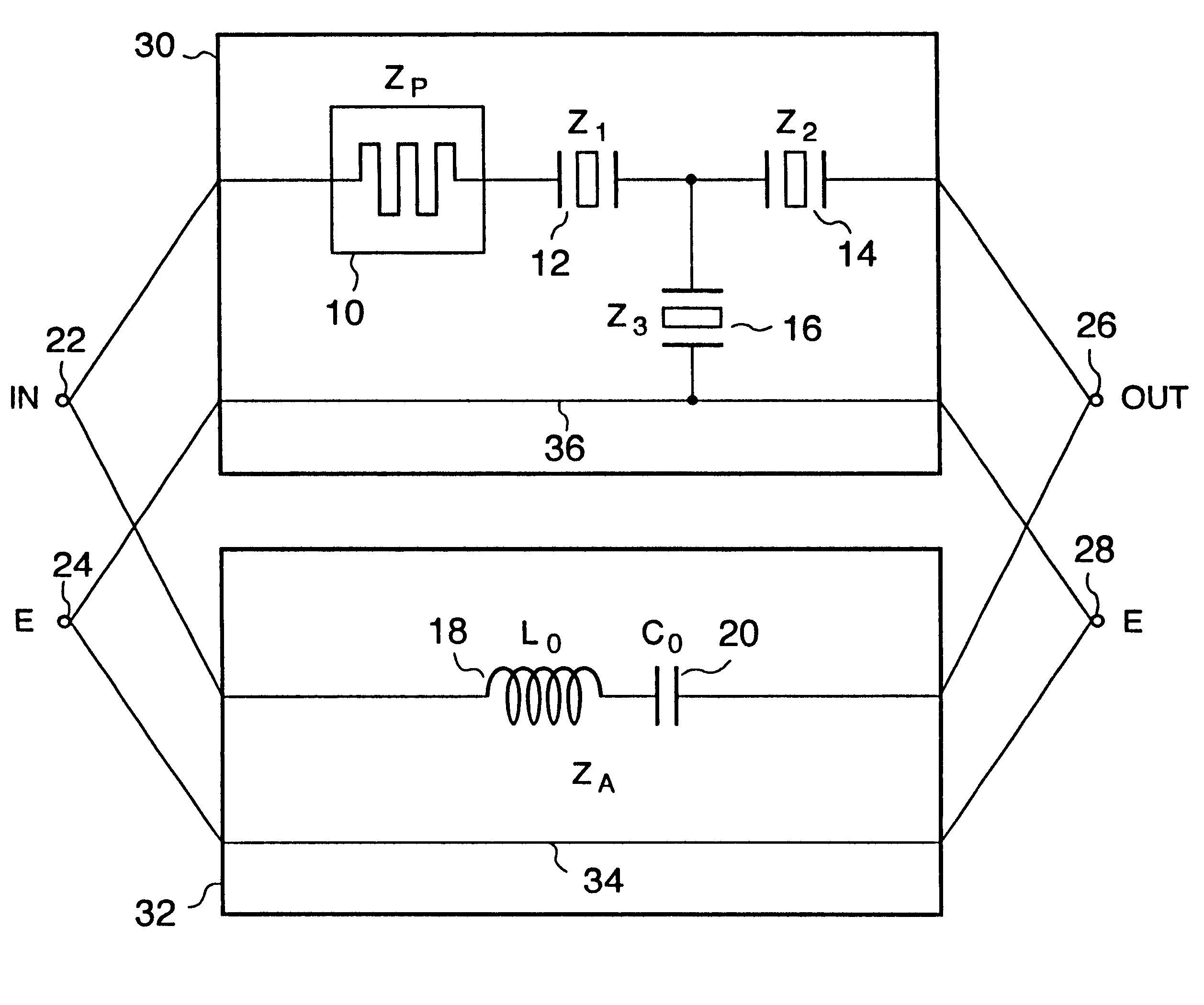

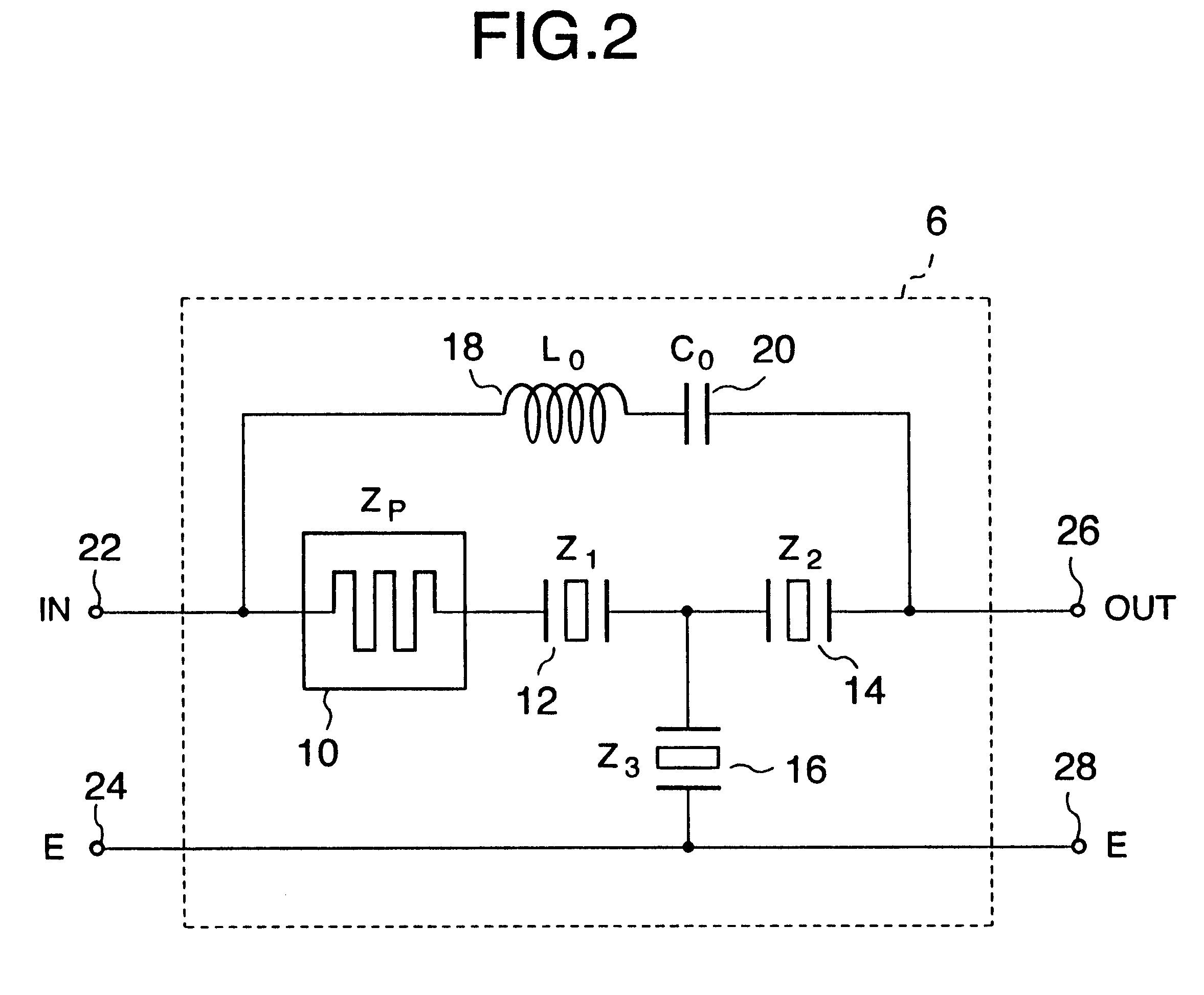

The first embodiment of the invention is a SAW filter suitable for use as the receiving filter 6 in FIG. 1. Referring to FIG. 2, this embodiment of the receiving filter 6 comprises a phase shifter 10, a pair of series-arm SAW resonators 12 and 14, a shunt-arm SAW resonator 16, an inductor 18, and a capacitor 20. These elements form a two-port circuit, the input port comprising an input terminal 22 and ground or earth (E) terminal 24, and the output port comprising an output terminal 26 and ground terminal 28.

The phase shifter 10 and series-arm SAW resonators 12 and 14 are coupled in series between the input terminal 22 and output terminal 26. The inductor 18 and capacitor 20 are also coupled in series between the input terminal 22 and output terminal 26, in parallel with the phase shifter 10 and series-arm SAW resonators 12 and 14. The shunt-arm SAW resonator 16 is coupled, on one side, to a node disposed between the two series-arm SAW resonators 12 and 14, and on the other side to ...

second embodiment

To improve the stopband attenuation characteristics, further SAW resonators can be added as shown in FIG. 7. As in the first embodiment, the impedance circuit comprises an inductor 18 with an impedance L.sub.O of 3.0 nH, and a capacitor 20 with a capacitance C.sub.O of 0.1 pF. The phase shifter 10 is again an 11-cm stripline. Each of the series-arm SAW resonators 12, 14, and 38 comprises an interdigital transducer with one hundred pairs of electrode fingers and an aperture of 50 .mu.m. As in the first embodiment, the inductor 18 and capacitor 20 are coupled in parallel with the phase shifter 10 and the first pair of series-arm SAW resonators 12 and 14.

