Scanning phase measuring method and system for an object at a vision station

a phase measurement and vision station technology, applied in the direction of measuring devices, instruments, material analysis through optical means, etc., can solve the problem of not enough information available to do a phase calculation based on multiple buckets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

case 2

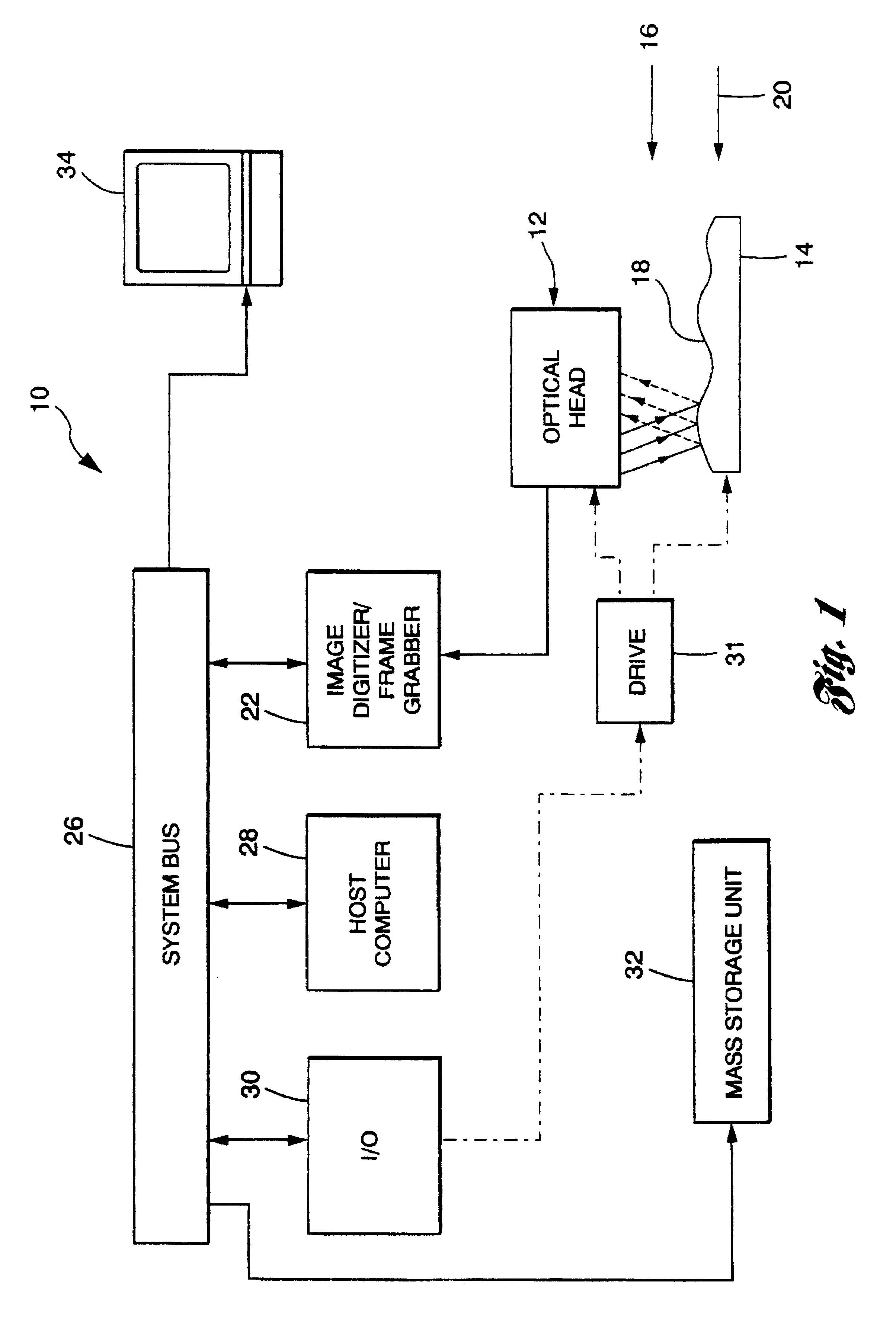

[0039 alluded to above would most likely use a CCD area array in the optical head 1 but could use a linear array or single point photodetector. In this case, as the surface 18 is moved toward or away from the optical head 12, images are taken as the phase of the projection changes. The analysis would consist of correcting for registration between images and then using the images to create the buckets needed for the phase calculation. If the camera images telecentrically or nearly telecentrically, then registration would not be required.

