Ultraviolet detector

a detector and ultra-violet technology, applied in the field of ultra-violet detectors, can solve the problems of lowering the breakdown voltage, affecting and affecting the accuracy of the detector, so as to achieve the effect of reducing the stability and reliability of the detector and increasing the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

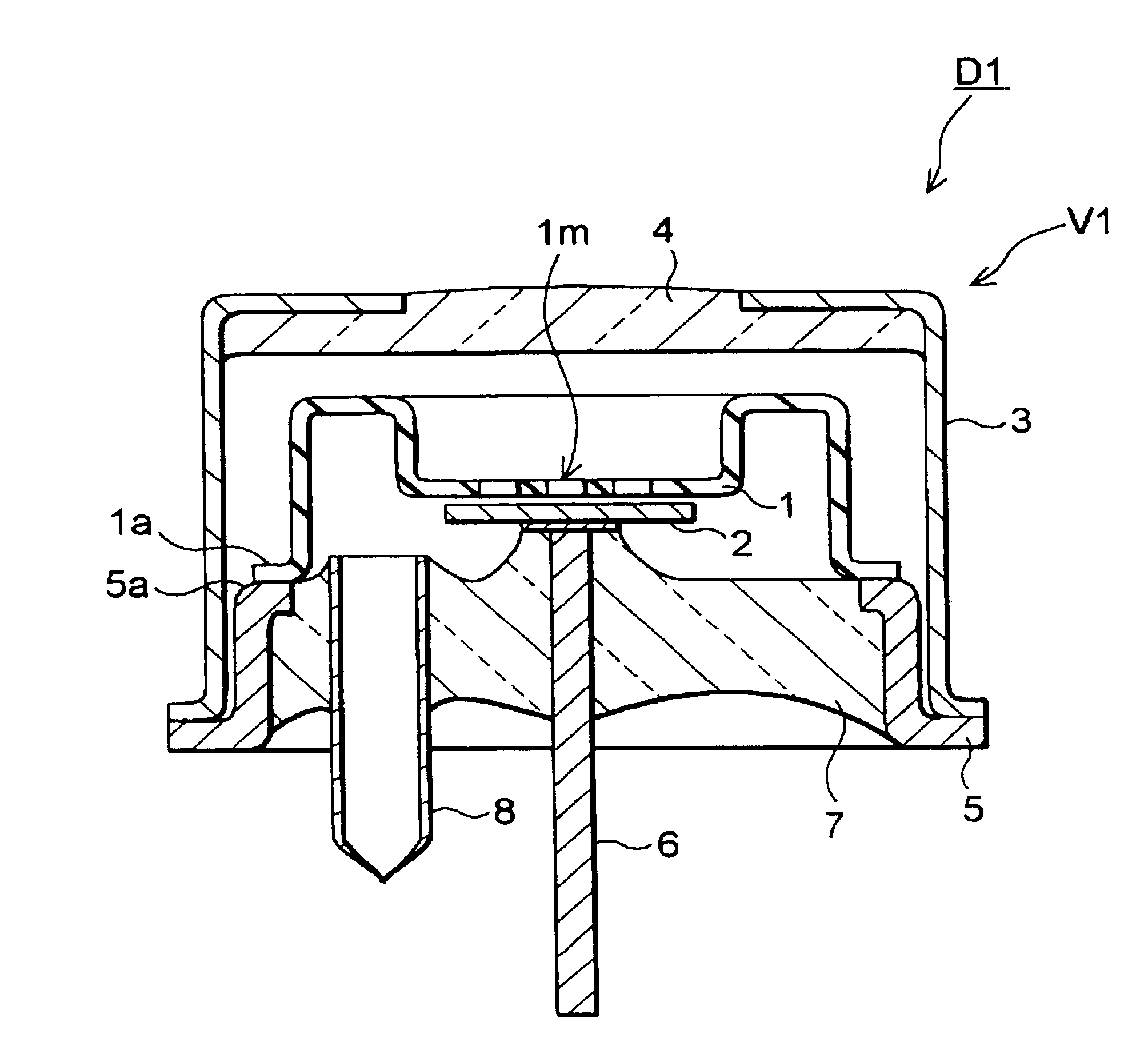

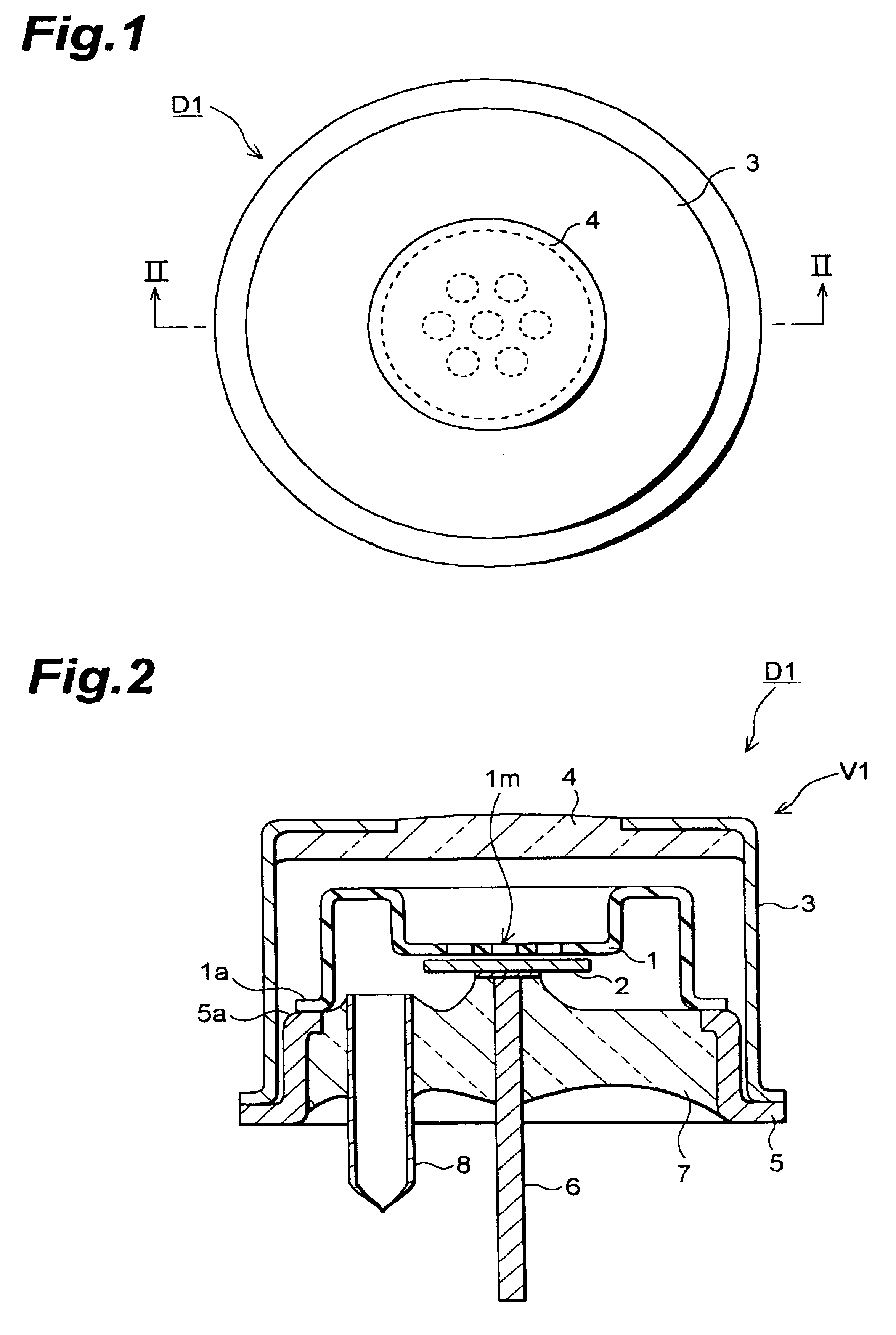

FIG. 1 is a plan view of an ultraviolet detector D1 in accordance with the present invention. FIG. 2 is a sectional view of the ultraviolet detector D1 taken along line II--II of FIG. 1. This detector comprises a sealed vessel V1, and an anode 1 and a cathode 2 which are disposed within the sealed vessel V1.

The sealed vessel V1 comprises a tubular member 3, made of a metal material blocking ultraviolet radiation, having two openings; a window member 4, made of an ultraviolet-transparent glass material, closing one of the openings of the tubular member 3; a ring-shaped metal member 5 secured to the tubular member 3 so as to close the other opening of the tubular member 3; and a glass sealant 7 sealing the opening in the ring-shaped metal member 5. The lower side wall portions of the tubular member 3 and ring-shaped metal member 5 are curved so as to project outward, and their curved portions are electrically welded together so as to overlap each other. The middle side wall portion of...