The second embodiment has four shunt-arm SAW resonators 40, 42, 44, and 46, which are coupled in a ladder configuration with the series-arm SAW resonators. The first and last shunt-arm SAW resonators 40 and 46 each have an interdigital transducer with sixty pairs of electrode fingers and an aperture of 60 .mu.m. The two inner shunt-arm...

third embodiment

The third embodiment is designed so that this condition is satisfied over a wide range of high frequencies, as will be illustrated below.

For comparison, FIG. 15 shows a conventional SAW filter lacking the inductor 58 of the third embodiment. FIG. 16 shows the corresponding equivalent lumped-constant circuit representation. The circuit constants in FIG. 16 are the same as the corresponding constants in FIG. 13.

Graphs of the open-circuited impedance Z.sub.O and short-circuited impedance Z.sub.S of this conventional SAW filter are shown in FIG. 17. The horizontal axis indicates frequency in hertz (Hz); the vertical axis indicates impedance in ohms (.OMEGA.). Z.sub.O and Z.sub.S were calculated from equations (7) to (11) with L.sub.O set equal to zero. The difference between Z.sub.O and Z.sub.S in the frequencies above about 875 MHz should be noted, as these frequencies are located in the desired upper stopband of the filter.

FIG. 18 shows the open-circuited impedance Z.sub.O and short-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com