Agricultural methods with superheated steam

a technology of superheated steam and agricultural methods, applied in soil-working methods, agriculture tools and machines, insect catchers and killers, etc., can solve the problems of high labor intensity, low yield, and difficulty in reducing the drying time of berries, so as to reduce the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

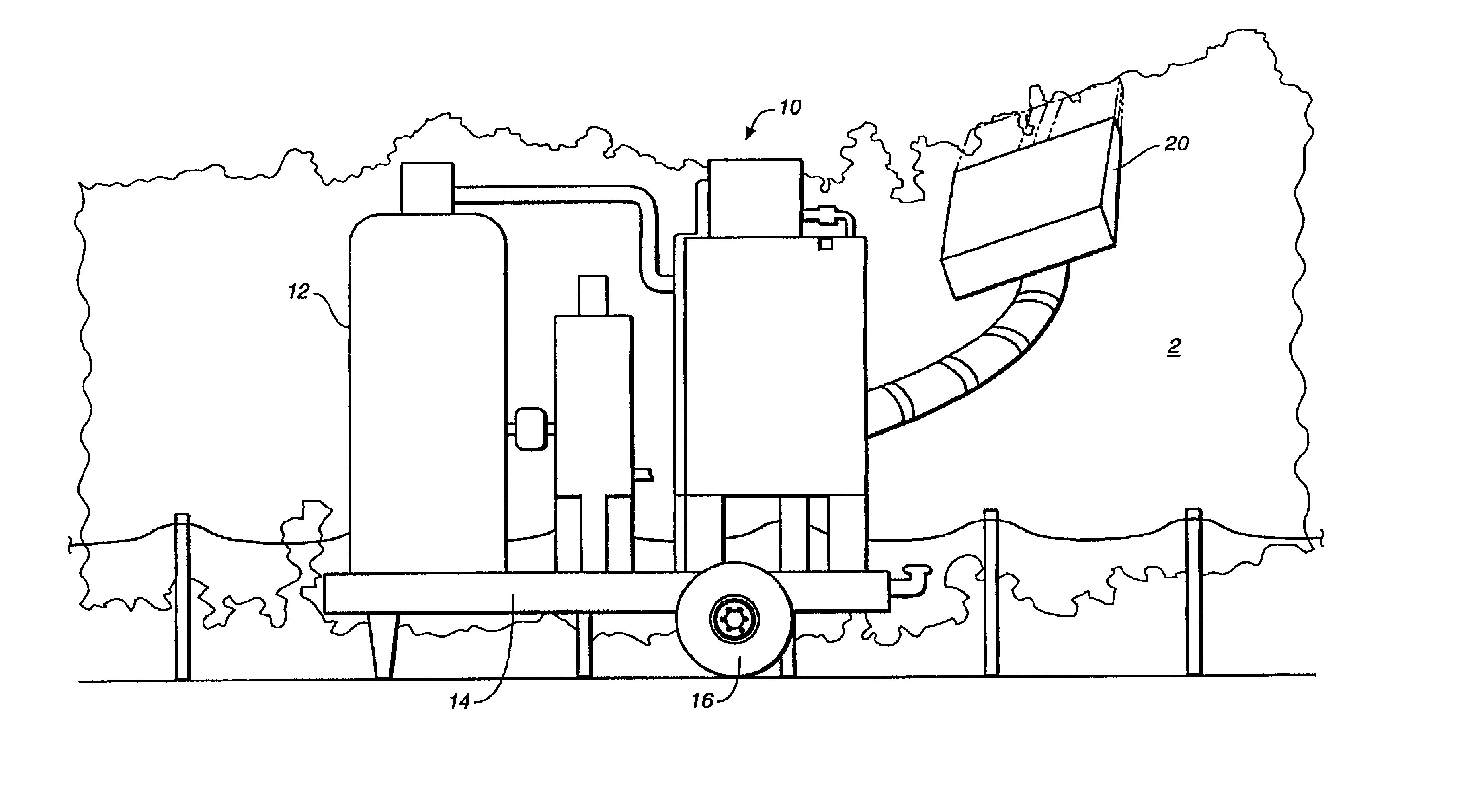

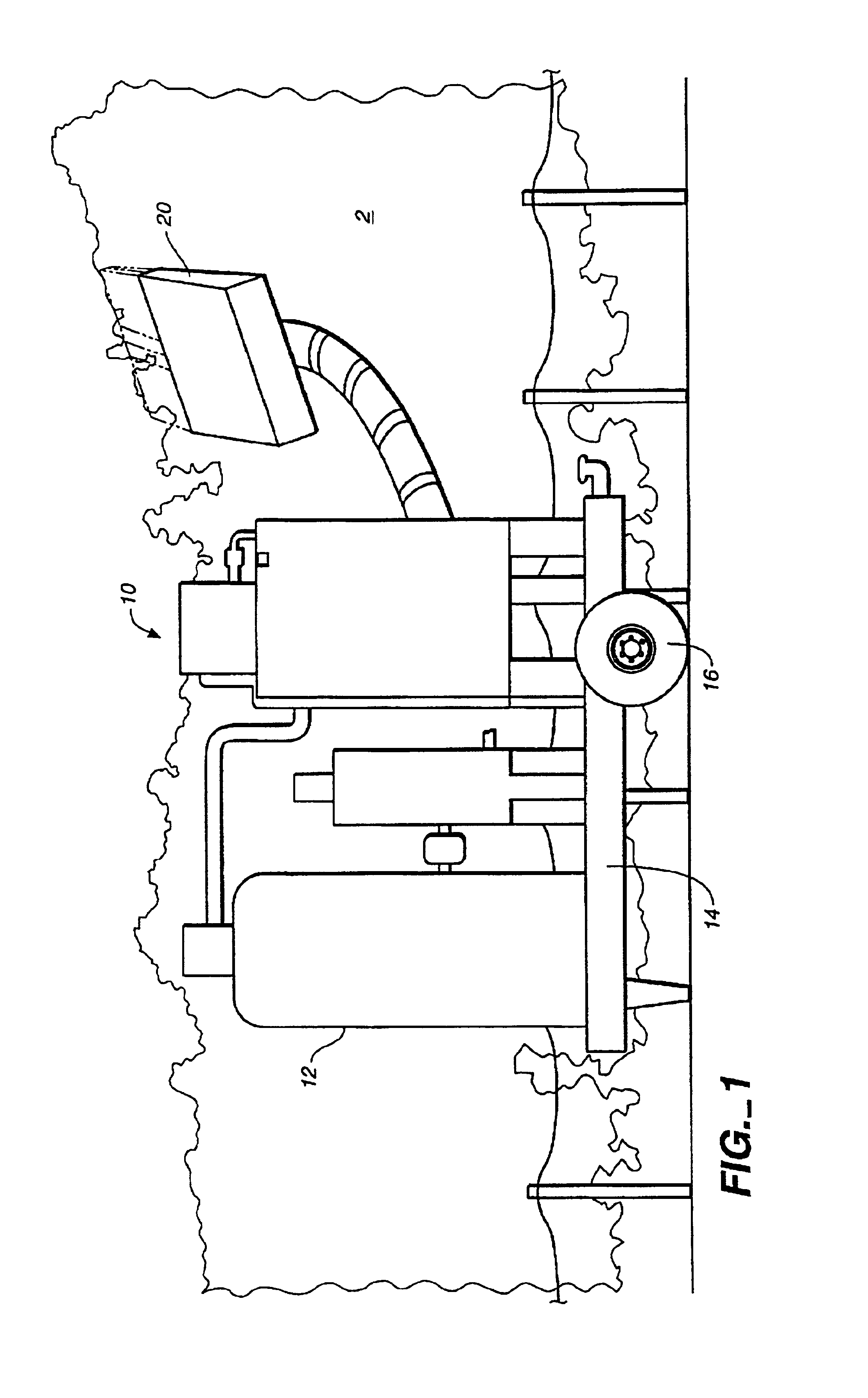

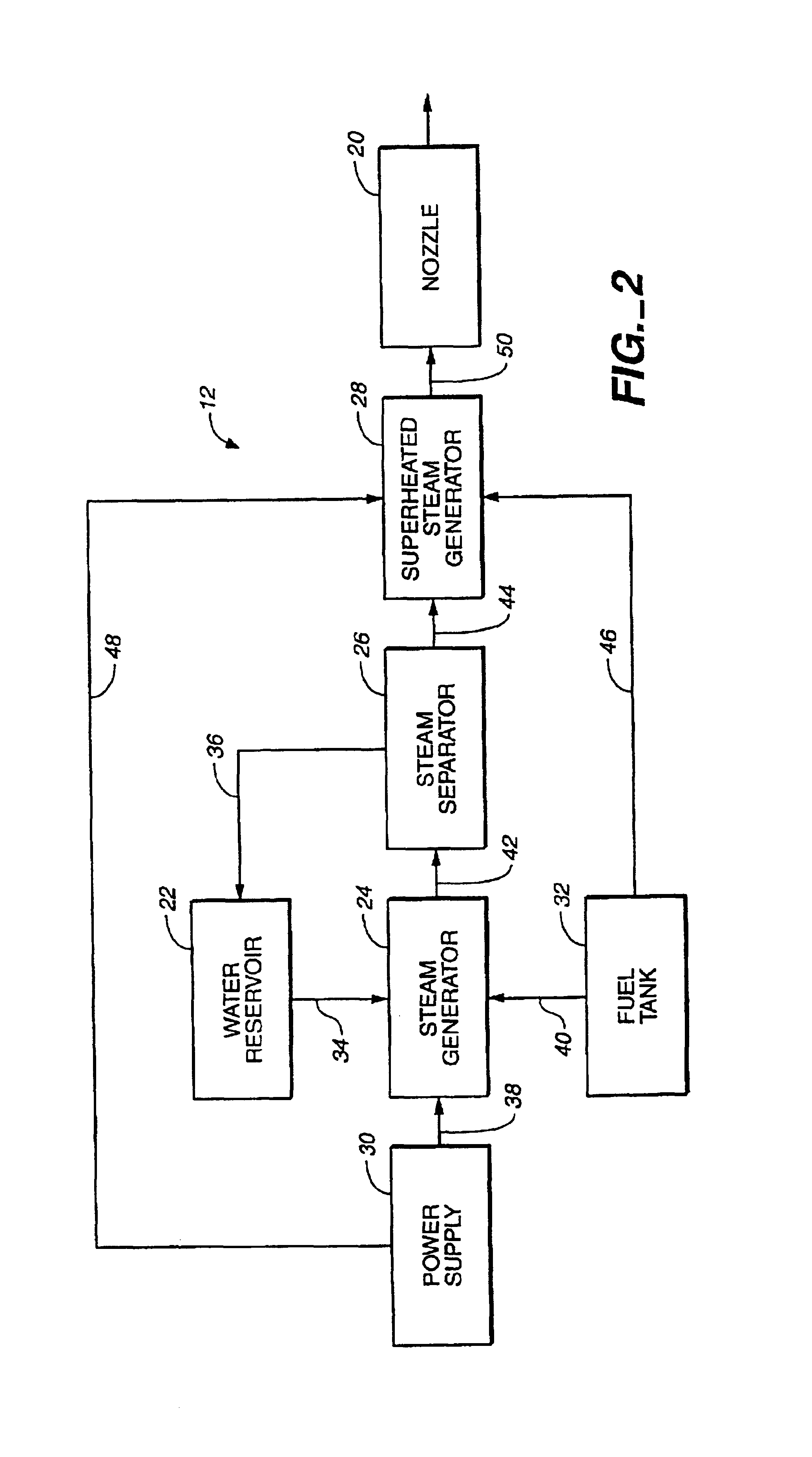

[0069]A prototype of the superheated steam apparatus as described for grape defoliation was pulled by a tractor moving about 1-2 miles per hour through grape vine rows spaced 12 feet apart. With a 300 gallon water reservoir, superheated steam was applied to about 1-2 acres per hour. Within minutes of application, the treated leaves shriveled. The leaves were dry within an hour, followed by leave drop over the next several days. Further, leave hoppers on those directly treated leaves and adjacent leaves were killed and observed to have fallen from the growing vines; however, the developing grape berries were not harmed at all.

example 2

[0070]The top four inches of a worked soil bed had superheated steam applied. Samples of the soil were then inspected and were shown to be substantially sterilized.

example 3

[0071]The prototype of the superheated steam apparatus had the steam nozzle :placed facing down to the row berm of orchard and vineyard rows at a distance 2 inches to 3 inches above the ground and was moved parallel to the ground at between ¼ mph and 1½ mph, depending upon the amount of vegetation to be killed. The superheated steam that was so delivered was in a temperature range of 500° F.-700° F. which was effective to kill the growing weeds and to keep most of the weed seeds that had dropped from germinating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com