[0040]Systems that employ the Case 2 set-up have been described for use in white light interferometry systems as described in U.S. Pat. Nos. 5,398,113 and 5,355,221 but not for a moire (light stripe) application.

[0041]Although a method is described above for making phase calculations based on a moire (light stripe) system, the described technique could also be applied to any optical base phenomena where the phase is changed between the images created ...

first embodiment

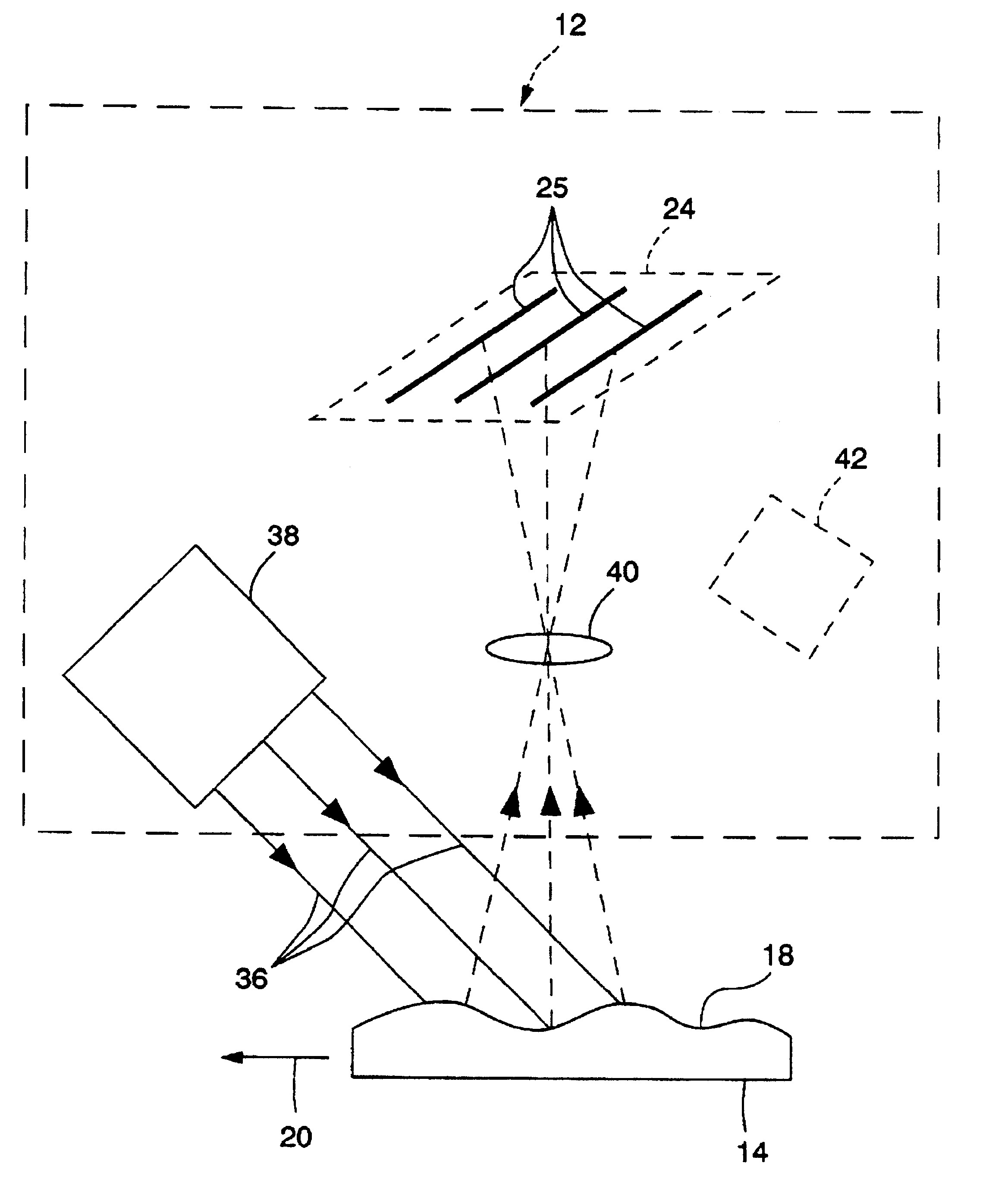

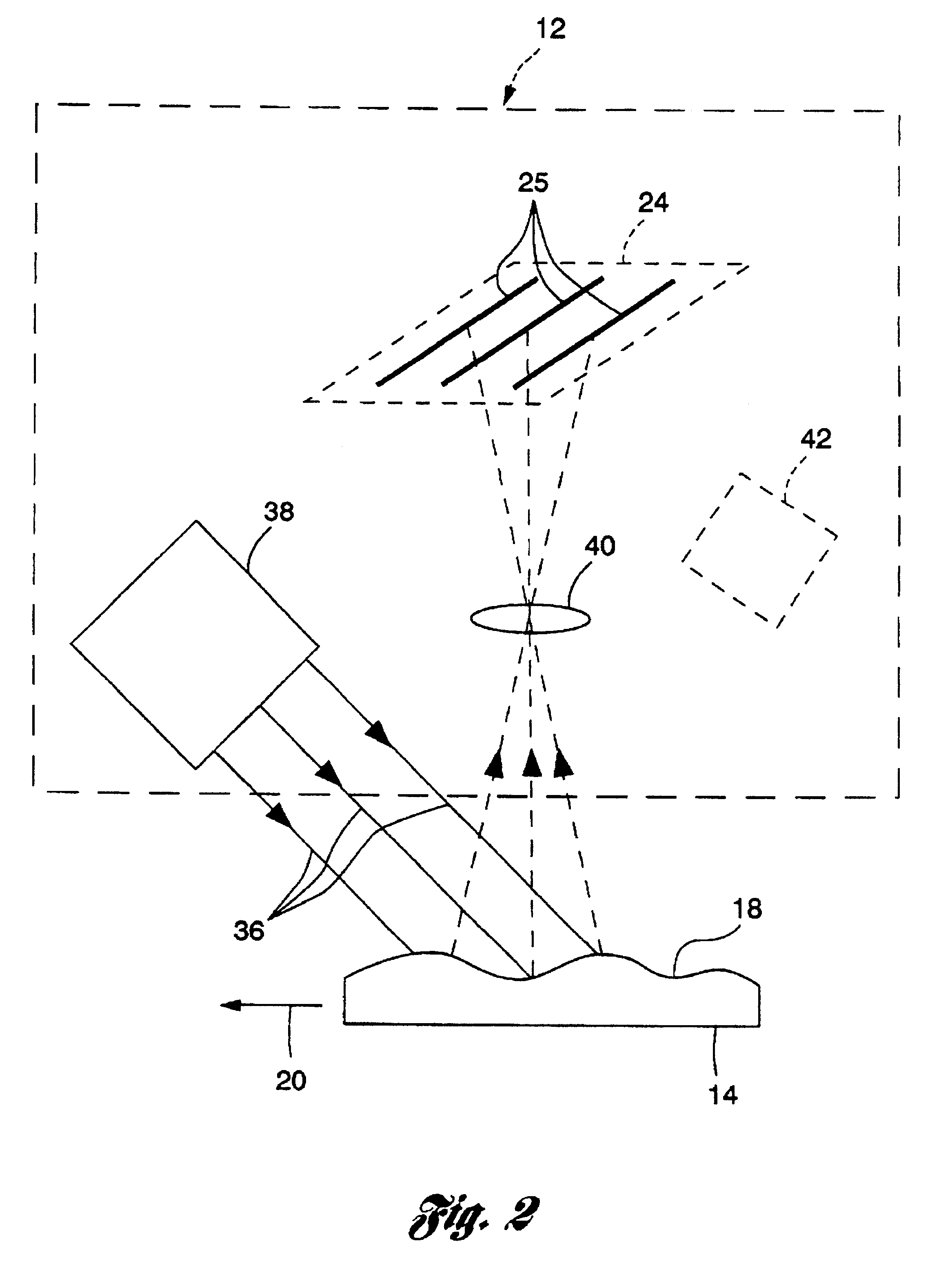

[0056]Referring again to the invention, the optical head 12 includes the light strip projector 28 and the camera includes the imaging lens 40 for focusing the scanned surface onto the trilinear array 24. The scanned surface is translated past the optical head 12 in the direction of the arrow 20. To eliminate perspective effects in both projection and imaging, the project and imaging system should be either telecentric or nearly telecentric. A nearly telecentric system is created by having the standoff from the optics being much larger than the measurement depth range.

[0057]For this discussion, the data from the first linear array in the detector is called b1 (for bucket 1). Likewise, the second and third linear arrays is called b2 and b3, respectively. The pitch of the projected light pattern creates a phase difference of ½ a cycle between b1 and b3. For each linear array, let b1(i,j), b2(i,j) and b3(i,j) designate the light intensity measurement for each linear array with j indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com