second embodiment

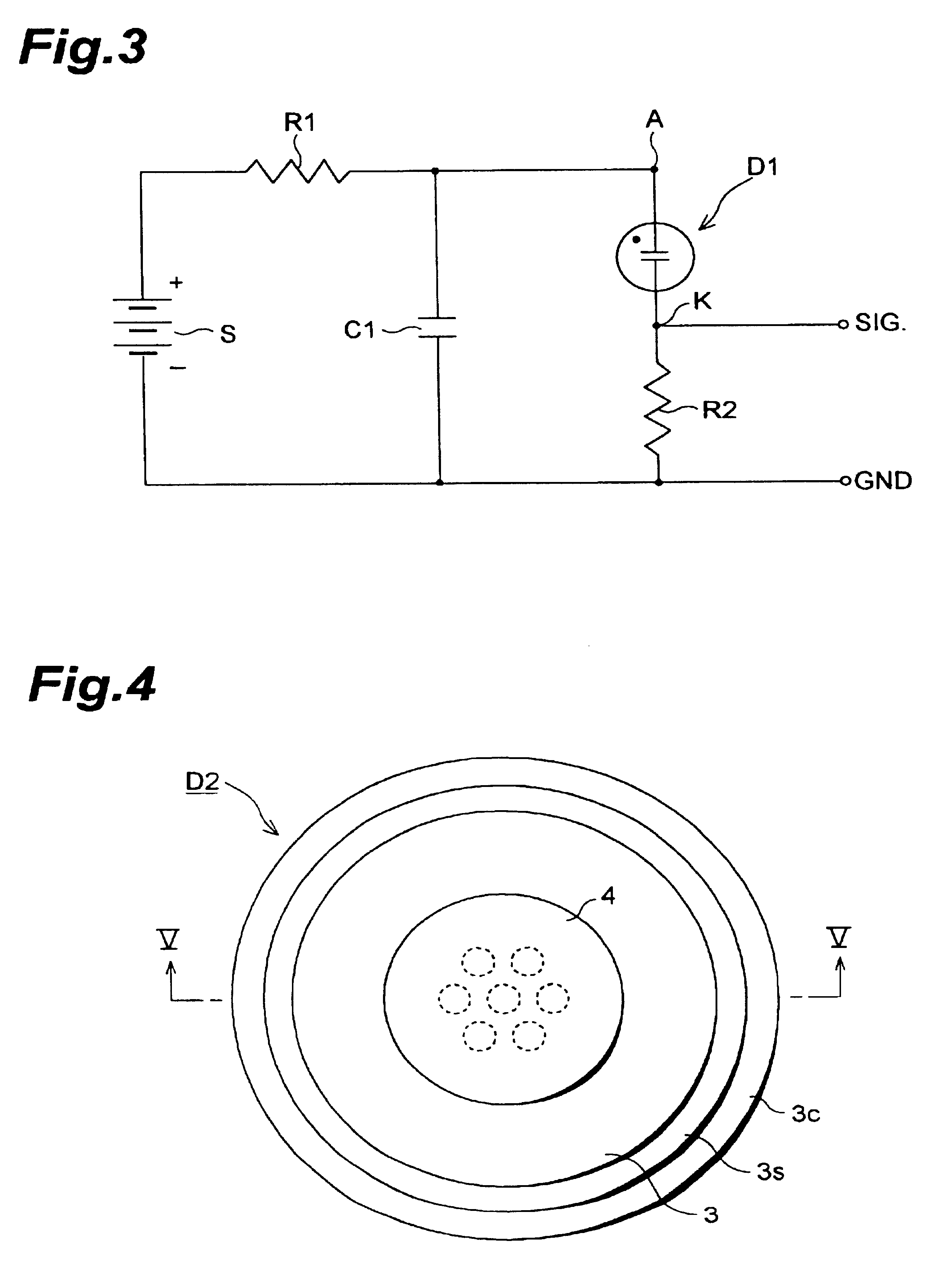

In the following, an ultraviolet detector D2 in accordance with the present invention will be explained. FIG. 4 is a plan view showing the ultraviolet detector D2. FIG. 5 is a sectional view of the ultraviolet detector D2 taken along line V--V of FIG. 4. This detector differs from that shown in FIGS. 1 and 2 only in the configurations of the upper part of the tubular member 3 and the anode 1. The diameter of the tubular member 3 differs between the upper part and lower part of the outer wall in its axial direction. Namely, the upper part of the outer wall has a diameter smaller than that of the lower part thereof, whereby their inner faces form a step 3s at the boundary therebetween. The step 3s of the inner face of the tubular member 3 has a lower surface 3b in parallel with the window member 4. Welded to the lower surface 3b of the step 3s is the upper surface of the outer edge of the planar anode 1. The distance between the upper surface 3c of the flange at the lower end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com